Multi-mode programmable modulated arc ion plating apparatus controlled by rotary lateral magnetic field

An arc ion plating and transverse magnetic field technology, which is applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve the problems of discharge that cannot effectively improve arc spot, poor adjustability, fixed magnetic field potential, etc. Intensity is difficult to mediate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] An important feature of arc ion plating is that the arc spot discharge forms a high temperature area near it, and it will radiate to other places in the vacuum chamber at the same time, and the space of the vacuum chamber is limited, and the space around the target is also limited, so the arc source When designing, it will be difficult to break through if the thinking is limited to the limited space in the vacuum chamber. Especially for the design of the rotating magnetic field that controls the movement of the arc spot, if the rotating magnetic field generator is placed around the target in the vacuum chamber, it will involve limitations in size, material, etc. Although better results can be achieved when conditions permit, but For industrial production that requires large-area deposition and long-term work, it will be limited. In the face of wider and simpler applications, new innovations and breakthroughs are required.

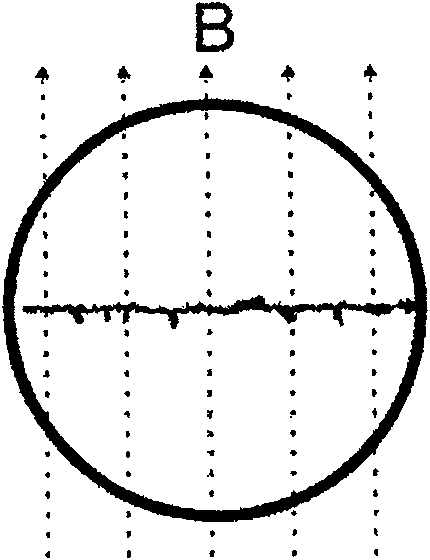

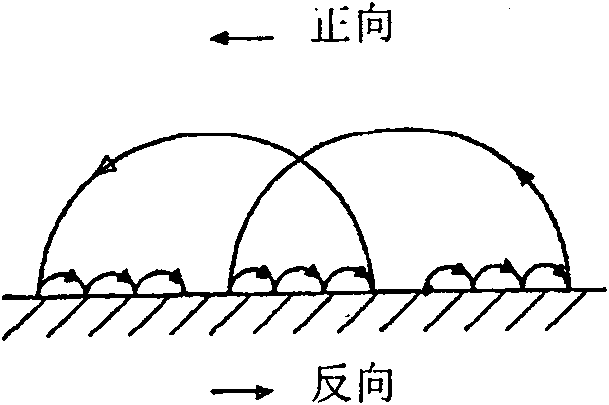

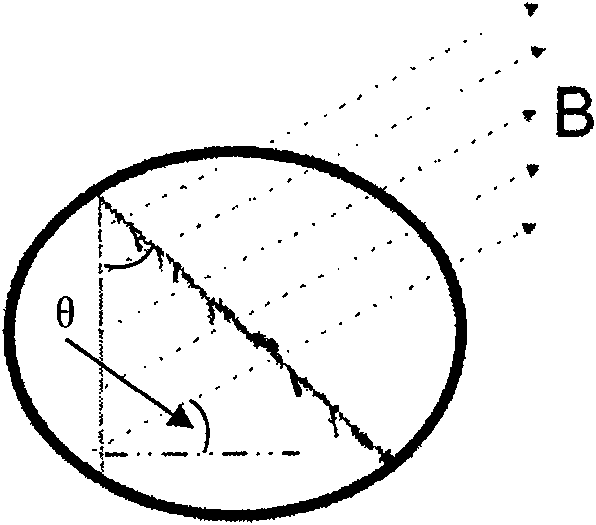

[0078] Figure 3(a)-3(c) It is a schematic d...

Embodiment 2

[0087] Since arc ion plating mainly depends on the discharge of cathode spots on the target surface to deposit the required film, it is a point source, so there is the problem of uneven distribution of plasma in the transmission space, resulting in uneven film deposition. Embodiment 2 is the same as Embodiment 1, except that a focusing magnetic field is applied near the back of the substrate clamp to improve the distribution of plasma in the transmission space, increase the density of ions at the substrate, and increase the deposition rate and deposition uniformity. Figure 5 It is the schematic diagram of the arc ion plating deposition equipment controlled by the rotating magnetic field in embodiment 2. The specific structure is as follows:

[0088] Arc ion plating deposition equipment mainly includes target material 2, rotating magnetic field device 6, water outlet pipe 9, arc pilot coil 10, water outlet 11, water inlet 12, electromagnetic coil 13, nickel-plated pure iron 14...

Embodiment 3

[0092] The difference with embodiment 1 or 2 is:

[0093] Figure 7(a)-Figure 7(b) It is the schematic diagram of the arc ion plating arc source controlled by the rotating magnetic field of embodiment 3. Among them, FIG. 7( a ) is a schematic diagram of the rotating magnetic field generator 6 . Embodiment 3 is a rotating magnetic field generator controlled by two-phase electricity. Four magnetic poles 4 are evenly distributed on the circular closed main magnetic conduction channel to form an integral electromagnetic circuit skeleton. The shape of the magnetic poles is square or circular, and the size According to the size of the space between the main magnetic channel and the target material 2, the material of the skeleton is made of high magnetic permeability material (electrical pure iron or superimposed punched silicon steel sheet). The top end of the magnetic pole 4 is straight or arc-shaped, symmetrically pointing to the center of the surface of the target 2 . FIG. 7( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com