Method for degrading azoic dye waste water

A technology for azo dyes and waste water, applied in the direction of adsorption water/sewage treatment, inorganic chemistry, alkali metal compounds, etc., can solve the problems of low efficiency, large amount of sludge, low treatment efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A method for degrading azo dye wastewater, the method is to use an adsorbent to adsorb the azo dye contained in the wastewater. Sorbent among the present invention is that its surface is coated with the hollow glass microsphere of Fe-Ni alloy layer, and this method comprises the steps:

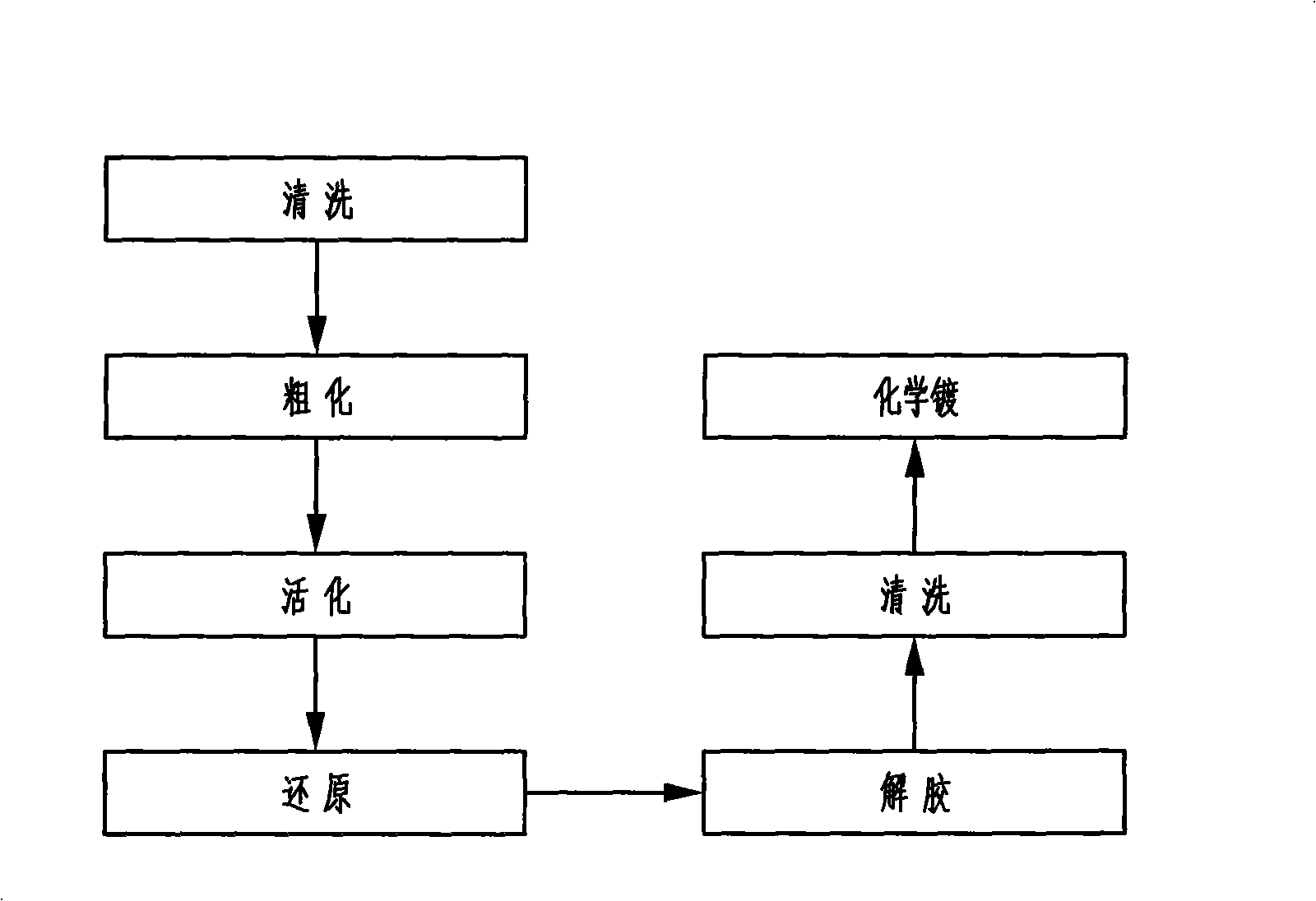

[0016] 1. Carry out modification treatment to hollow glass microspheres (refer to figure 1 )

