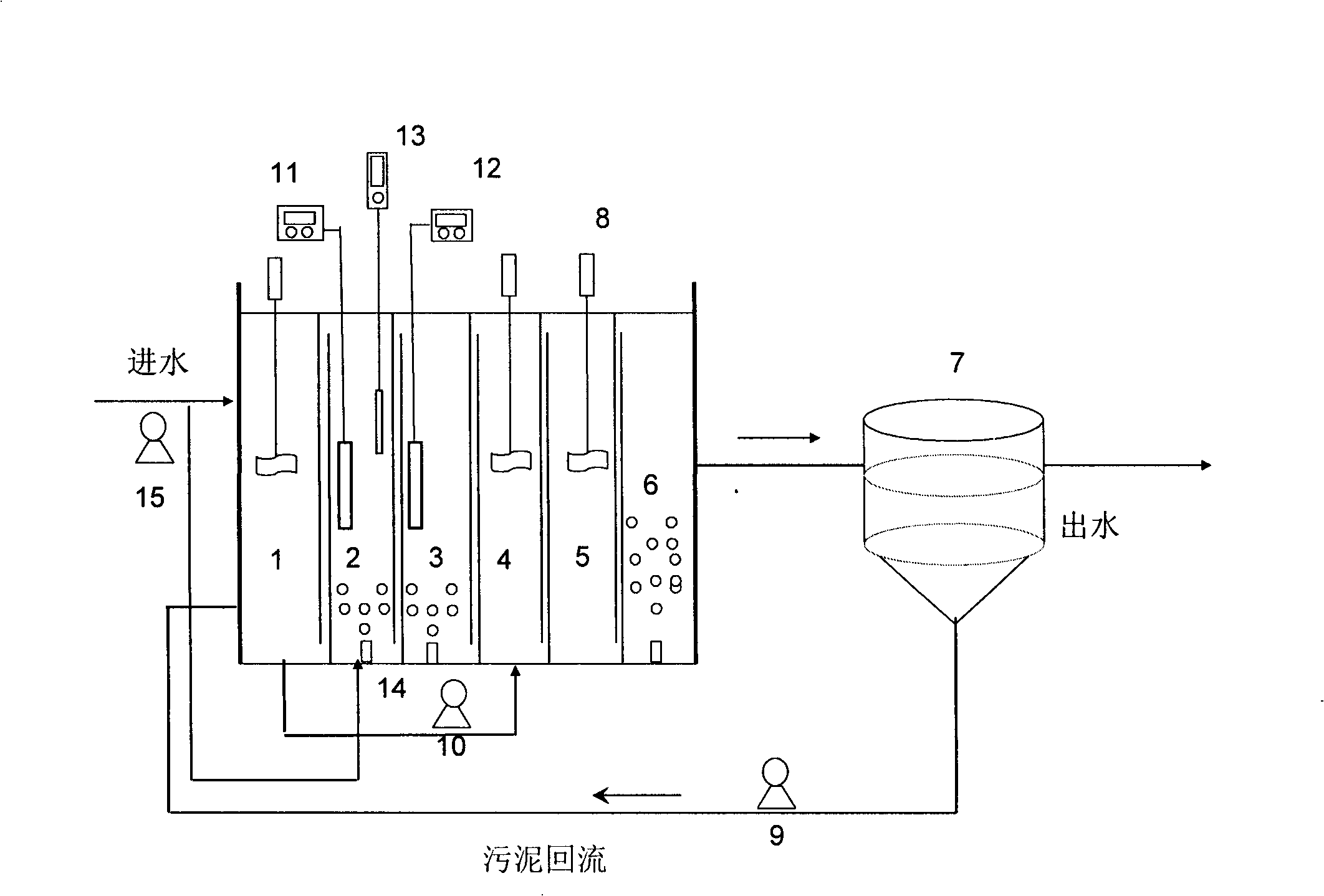

Short-cut denitrification synchronous denitrifying phosphorus removal process and apparatus

A denitrification dephosphorization and denitrification technology, applied in the field of environmental protection and sewage treatment, can solve the problems of poor denitrification and dephosphorization effects, and achieve the goals of prolonging hydraulic retention time, sufficient anaerobic phosphorus release, and realizing energy saving and consumption reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Inoculate the activated sludge from the secondary sedimentation tank of Qinghe Municipal Wastewater Plant into the reactor, and the sludge concentration is about 4000mg / L. The COD concentration of raw sewage is 350-400mg / L, the ammonia nitrogen concentration is 50-60mg / L, and the total phosphorus concentration is 5-8mg / L.

[0029] 40% of the raw sewage enters the anaerobic reactor, and 60% directly enters the first aerobic reactor. The total hydraulic retention time of the system is 9h, the DO of the first aerobic reactor is controlled at 1.0mg / L, the pH is controlled at about 8.0, the DO of the second aerobic reactor is controlled at 0.5mg / L, and the DO in the rapid aeration tank is controlled at 2.0mg / L, the sedimentation time is 0.5h, and the sludge reflux ratio of the sedimentation tank is 100%. After one month of process operation, the system nitrosation rate reaches 70%, the effluent ammonia nitrogen is within 5mg / L, the effluent COD is within 20mg / L, and the eff...

Embodiment 2

[0031] Inoculate the activated sludge from the secondary sedimentation tank of Qinghe Municipal Wastewater Plant into the reactor, and the sludge concentration is about 4000mg / L. The COD concentration of raw sewage is 350-400mg / L, the ammonia nitrogen concentration is 50-60mg / L, and the total phosphorus concentration is 5-8mg / L.

[0032] 60% of the raw sewage enters the anaerobic reactor, and 40% directly enters the first aerobic reactor. The total hydraulic retention time of the system is 11 hours, the DO of the first aerobic reactor is controlled at 1.50 mg / L, the pH is controlled at about 8.0, the DO of the second aerobic reactor is controlled at 0.3 mg / L, and the DO in the rapid aeration tank is controlled at 5.0 mg / L, the sedimentation time is 0.50h, and the sludge reflux ratio of the sedimentation tank is 70%. After one month of process operation, the system nitrosation rate reaches 60%, the effluent ammonia nitrogen is within 5mg / L, the effluent COD is within 20mg / L, ...

Embodiment 3

[0034] Inoculate the activated sludge from the secondary sedimentation tank of Qinghe Municipal Wastewater Plant into the reactor, and the sludge concentration is about 4000mg / L. The COD concentration of raw sewage is 350-400mg / L, the ammonia nitrogen concentration is 50-60mg / L, and the total phosphorus concentration is 5-8mg / L.

[0035] 50% of the raw sewage enters the anaerobic reactor, and 50% directly enters the first aerobic reactor. The total hydraulic retention time of the system is 10h, the DO of the first aerobic reactor is controlled at 1.30mg / L, the pH is controlled at about 8.0, the DO of the second aerobic reactor is controlled at 0.3mg / L, and the DO in the rapid aeration tank is controlled at 4.0mg / L, the sedimentation time is 0.50h, and the sludge reflux ratio of the sedimentation tank is 80%. After one month of process operation, the system nitrosation rate reaches 50%, the effluent ammonia nitrogen is within 5mg / L, the effluent COD is within 20mg / L, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com