P type silicon carbide device and preparation thereof

A production method and technology of silicon carbide, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as difficult to determine, difficult to high doping, limited doping concentration, etc., and achieve good ohmic contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

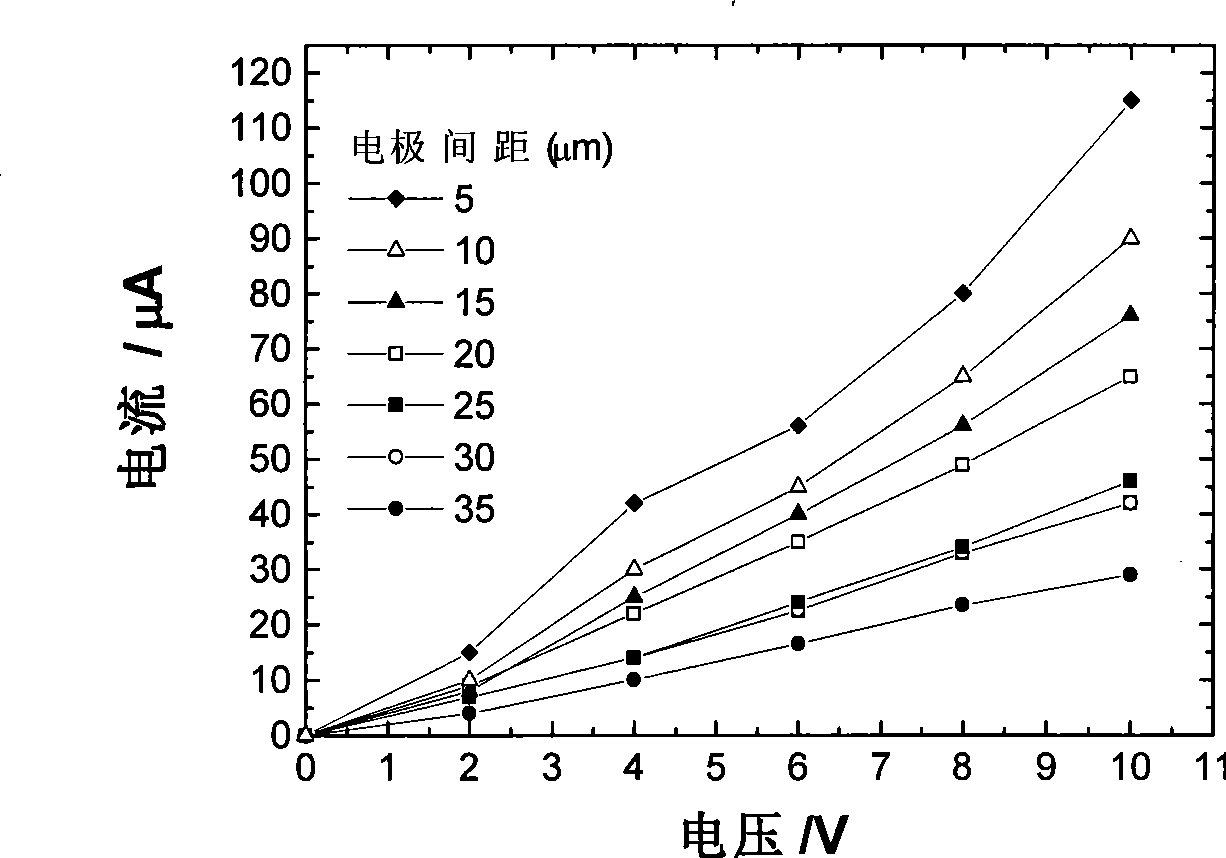

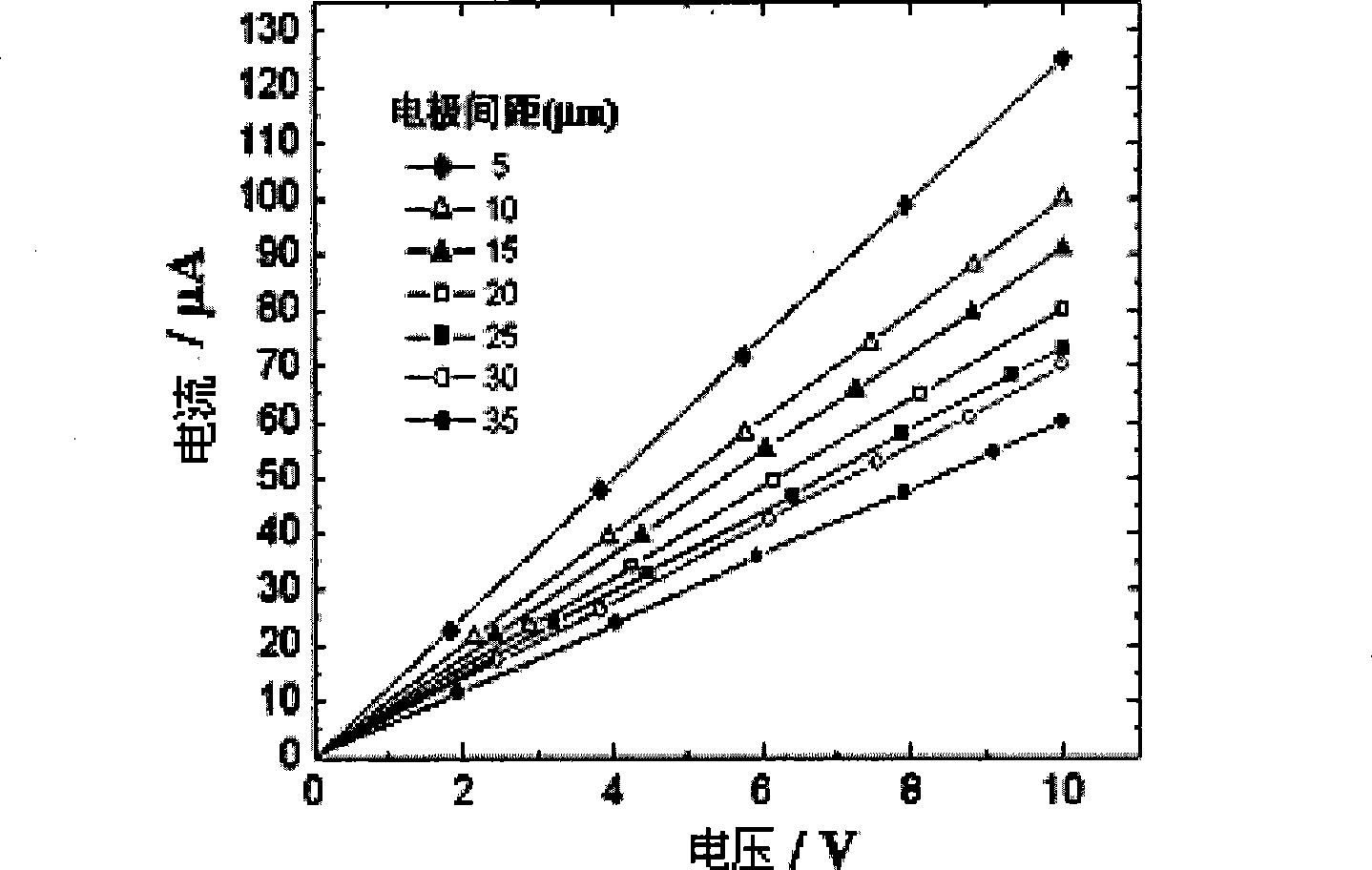

[0014] A preferred embodiment of the P-type silicon carbide device of the present invention includes a silicon carbide layer and an aluminum electrode layer, and a gold nanoparticle layer is arranged between the silicon carbide layer and the aluminum electrode layer. The thickness of the gold nanoparticle layer is 90-110 nanometers, and may be 90, 100, or 110 nanometers. The thickness of the aluminum electrode layer is about 2 microns.

[0015] The manufacturing method of the above-mentioned P-type silicon carbide device of the present invention comprises

[0016] First, a gold nanoparticle layer is deposited on the silicon carbide layer and annealed. The gold nanoparticle layer is deposited on the silicon carbide layer by sputtering. The thickness of the gold nanoparticle layer is estimated to be 100nm. The annealing temperature is 450-710° C., and the annealing time is 8-10 minutes. The protective gas used in the annealing process is nitrogen.

[0017] Three specific embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com