Method for preparing nano CMOS integrated circuit by SiO2 masking technique

An integrated circuit, nano-scale technology, applied in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as waste of resources and energy, restrict the development of the semiconductor industry, etc., achieve a small conductive channel, achieve leapfrog development, Achieving processing-level effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

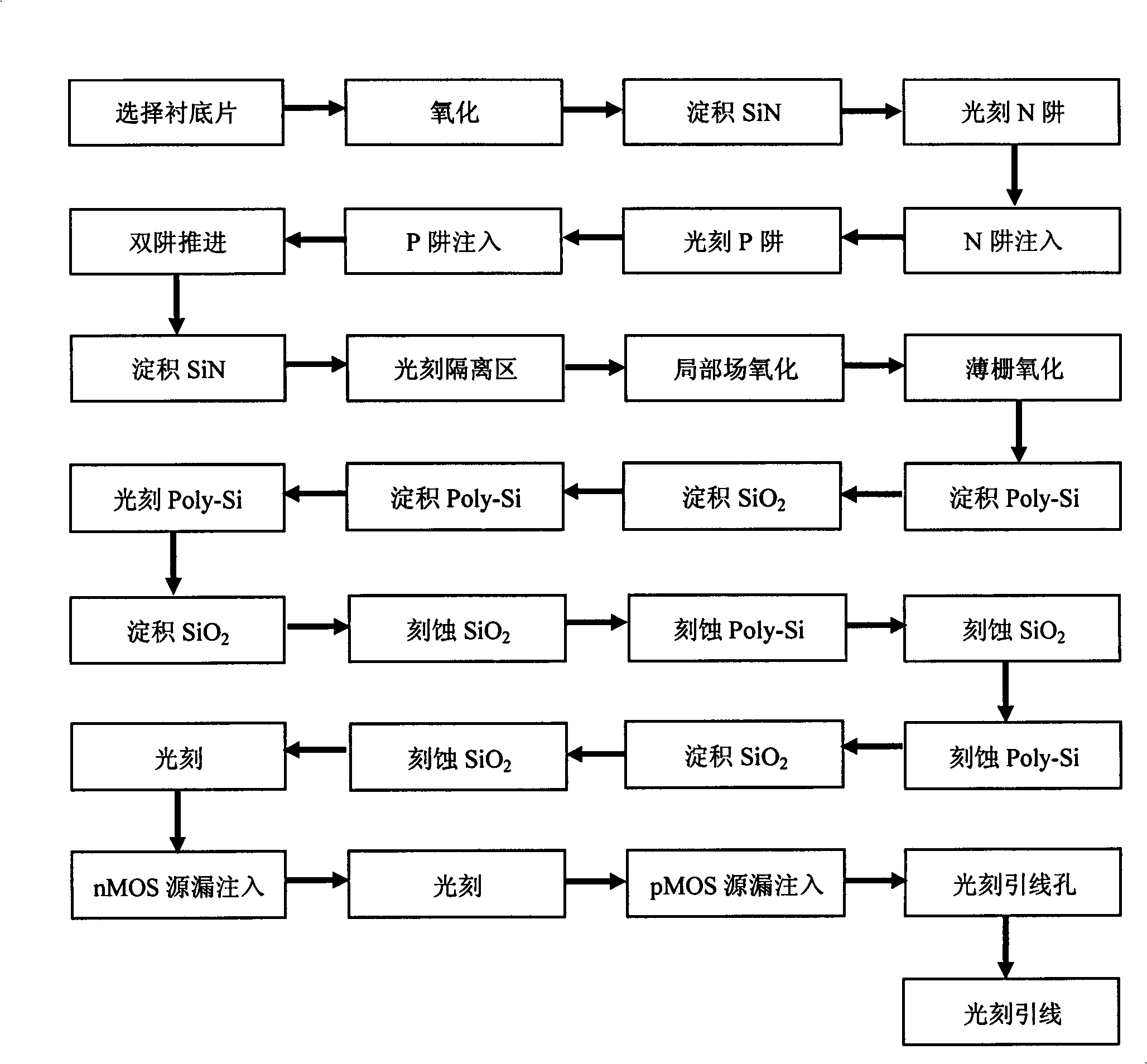

[0030] Embodiment 1: prepare the CMOS integrated circuit that conduction channel is 75nm on Si substrate, concrete steps are as follows:

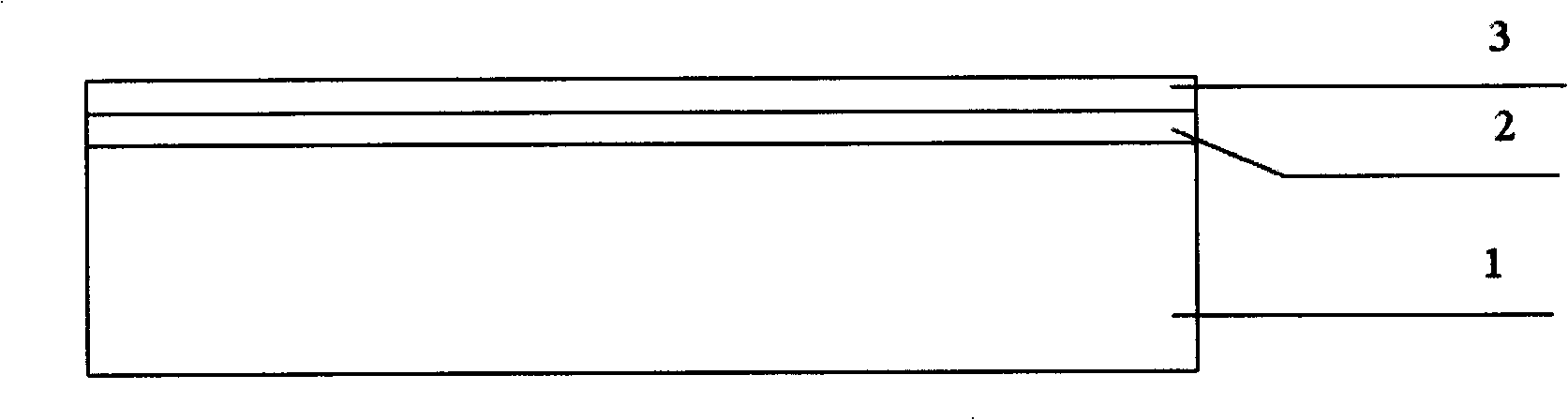

[0031] Step 1, depositing a masking layer, as shown in Figure 2(a).