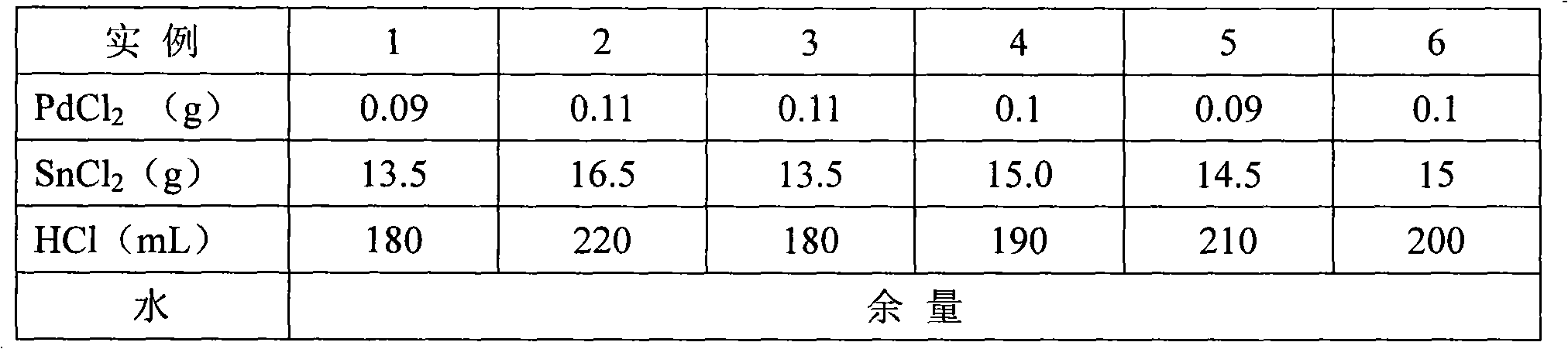

[0017] a. The hollow glass microspheres are pretreated in the order of degreasing cleaning, coarsening, activation, reduction, degumming and post-degumming cleaning;

[0018] B, the surface of the hollow glass microspheres cleaned after degumming, plating Fe-Ni alloy layer with liquid phase chemical plating method, then, cleaning, drying; In Fe-Ni alloy layer, Fe: Ni=1: 2 ~1:4;

[0019] 2. Degradation of azo dye wastewater with modified hollow glass microspheres

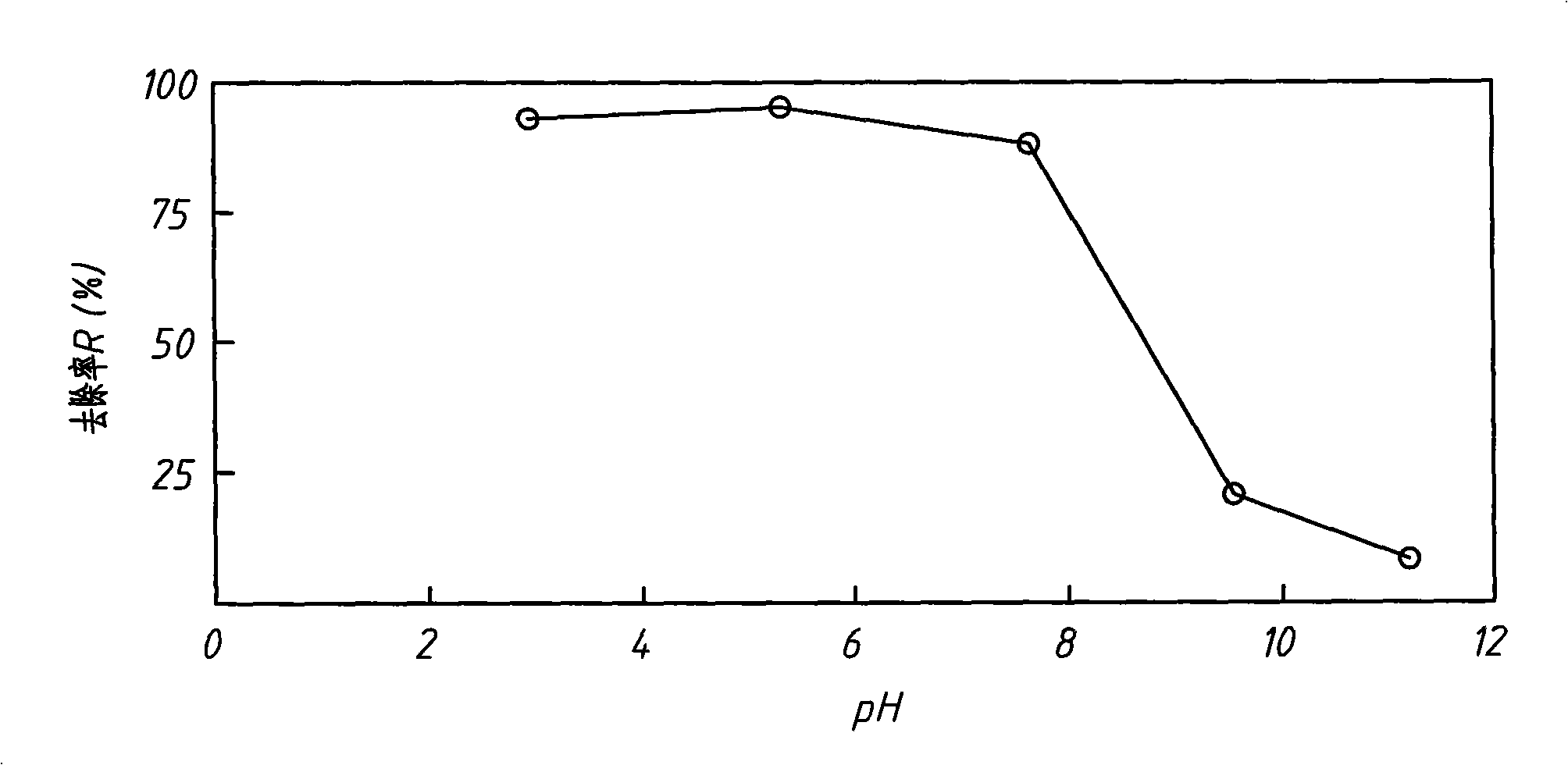

[0020] c. Fully mix the hollow glass microspheres plated with the Fe-Ni alloy layer with the waste water containing azo dyes ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com