Organic opto-electronic device with protection layer and preparation method thereof

A technology for optoelectronic devices and protective layers, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of OLED stability and lifespan, and achieve improved surface properties, improved flatness, and novel structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

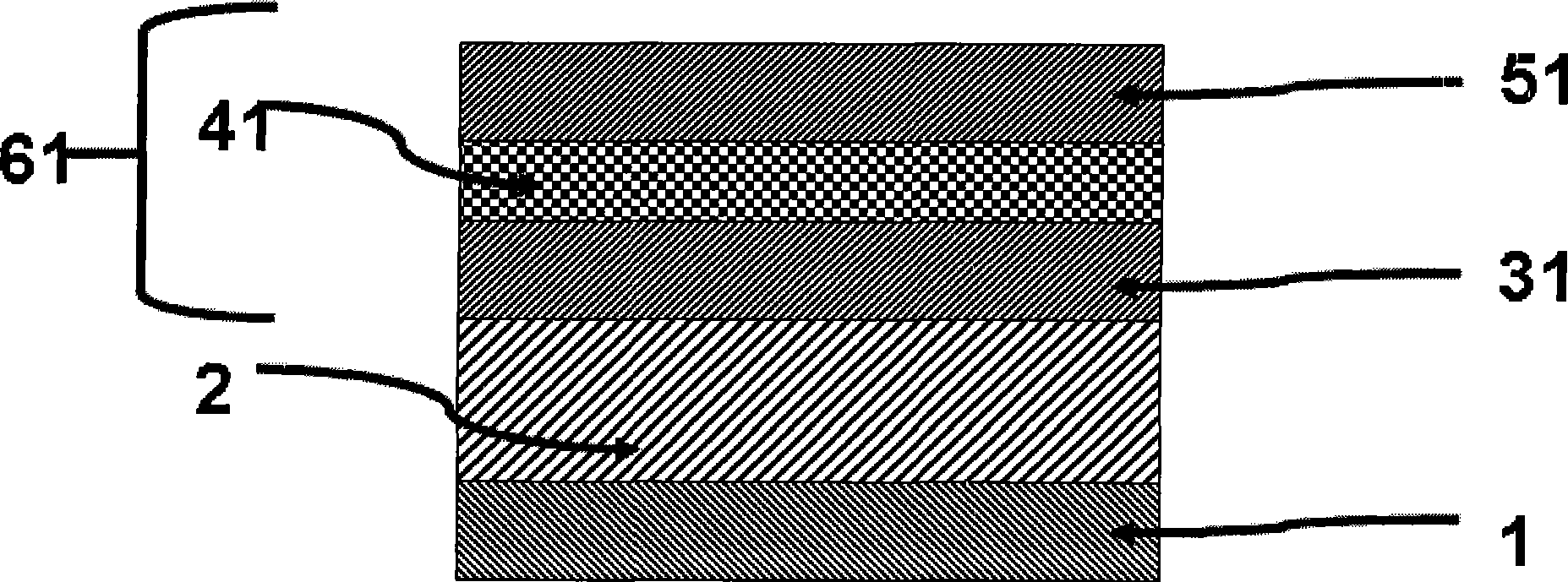

[0058] Such as figure 1 As shown, the substrate 1 in the structure of the device, the organic optoelectronic device 2 is an organic electroluminescent device, an organic material layer 31 , a hydrophilic material layer 41 , an organic material layer 51 , and a combination layer 61 .

[0059] The substrate 1 of the device is PET, the organic optoelectronic device 2 is an organic electroluminescent device, the organic material layer 31 is UV glue, the hydrophilic material layer 41 is calcium oxide, and the organic material layer 51 is UV glue.

[0060] The preparation method is as follows:

[0061] ① Prepare an organic material layer UV glue 300nm on the upper layer of the organic electroluminescent device;

[0062] ② Evaporate or spin-coat a layer of calcium oxide 500nm on the above-mentioned organic material layer UV glue;

[0063] ③ Deposit a layer of organic material layer UV glue 300nm on the above-mentioned hydrophilic material layer calcium oxide;

[0064] ④ Repeat the...

