Pre-compressing device for processing and fixing the honeycomb flexible material

A flexible material, pre-compression technology, used in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high cost of diaphragm method, cancer, poor retention reliability, poor stability, etc., to improve the honeycomb clamping Accuracy, Interference Avoidance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

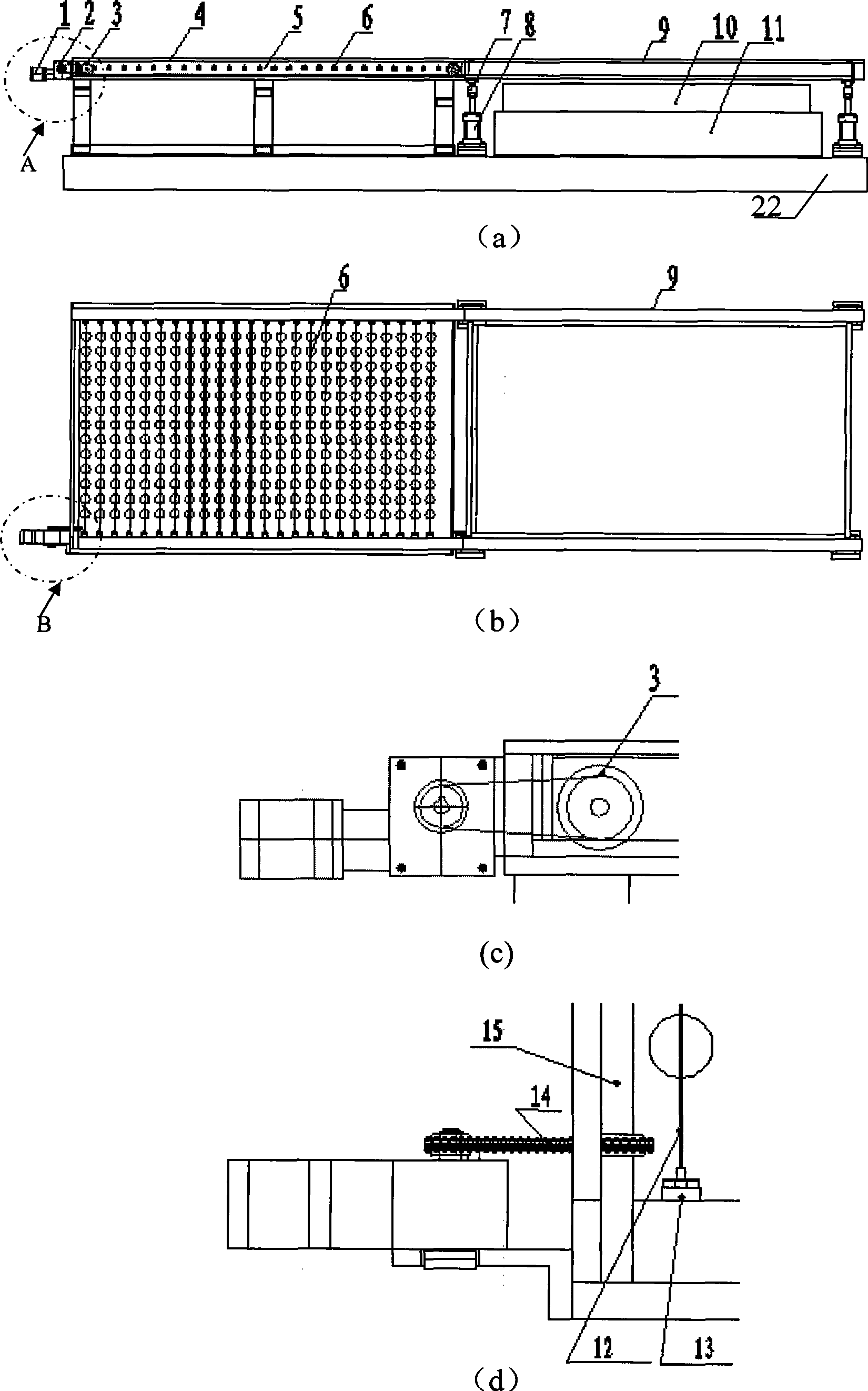

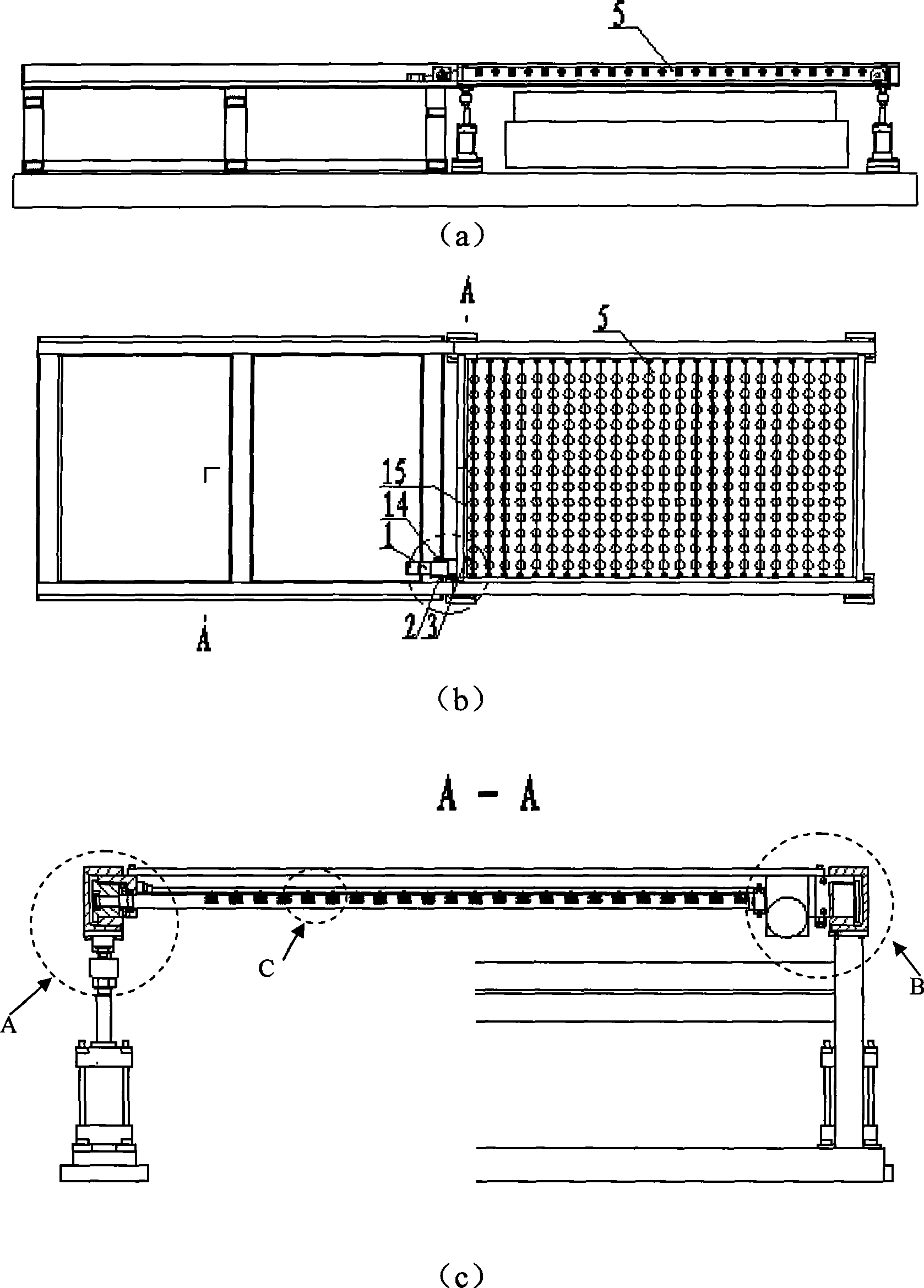

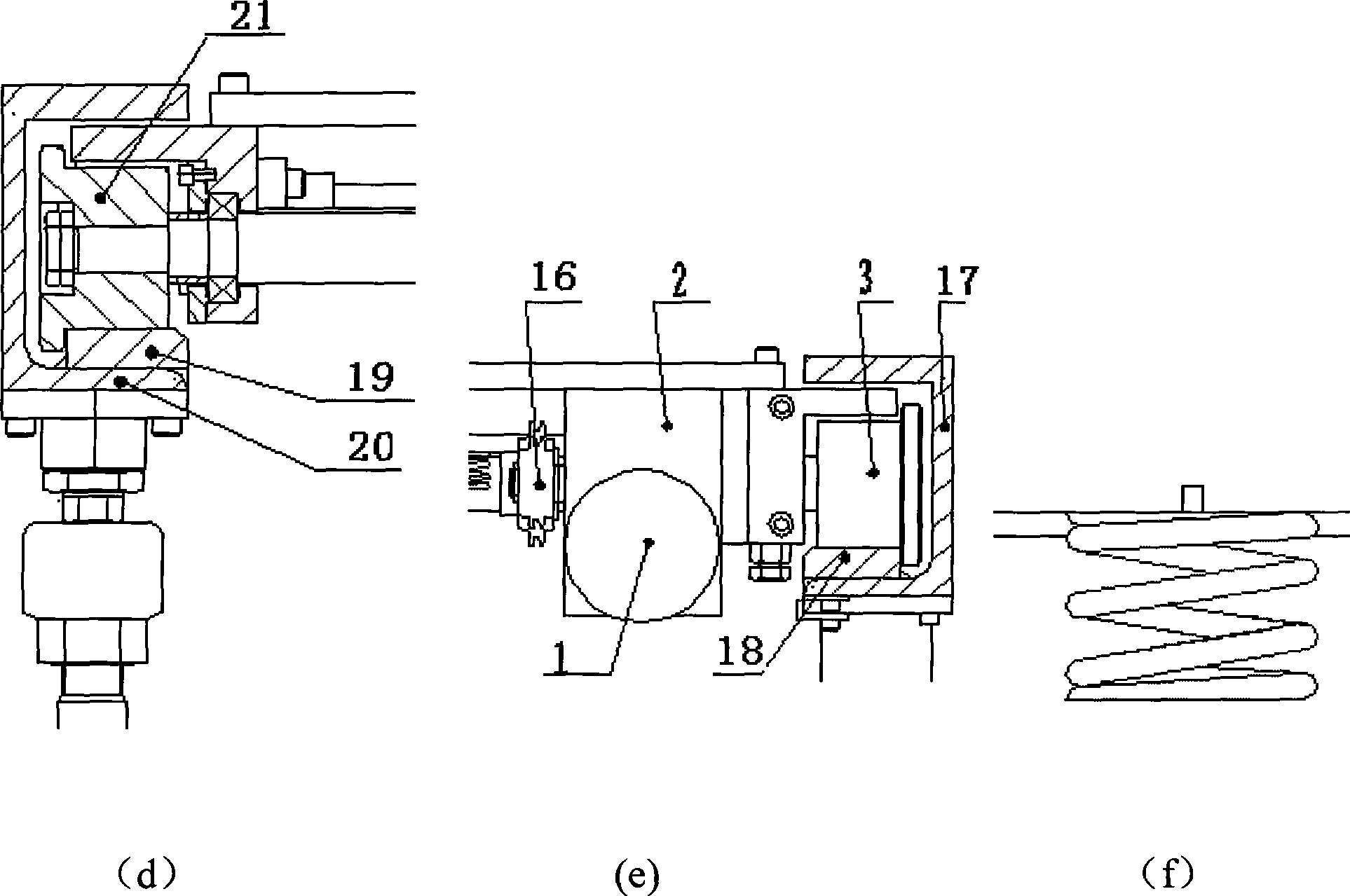

[0020] Such as figure 1 As shown, the pre-compression device for processing and holding honeycomb flexible materials includes a stepping motor 1, a worm gear reducer 2, a first roller 3, a fixed bracket 4, a moving compression frame 5, a spring 6, a floating joint 7, a cylinder 8, Lifting bracket 9, honeycomb 10, magnetic holding platform 11, thin steel plate 12, nut 13, roller chain 14, transmission shaft 15, sprocket 16, first channel steel 17, first guide rail 18, second guide rail 19, second Channel steel 20, second roller 21, machine tool platform 22, machine tool platform 22 is provided with fixed bracket 4, 4 air cylinders 8 and magnetic holding platform 11, fixed bracket 4 is provided with mobile compression frame 5, mobile compression frame 5 One end is provided with a stepping motor 1, and the stepping motor 1 is sequentially connected with the worm gear reducer 2, the roller chain 14, the sprocket 16, the first roller 3, and the drive shaft 15, and the first roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com