Special shape tissue engineering bracket and construction method and use thereof

A tissue engineering scaffold and a technology with a specific shape, which are applied in the field of tissue engineered cartilage preparation, can solve problems such as being unfavorable for industrialized production, complex modeling of an all-external nose model stent, and unfavorable for the construction of bone marrow stromal stem cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Fabrication of personalized auricle prosthetic bracket

[0095] Materials and methods

[0096] 1. Materials

[0097] 1.1 Equipment

[0098] 16-slice spiral CT (GE LIGHT SPEED 16 SLICES) purchased from General Corporation; medical tomography processing software purchased from Shanghai Jiaotong University; rapid prototyping machine purchased from Z CORPORATION.

[0099] 1.2 Clinical medical records

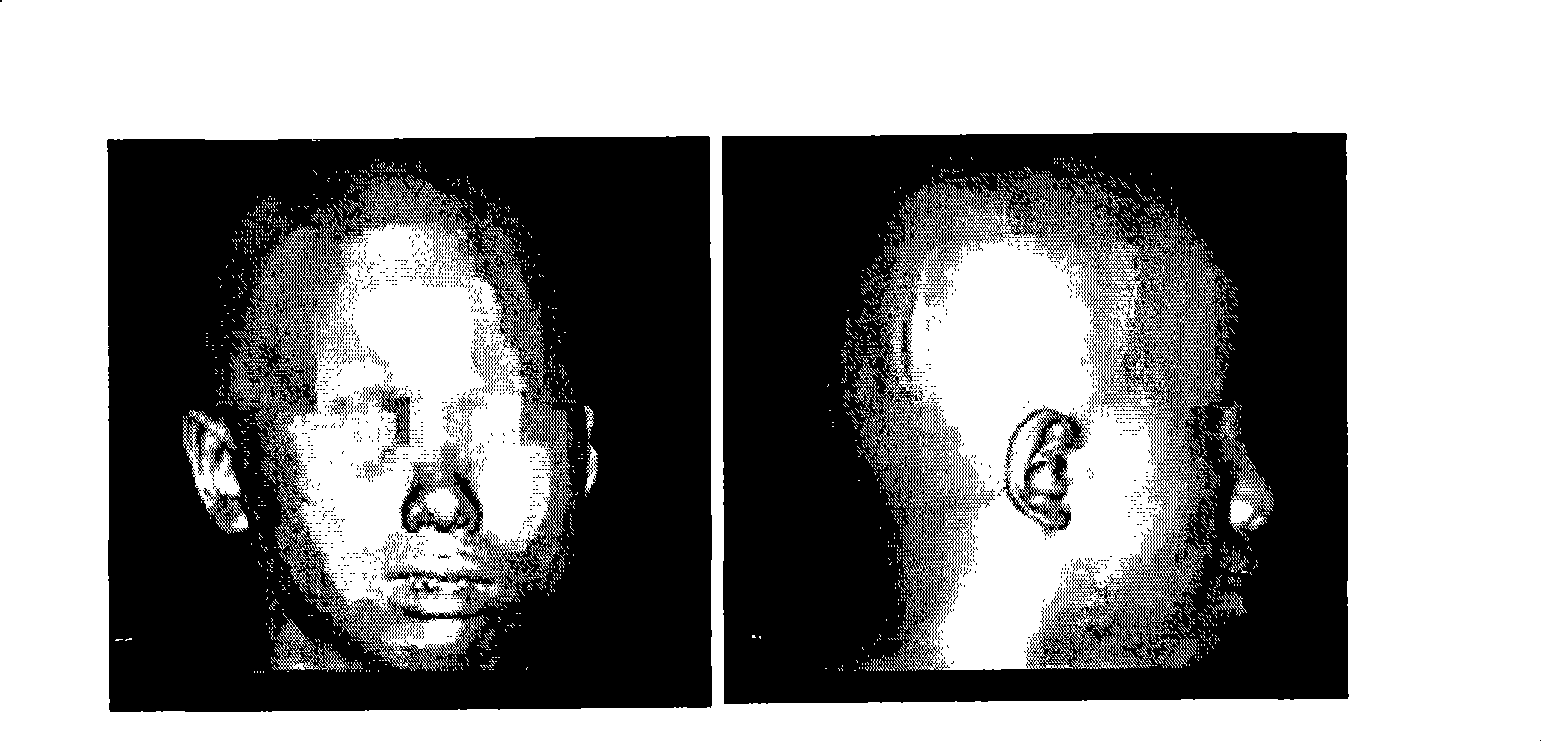

[0100] Randomly selected 3 clinical cases of microtia from the Department of Plastic and Reconstructive Surgery of the Ninth People's Hospital Affiliated to Shanghai Jiao Tong University School of Medicine.

