High-early strength type polycarboxylic acids dehydragent and preparation technique thereof

A technology of polycarboxylic acid series and preparation process, which is applied in the field of early-strength polycarboxylate series water reducer and its preparation process, can solve the problems of inability to obtain water reducing rate, slow strength development, long reaction time, etc., and achieve remarkable Enhance the effect early, improve the construction progress, and speed up the effect of formwork turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. The composition and ratio of the monomers used are as follows:

[0031] 1) Monomer A: acrylic acid, accounting for 10% of the total monomer weight;

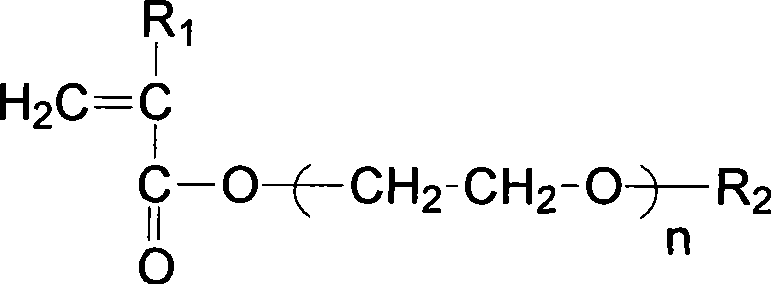

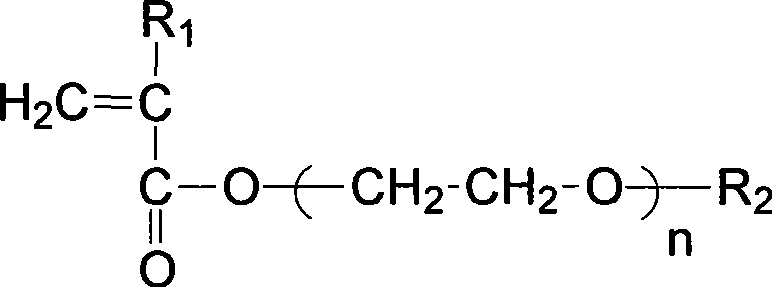

[0032] 2) Monomer B: its general structural formula is as follows

[0033]

[0034] R in the general formula 1 is a hydrogen atom, R 2 It is a methyl group; wherein n=20 monomer B accounts for 50% of the total monomer weight, and n=60 monomer B accounts for 35% of the total monomer weight;

[0035] 3) Monomer C: sodium allyl sulfonate, accounting for 3.5% of the total monomer weight;

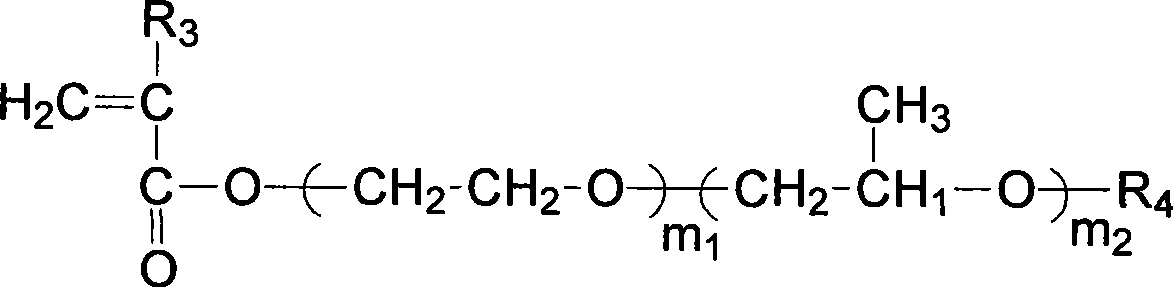

[0036] 4) Monomer D: its general structure is as follows

[0037]

[0038] R in the general formula 3 is a hydrogen atom, R 4 is methyl, m 1 =40, m 2 =6; Monomer D accounted for 1.5% of the total monomer weight.

[0039] Two, the preparation process is as follows:

[0040] 1) According to the above ratio, monomer A, monomer B, monomer C and monomer D of two different numbers of chain members are added to the reaction kettl...

Embodiment 2

[0044] 1. The composition and ratio of the monomers used are as follows:

[0045] 1) Monomer A: acrylic acid, accounting for 7% of the total monomer weight;

[0046] 2) Monomer B: its general structural formula is as follows

[0047]

[0048] R in the general formula 1 is a hydrogen atom, R 2 It is a methyl group; wherein n=25 monomer B accounts for 45% of the total monomer weight, and n=50 monomer B accounts for 40% of the total monomer weight;

[0049] 3) Monomer C: sodium allyl sulfonate, accounting for 5.5% of the total monomer weight;

[0050] 4) Monomer D: its general structure is as follows

[0051]

[0052] R in the general formula 3 is a hydrogen atom, R 4 is methyl, m 1 =30, m 2 =3; Monomer D accounts for 2.5% of the total monomer weight.

[0053] Two, the preparation process is as follows:

[0054]1) According to the above ratio, monomer A, monomer B, monomer C and monomer D of two different numbers of chain members are added to the reaction kettle a...

Embodiment 3

[0058] 1. The composition and ratio of the monomers used are as follows:

[0059] 1) Monomer A: acrylic acid, accounting for 5% of the total monomer weight;

[0060] 2) Monomer B: its general structural formula is as follows

[0061]

[0062] R in the general formula 1 is a hydrogen atom, R 2 It is a methyl group; wherein n=30 monomer B accounts for 35% of the total monomer weight, and n=40 monomer B accounts for 50% of the total monomer weight;

[0063] 3) Monomer C: sodium allyl sulfonate, accounting for 7% of the total monomer weight;

[0064] 4) Monomer D: its general structure is as follows

[0065]

[0066] R in the general formula 3 is a hydrogen atom, R 4 is methyl, m 1 =20, m 2 =10; Monomer D accounted for 3% of the total monomer weight.

[0067] Two, the preparation process is as follows:

[0068] 1) According to the above ratio, monomer A, monomer B, monomer C and monomer D of two different numbers of chain members are added to the reaction kettle at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com