Embodiment 2

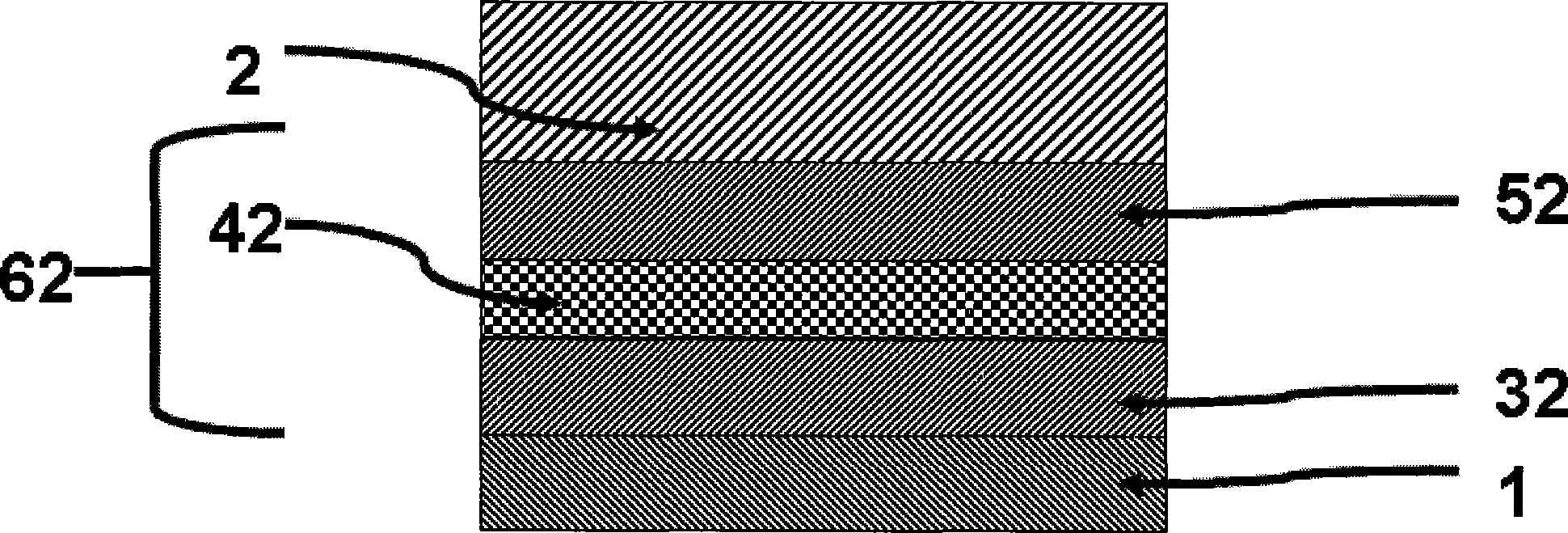

[0066] Such as figure 2 As shown, the substrate 1 in the structure of the device, the organic optoelectronic device 2 is an organic electroluminescent device, an organic material layer 32 , a hydrophilic material layer 42 , an organic material layer 52 , and a combination layer 62 .

[0067] The substrate 1 of the device is PET, the organic optoelectronic device 2 is an organic electroluminescent device, the organic material layer 32 is UV glue, the hydrophilic material layer 42 is calcium oxide, and the organic material layer 52 is UV glue.

[0068] The fabrication process of the device is as follows:

[0069] ① Prepare an organic material layer UV glue 300nm on the upper layer of the substrate;

[0070] ② Prepare a layer of hydrophilic material layer calcium oxide 500nm on the above organic material layer UV glue;

[0071] ③ Deposit a layer of organic material layer UV glue 300nm on the above-mentioned hydrophilic material layer calcium oxide;

[0072] ④Repeat the above ...

Embodiment 3

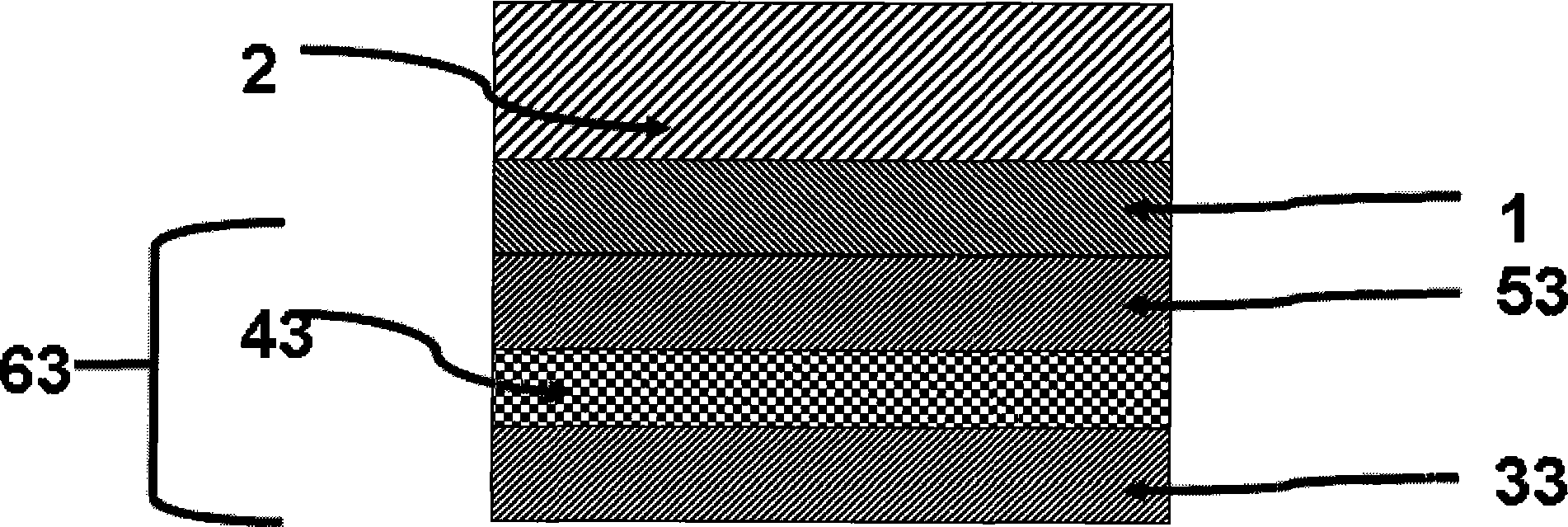

[0075] Such as image 3 As shown, the substrate 1 in the structure of the device, the organic optoelectronic device 2 is an organic thin film transistor, an organic material layer 33 , a hydrophilic material layer 43 , an organic material layer 53 , and a combination layer 63 .

[0076] The substrate 1 of the device is PET, the organic optoelectronic device 2 is an organic thin film transistor, the organic material layer 33 is UV glue, the hydrophilic material layer 43 is calcium oxide, and the organic material layer 53 is UV glue.

[0077] The fabrication process of the device is similar to that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com