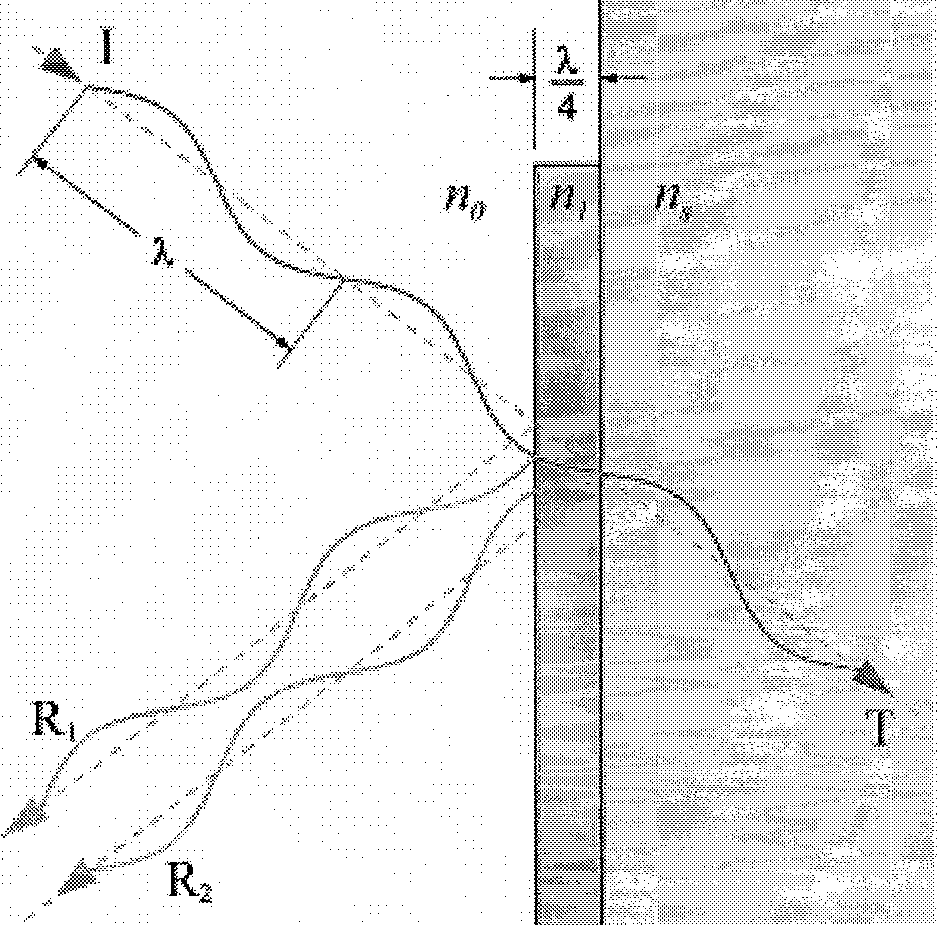

Organic/inorganic hybrid nanometer porous anti-reflection coating

An anti-reflection coating and nanoporous technology, applied in coatings, optics, instruments, etc., can solve problems such as poor mechanical properties and unstable optical properties, and achieve the effects of easy film thickness, excellent mechanical properties, and solving adhesion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