[0032] (1a) Select the crystal orientation as and the doping concentration as 10 15 cm -3 Left and right p-type Si substrate sheets 1;

[0033] (1b) Thermally oxidize a layer of SiO with a thickness of 40 nm on the substrate 2 buffer layer 2;

[0034] (1c) on SiO 2 A 100nm thick SiN layer 3 is deposited on the buffer layer by plasma-enhanced chemical vapor deposition (PECVD) for masking implantation in the well region.

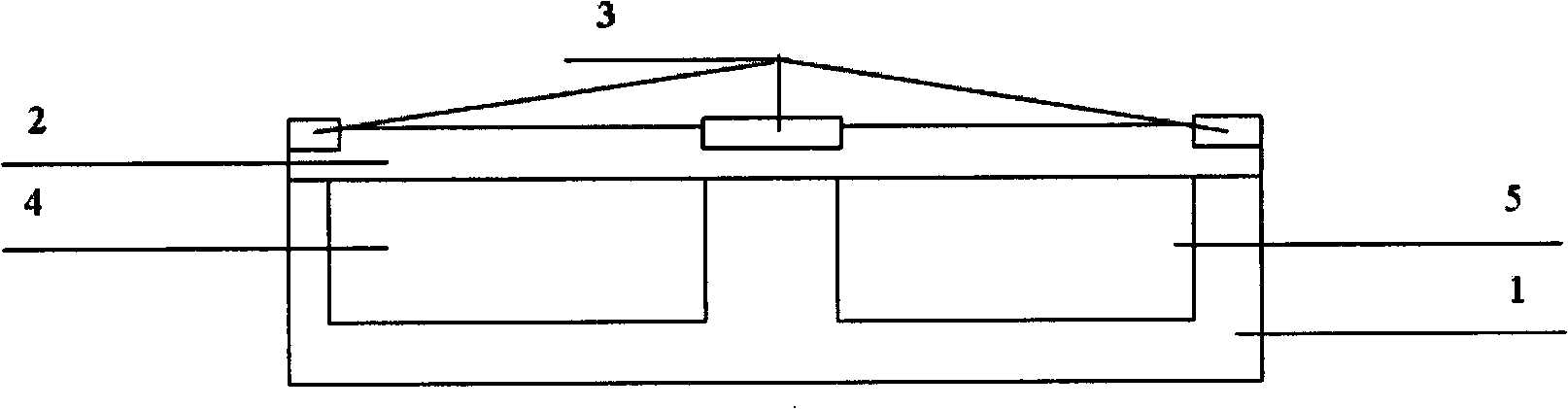

[0035] Step 2, forming a well region, as shown in FIG. 2(b).

[0036] (2a) Photoetching the P well region 4 and the N well region 5 on the SiN layer 3 according to the phase sequence;

[0037] (2b) Boron is implanted in the P well region to form a p-type region, and SiO is thermally oxidized on the surface of the P well region 2 , while advancing...

Embodiment 2

[0065] Embodiment 2: prepare the CMOS integrated circuit that conduction channel is 65nm on SOI substrate, concrete steps are as follows:

[0066] Step 1, depositing a masking layer, as shown in Figure 2(a).

[0067] (1a) Select the crystal orientation as and the doping concentration as 10 15 cm -3 left and right p-type SOI substrates 1;

[0068] (1b) Thermally oxidize a layer of SiO with a thickness of 40 nm on the substrate 2 buffer layer 2;

[0069] (1c) on SiO 2 A 150nm-thick SiN layer 3 is deposited on the buffer layer by means of atmospheric pressure chemical vapor deposition APCVD, which is used for the masking of well region implantation.

[0070] Step 2, forming a well region, as shown in FIG. 2(b).

[0071] (2a) Photoetching the P well region 4 and the N well region 5 on the SiN layer 3 according to the phase sequence;

[0072] (2b) Boron is implanted in the P well region to form a p-type region, and SiO is thermally oxidized on the surface of the P well regi...

Embodiment 3

[0100] Embodiment 3: prepare the CMOS integrated circuit that conduction channel is 90nm on Si substrate, concrete steps are as follows:

[0101] Step 1, depositing a masking layer, as shown in Figure 2(a).

[0102] (1a) Select the crystal orientation as and the doping concentration as 10 15 cm -3 Left and right p-type Si substrate sheets 1;

[0103] (1b) Thermally oxidize a layer of SiO with a thickness of 60 nm on the substrate 2 buffer layer 2;

[0104] (1c) on SiO 2 A 200nm-thick SiN layer 3 is deposited on the buffer layer by low-pressure chemical vapor deposition (LPCVD) for masking of well implantation.

[0105] Step 2, forming a well region, as shown in FIG. 2(b).

[0106] (2a) Photoetching the P well region 4 and the N well region 5 on the SiN layer 3 according to the phase sequence;

[0107] (2b) Boron is implanted in the P well region to form a p-type region, and SiO is thermally oxidized on the surface of the P well region 2 , while advancing the P well, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com