[0101] 2. Method

[0102] 2.1 CT scan

[0103] The whole head of case A was scanned with continuous thin-slice CT volume. The scanning equipment is a 16-slice spiral CT of the American General Company, each slice is 0.625mm, and an average of 136 slices. The rotation angle is 216°, and the exposure time is 0.1S. All the images are transmitted to the graphics work...

Embodiment 2

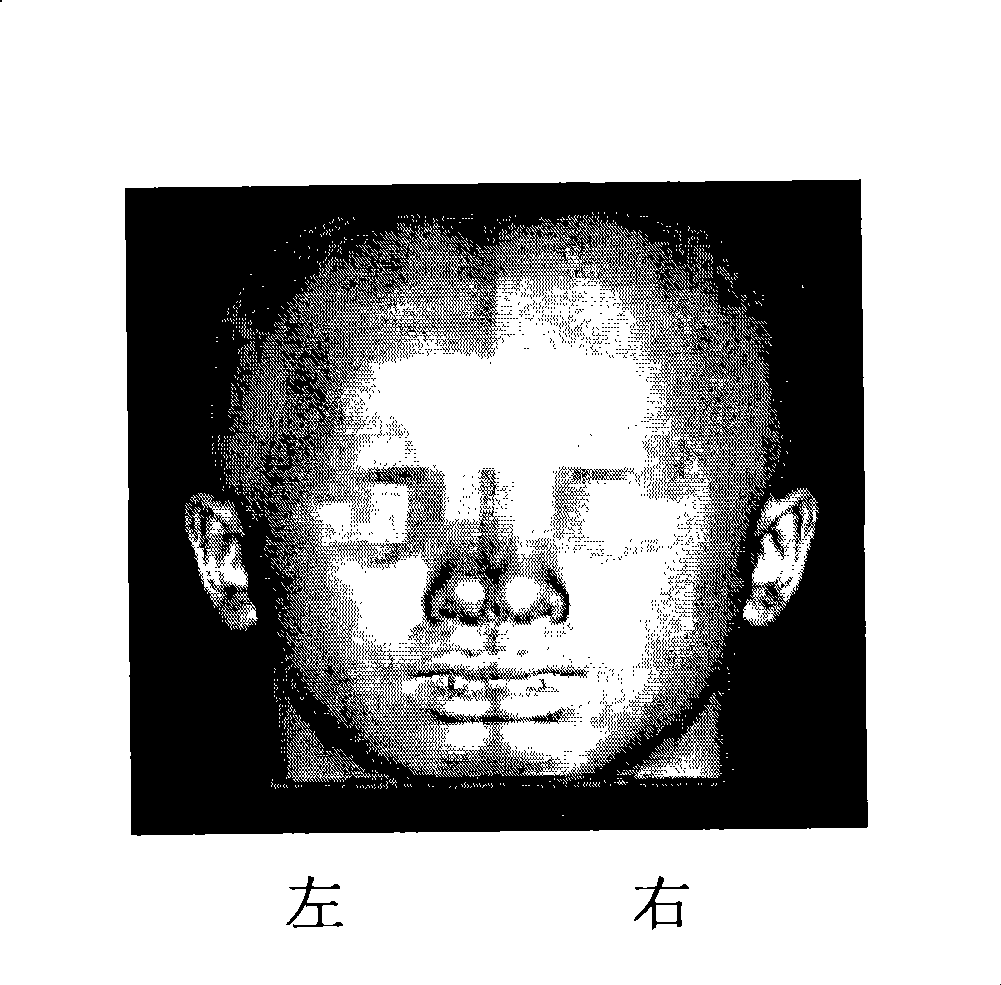

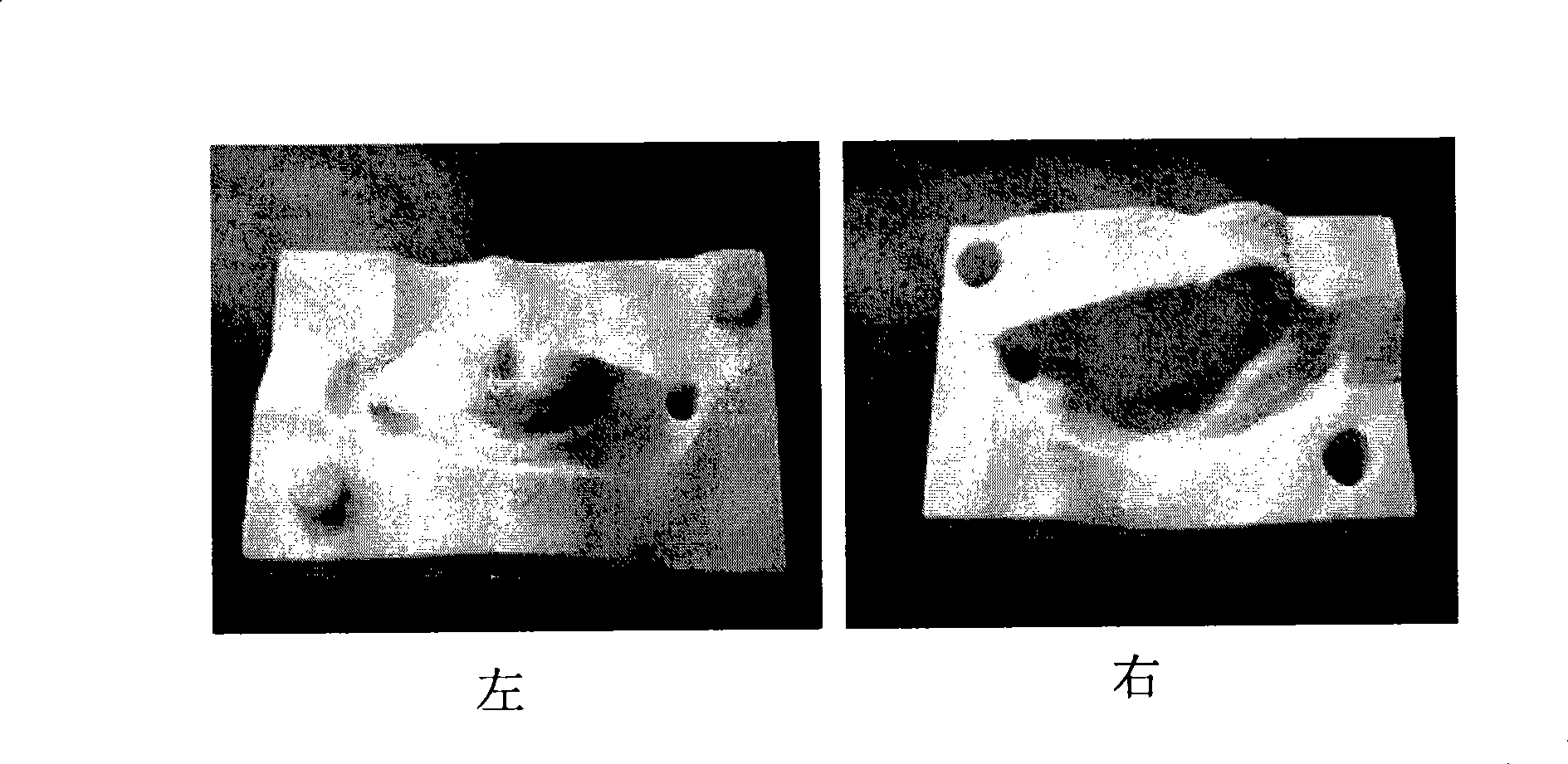

[0122] Fabrication of personalized external nasal restorations

[0123] Materials and methods

[0124] 1. Materials

[0125] 1.1 Equipment

[0126] 16-slice spiral CT (GE LIGHT SPEED 16 SLICES) purchased from General Corporation; medical tomography processing software purchased from Shanghai Jiaotong University; rapid prototyping machine (SpectrumZ510) purchased from Z CORPORATION.

[0127] 1.2 Clinical medical records

[0128] Randomly selected 3 clinical cases of plastic surgery in Ninth People's Hospital Affiliated to Shanghai Jiaotong University School of Medicine.

[0129] 2. Method

[0130] 2.1 CT scan

