Hydrogen making Al base alloy composite materials, preparation and process of using thereof

A composite material and base alloy technology, applied in the field of hydrogen energy, can solve problems such as difficult storage, transportation, high activity, slow reaction speed, etc., and achieve the effects of improving hydrogen production efficiency, long duration, and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

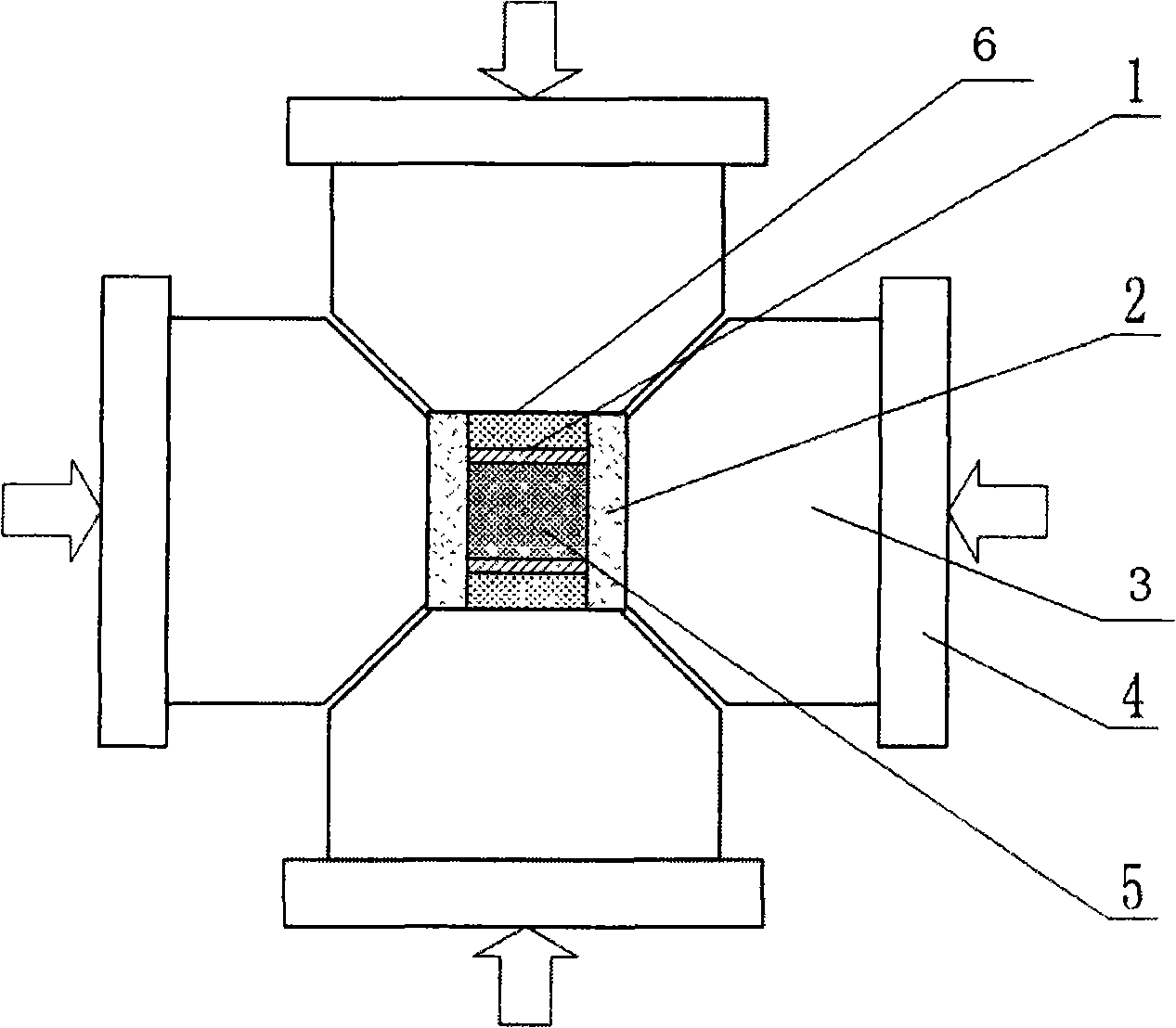

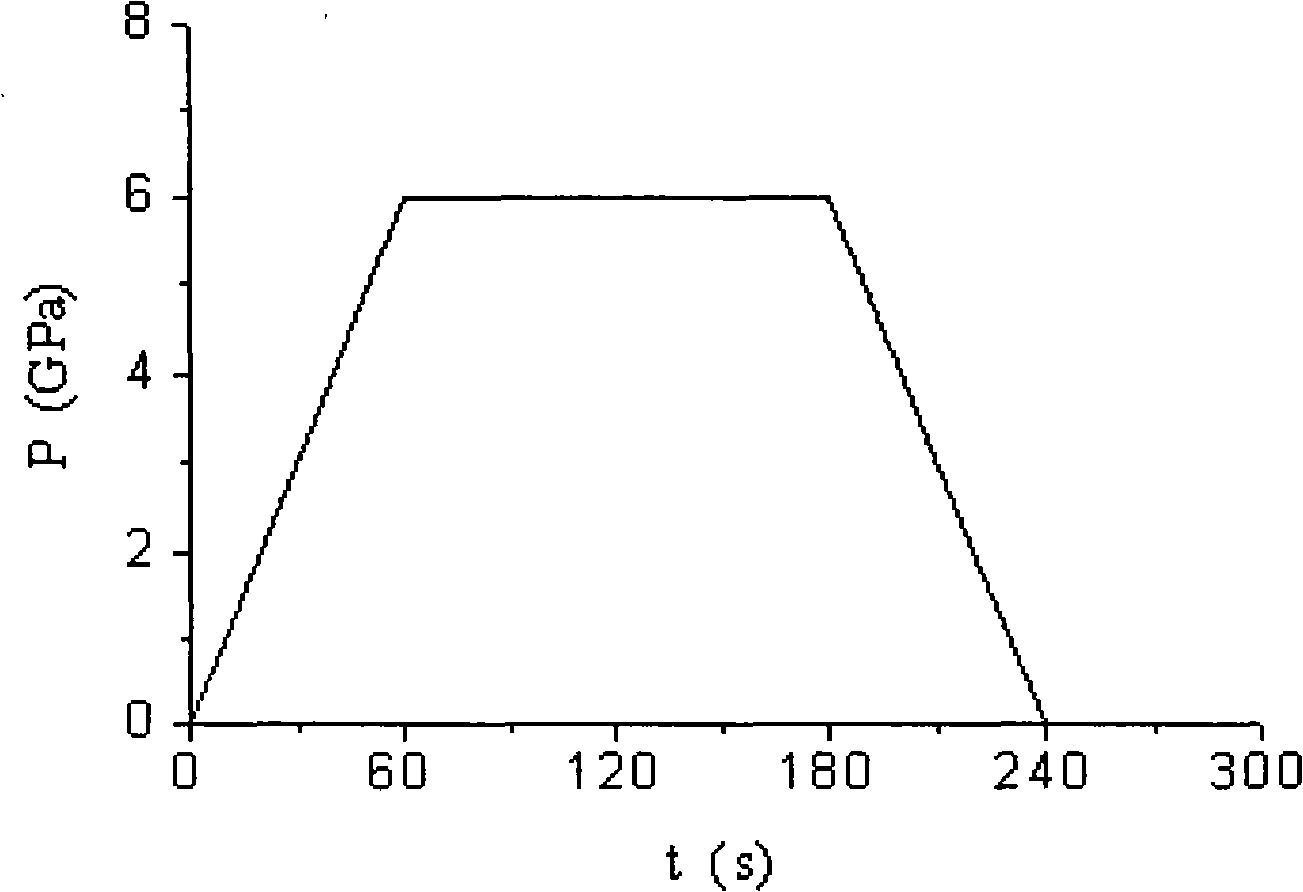

[0030] Al-Sn / CNTs composites were prepared by high temperature and high pressure method. Al-Sn alloy containing 27wt% Al is smelted and Al-Sn alloy powder is made by a certain method. The size of the powder can vary from 100nm to 1mm. In this example, the size of the powder is about 0.1mm. Multi-walled carbon nanotubes (MWNTs) are prepared by chemical vapor deposition (CVD). These MWNTs have certain orientation and contain a certain proportion of amorphous carbon. According to the ratio of carbon nanotubes to 3% of the mass ratio of the composite material, the carbon nanotubes and Al-Sn alloy powder were mixed and ground for 30 minutes, and then put into the molybdenum cup 5 with a cover. Then, if figure 1 As shown, put the molybdenum cup 5 into the pyrophyllite 2 that is approximately cubic (see figure 1), pyrophyllite 2 is a thermoelectric insulator and is used to transmit pressure. The pyrophyllite 2 has circular openings in two opposite directions into which the molybde...

