Bitter earth nano-catalyst material capable of being used for high-energy solid propellant and synthetic method thereof

A nano-catalyst, solid propellant technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve incomplete combustion, performance loss, complex equipment, etc. problem, to achieve the effect of low cost, good catalytic activity, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

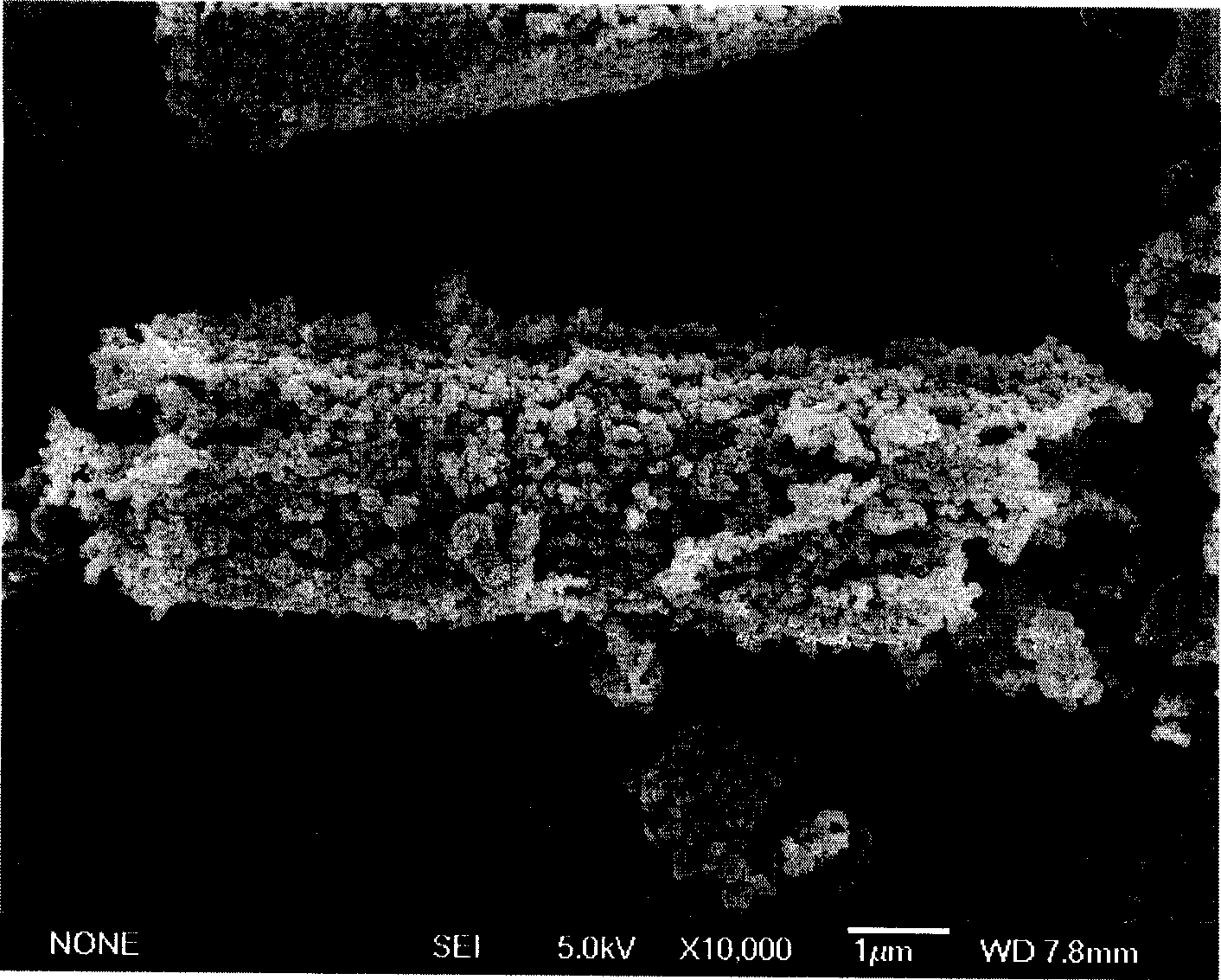

[0012] Example 1: 4.29g (0.02mol) of analytically pure magnesium acetate with 4 crystal waters was added to 150mL of absolute ethanol, stirred and dissolved to obtain a transparent solution. Then transfer the obtained solution into a reaction kettle, seal it, place it in a constant temperature box, and keep it warm at 160°C for 6 hours. After the reaction, the reaction kettle is naturally cooled to room temperature, filtered, dried, and collected to obtain a white precursor sample. The precursor was placed in a muffle furnace and calcined at 450 °C for 2 h to obtain a white MgO nanocatalyst.

