Electrostatic spinning device for preparing directional arrangement nano fiber

A nanofiber and electrospinning technology, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of reduced application value and achieve good repeatability, good order and simple process.

Inactive Publication Date: 2009-02-11

CHONGQING UNIV

View PDF0 Cites 47 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the collection device is a static flat plate, the obtained nanofibers must be disorderly arranged, and the application value of this disorderly arranged nanofibers is greatly reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0027] 2. Preparation of PAN (polyacrylonitrile) oriented fibers.

[0028] Dissolve PAN in dimethylformamide at a concentration of 7-15% (w / v%), select a concentration of 12% (w / v%) during implementation, stir with a magnetic stirrer for 12 hours, pour into a syringe and spin Silk, the spinning voltage range is 10-35kV.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

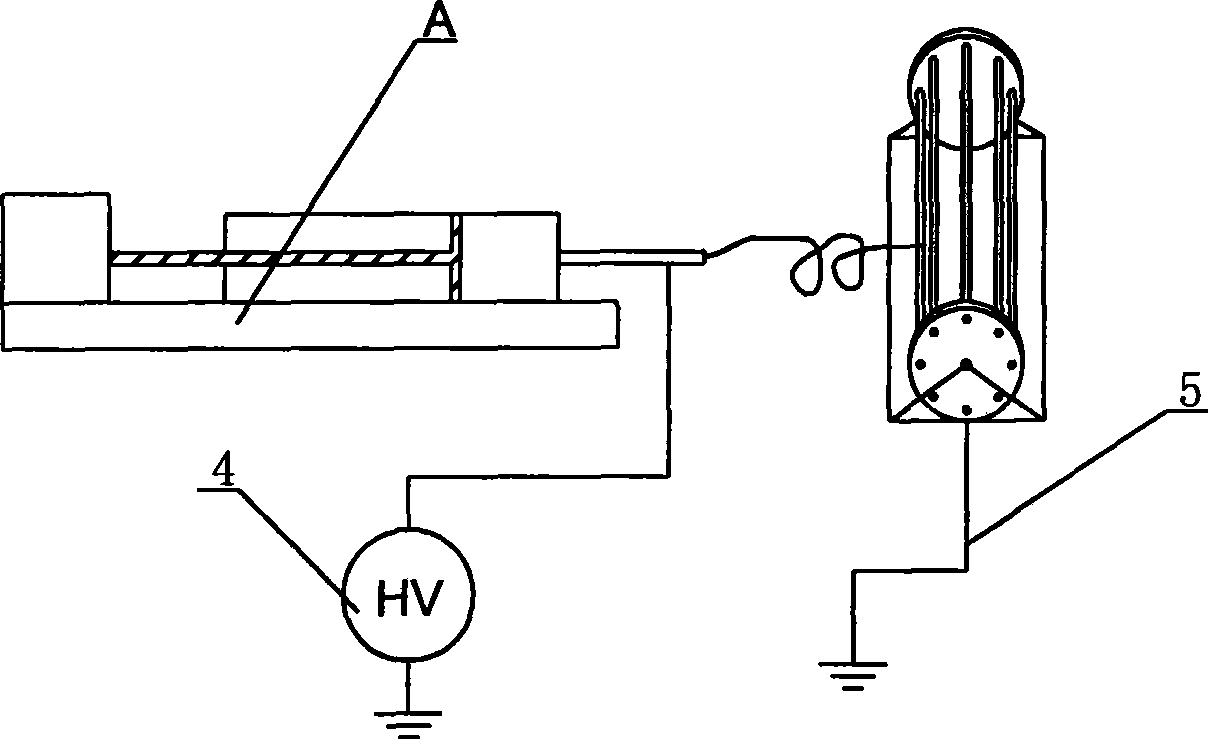

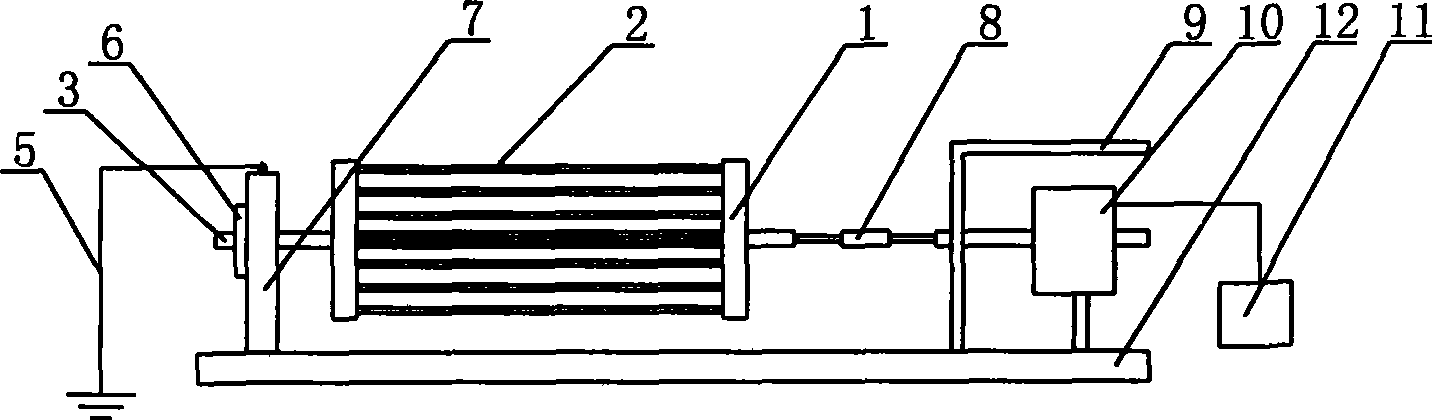

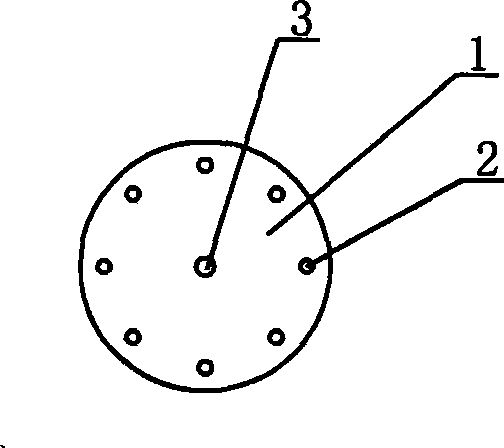

The invention relates to an electrostatic spinning device which is used for preparing direction arrangement nanofibers. The device comprises a high voltage source, an injector, an ejector jet pump which pushes the injector and a gathering unit, wherein, the high voltage source which is connected with the position of an injector pinhead is anode; the gathering unit which is ground connection by an earth wire is cathode; the device is characterized in that the gathering unit is an open fiber gathering device which consists of two parts of a performance element and a control unit; wherein, the performance element is an open roller which is formed by a centre pivot and a copper