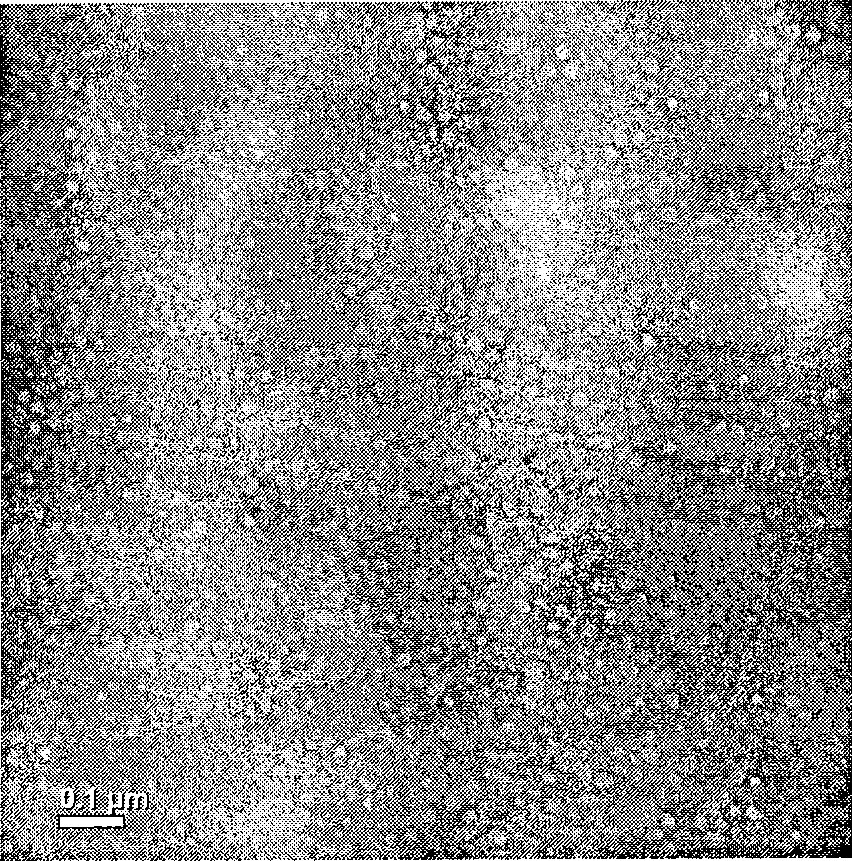

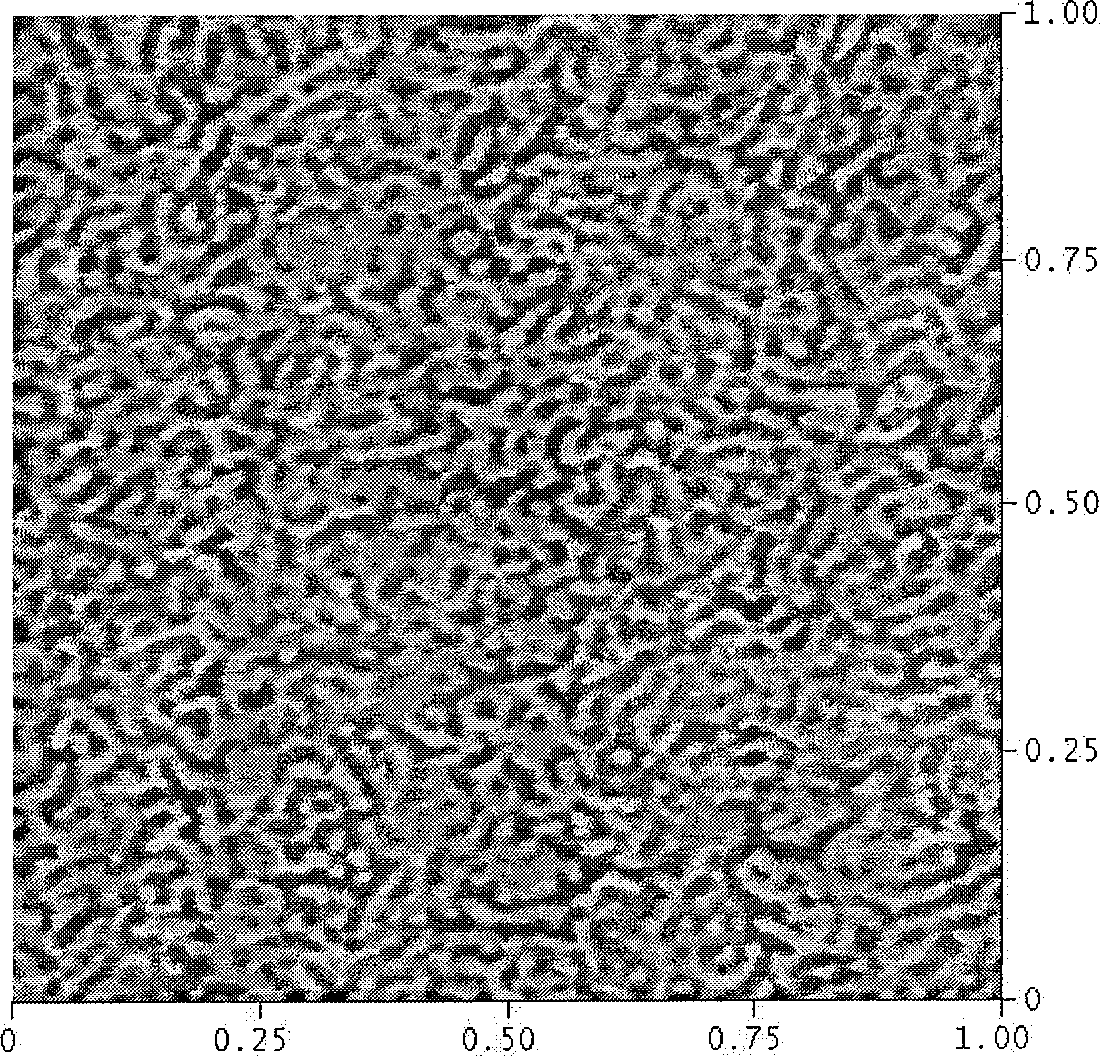

Embodiment 1

[0025] Make poly(methyl methacrylate-b-methacryloxypropyltriethylsilane) into 5% tetrahydrofuran solution, add 0.1g ethyl orthosilicate, and then use KW-4A desktop homogenizer Spin-coat the surface of the glass slide to form a nano-scale film. The speed of the first stage of homogenization is controlled at 1000r / min for 15s, and the speed of the second stage of homogenization is controlled at 3000r / min for 60s. After smearing, place the film in a saturated atmosphere of tetrahydrofuran, solvent anneal for 4 days, then place the film in a vacuum oven at 90°C for 36 hours, and immediately cool it with ice cubes after the annealing time is over. After cooling, place it in an atmosphere of ammonia water for 24 hours, then dry it naturally for 3 days, and then put it in a vacuum oven at 50° C. for 5 days. Then take it out and place it under the ultraviolet lamp of UV-40w for 5 hours. The various property parameters of the organic / inorganic hybrid nanoporous anti-reflection coating...

Embodiment 2

[0029] Make poly(methyl methacrylate-b-methacryloxypropyltriethylsilane) into 5% tetrahydrofuran solution, add 0.05g ethyl orthosilicate, and then use KW-4A desktop homogenizer Spin-coat the surface of the glass slide to form a nano-scale film. The speed of the first stage of homogenization is controlled at 1000r / min for 15s, and the speed of the second stage of homogenization