example 2

[0013] Example 2: Add 4.29g (0.02mol) of analytically pure magnesium acetate with 4 crystal waters into 150mL of absolute ethanol, stir and dissolve to obtain a transparent solution. Then the obtained solution was transferred into a reaction kettle, sealed, placed in a constant temperature box, and kept at 180°C for 6 hours. After the reaction, the reaction kettle was naturally cooled to room temperature, filtered, dried, and collected to obtain a white precursor sample. The precursor was placed in a muffle furnace and calcined at 450 °C for 2 h to obtain a white MgO nanocatalyst.

example 3

[0014] Example 3: Accurately weigh 0.098g ammonium perchlorate and 0.002g MgO nanometer catalyst on an electronic balance. The two are fully ground and mixed with a mortar to obtain ammonium perchlorate (content: 2%) added with MgO nanometer catalyst. Take 15 mg of pure ammonium perchlorate or ammonium perchlorate added with MgO nano-catalyst, put it in a differential scanning calorimeter for analysis, and compare and study the catalytic effect of MgO nano-catalyst on the thermal decomposition of ammonium perchlorate.

PUM

| Property | Measurement | Unit |

|---|---|---|

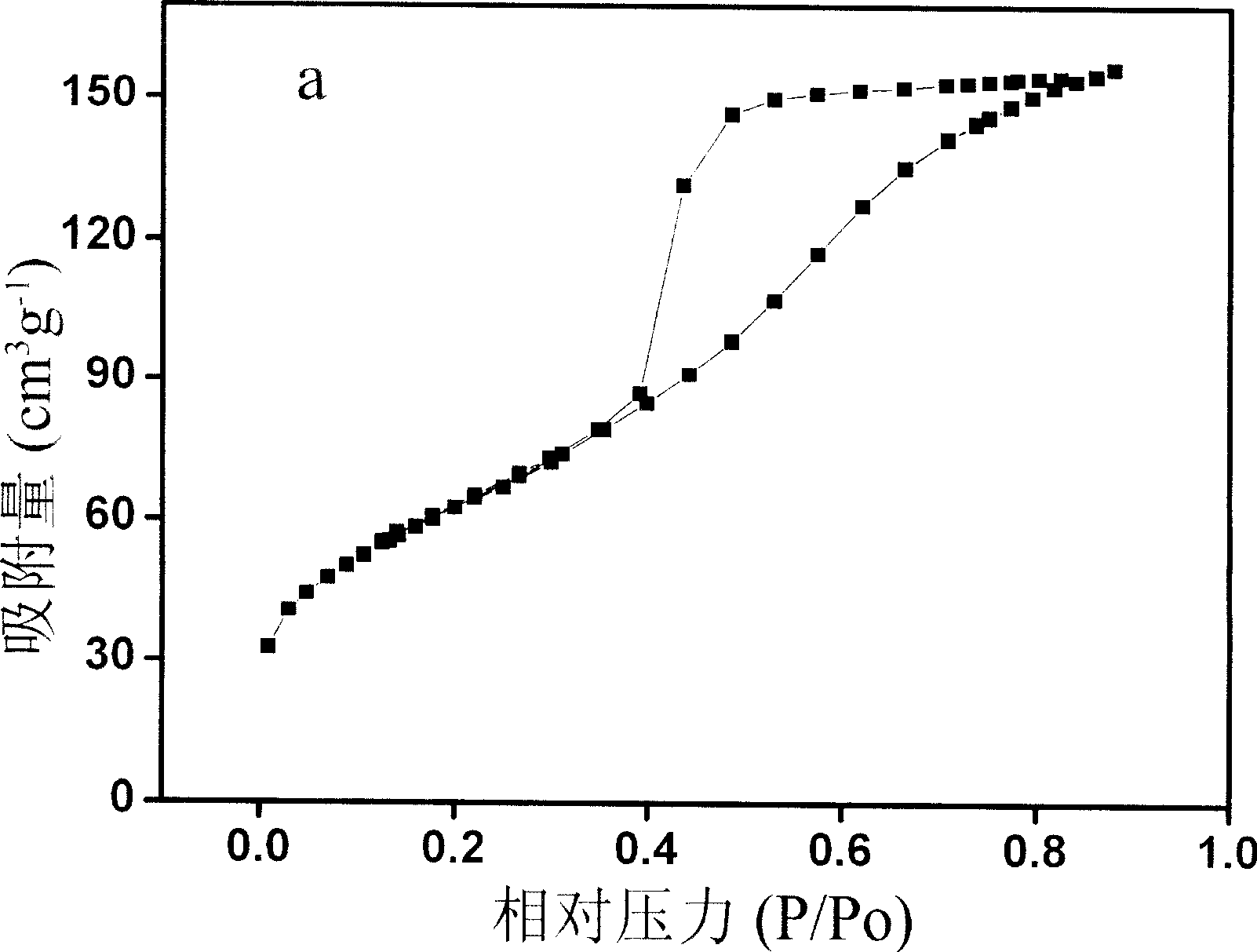

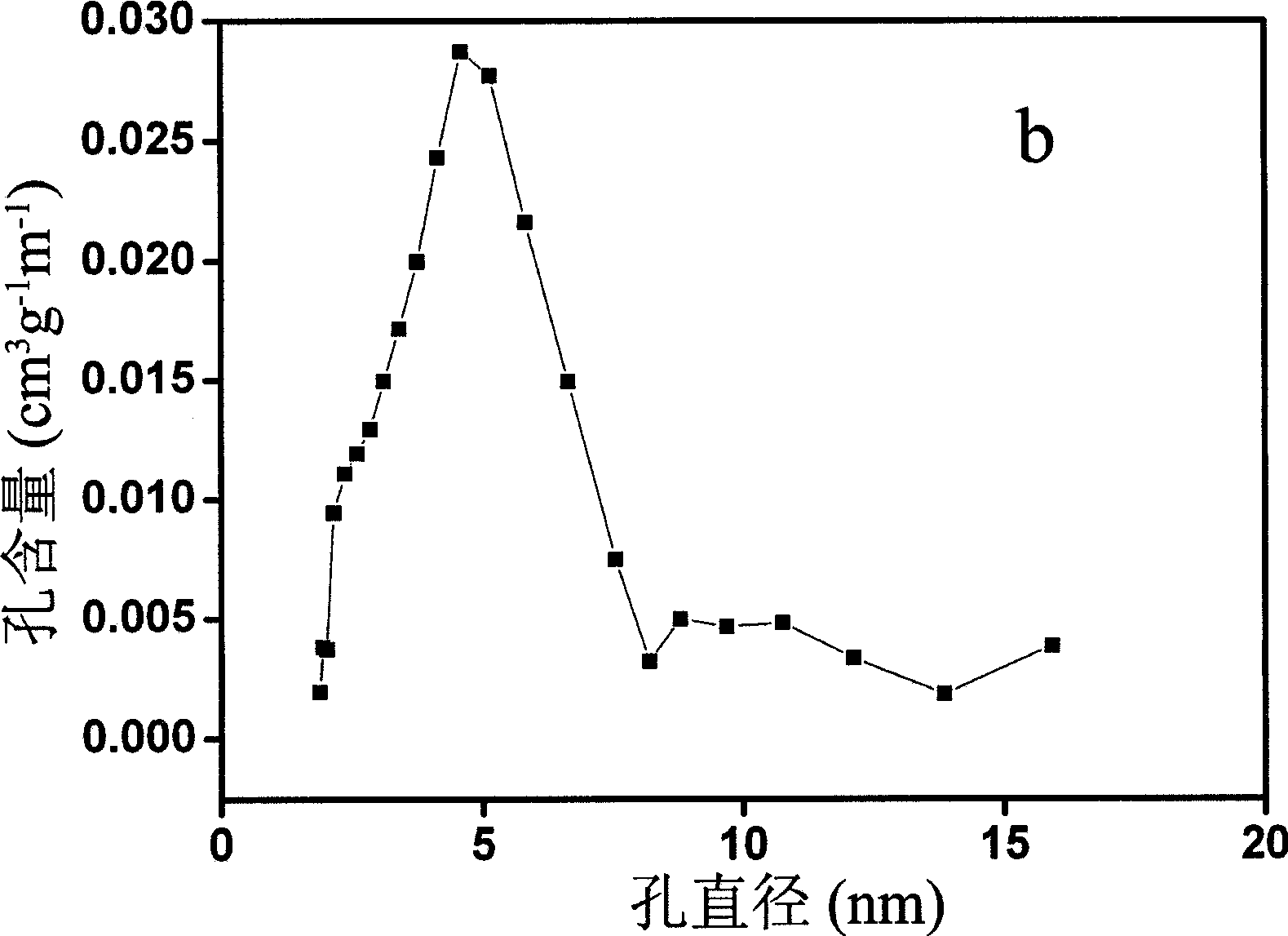

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com