Embodiment 2

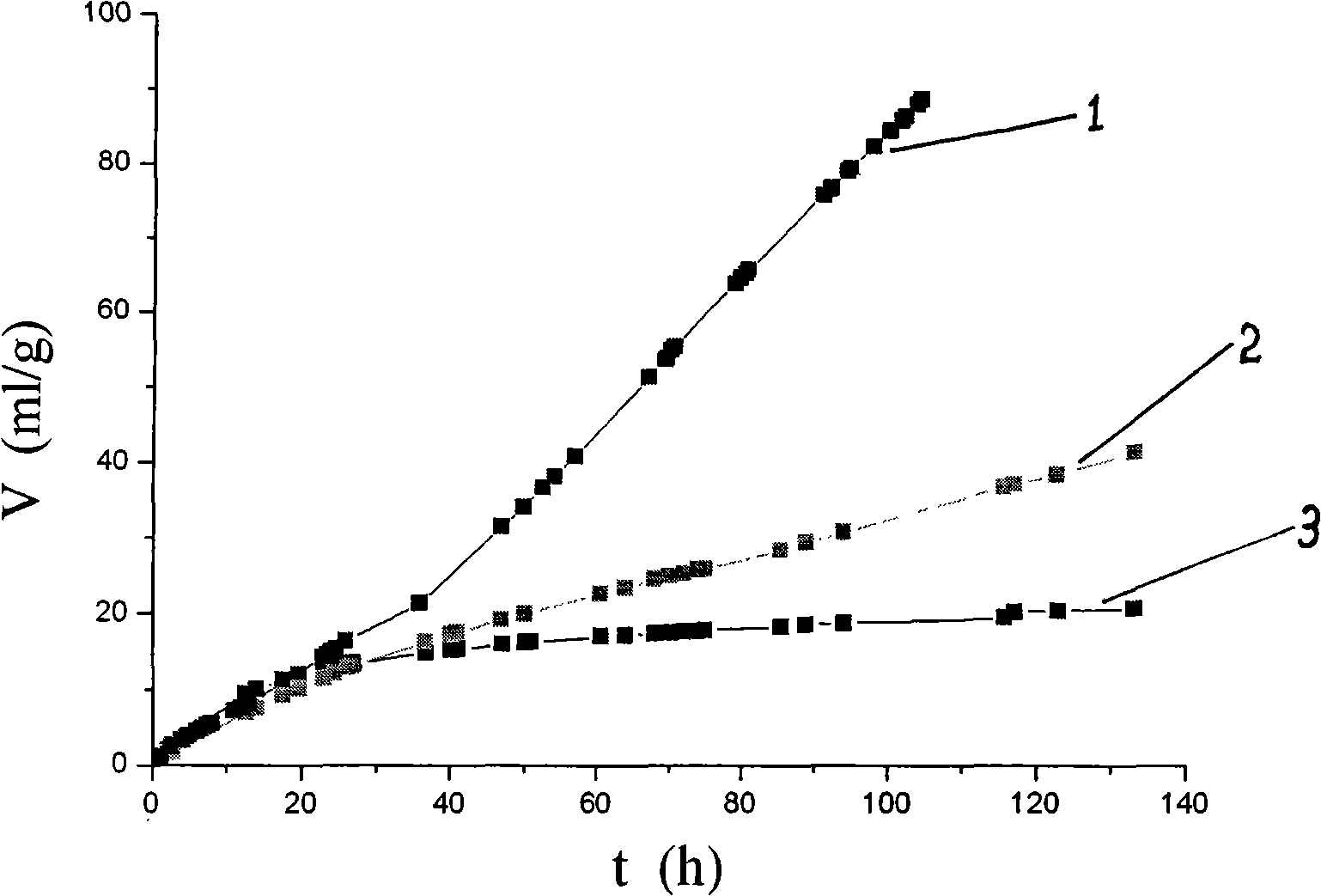

[0032] The preparation method of the composite material of this embodiment (wherein the Al-Sn alloy used is an Al-Sn alloy containing 27wt% Al) is basically the same as that of Embodiment 1, the difference is that when the raw materials are taken, the carbon nanotubes account for the composite material. The ratio of finished product mass to 6% is taken, and the color of the composite material of the finished product is darker than that of the finished product in Example 1. The composite material of the finished product of this embodiment can also directly react with water at room temperature, and the volume of hydrogen gas produced by the reaction of the unit mass of Al-Sn / CNTs composite material sample with water is as follows: image 3 Shown in curve 1. Depend on image 3 It can be seen that the reaction speed of the finished composite material and water increases with the increase of the proportion of CNTs content in the composite material.

Embodiment 3

[0034] In this example, Al-Sn / CNTs composite material is prepared by vacuum suction casting method. Firstly, the carbon nanotubes in Example 1 are pressed into a cylindrical carbon nanotube framework under a certain pressure, and the relative density of the framework increases with the increase of the pressure. The used Al-Sn alloy contains 75wt% Al, and after the alloy is melted, the melt is sucked into the voids of the carbon nanotube skeleton by vacuum suction casting to form the Al-Sn / CNTs composite material. The mass percentage of carbon nanotubes in the composite material obtained by this method can reach 25wt%, and the maximum speed of the reaction between the obtained composite material and water to generate hydrogen is 2-100 times greater than that of the corresponding alloy without adding carbon nanotubes and water. times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com