pipe which is parallel to the centre pivot, the two ends of the copper pipes are fixed on the periphery of an aluminum subpanel; the roller has a copper centre pivot; the control unit comprises a driving motor and a rotary speed controller; the motor drives the roller to rotate by a shaft joint; the motor shields the disturbance of electric field by a shield cover; the rotary speed controller controls the rotate speed of the motor, and the rotate speed is 800-1000rpm; the performance element and the control unit are all supported by a PVP plate. The produced nanofibre has the advantages of good order and thick film, and is suitable for biomedicine support materials.

Description

technical field [0001] The invention relates to an electrospinning technology for aligning nanofibers, and is an electrospinning device for preparing aligned nanofibers. Background technique [0002] Electrospinning is a technology in which polymer solution or melt is sprayed and stretched under electrostatic action to obtain nanoscale fibers, that is, DC high voltage is applied between the polymer solution or melt and the collection device to make the polymer solution or melt The body is charged with thousands to tens of thousands of volts of high-voltage static electricity. When the electric field force is strong enough, the charged polymer droplets overcome the surface tension to form a jet stream. The thin stream solidifies with the evaporation of the solvent during the spraying process, and finally falls on the collecting device to form a fiber mat similar to a non-woven fabric, and its nanofiber diameter is generally between tens of nanometers and several microns. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01D5/00

Inventor 杨力李贤李林昊李海滨王平蒋稼欢

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com