[0131] In this case, serial thin-slice CT volume scans were performed on the whole head. The scanning equipment is a 16-slice spiral CT of the American General Company, each slice is 0.625mm, and an average of 136 slices. The rotation angle is 216°, and the exposure time is 0.1S. All the images are transmitted to the graphics workstation of GE Company through the...

Embodiment 3

[0148] Fabrication of cartilage for auricle restoration

[0149] Carry out electron microscope scanning to the auricle prosthesis bracket that embodiment 1 makes, determine optimal PLA: (PGA+PLA) ratio ( Figure 8 , 9 ), the result is preferably 20%-30%. Composite the porcine chondrocytes with the above-mentioned auricle prosthetic scaffold, wherein the concentration of porcine chondrocytes in the complex is 5×10 7 cells / cm 3 . They were cultured in vitro, and samples were collected at 4 weeks, 8 weeks and 12 weeks respectively. Histological evaluation (mass morphology, HE staining, Saffranin'0 staining and type II collagen immunohistochemical staining) was performed. See Figure 10 .

[0150] The results show that auricular grafts with individualized shapes can be obtained.

[0151] discuss

[0152] Chondrocytes are the earliest and most commonly used seed cells in tissue engineering cartilage research. However, obtaining cells from the body's own cartilage tissue wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com