is controlled at 3000r / min for 60s. After smearing, place the film in a saturated atmosphere of tetrahydrofuran, solvent anneal for 4 days, then place the film in a vacuum oven at 90°C for 36 hours, and immediately cool it with ice cubes after the annealing time is over. After cooling, place it in an atmosphere of ammonia water for 24 hours, then dry it naturally for 3 days, and then put it in a vacuum oven at 50° C. for 5 days. Then take it out and place it under the ultraviolet lamp of UV-40w for 5 hours.

Embodiment 3

[0031] Methyl acrylate-b-methacryloxypropyl triethylsilane) was made into 10% tetrahydrofuran solution, and then spin-coated into a nano-scale film on the surface of a glass slide with a KW-4A desktop glue homogenizer, and the glue was evenly coated. In the first stage, the speed is controlled at 1000r / min, and the time is 15s. In the second stage, the speed of the uniform glue is controlled at 3000r / min, and the time is 60s. After smearing, place the film in a saturated atmosphere of tetrahydrofuran, solvent anneal for 4 days, then place the film in a vacuum oven at 90°C for 36 hours, and immediately cool it with ice cubes after the annealing time is over. After cooling, place it in an atmosphere of ammonia water for 24 hours, then dry it naturally for 3 days, and then put it in a vacuum oven at 50° C. for 5 days. Then take it out and place it under the ultraviolet lamp of UV-40w for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com