Processing fluid for preparing corrosion product film / layer cross section metallographic sample and processing method thereof

A technology of corrosion products and metallographic samples, applied in the preparation of test samples, weather resistance/light resistance/corrosion resistance, coating, etc., can solve problems such as complex operation, low deposition efficiency, human body and environmental hazards, and achieve The operation process is simple, the deposition efficiency is improved, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

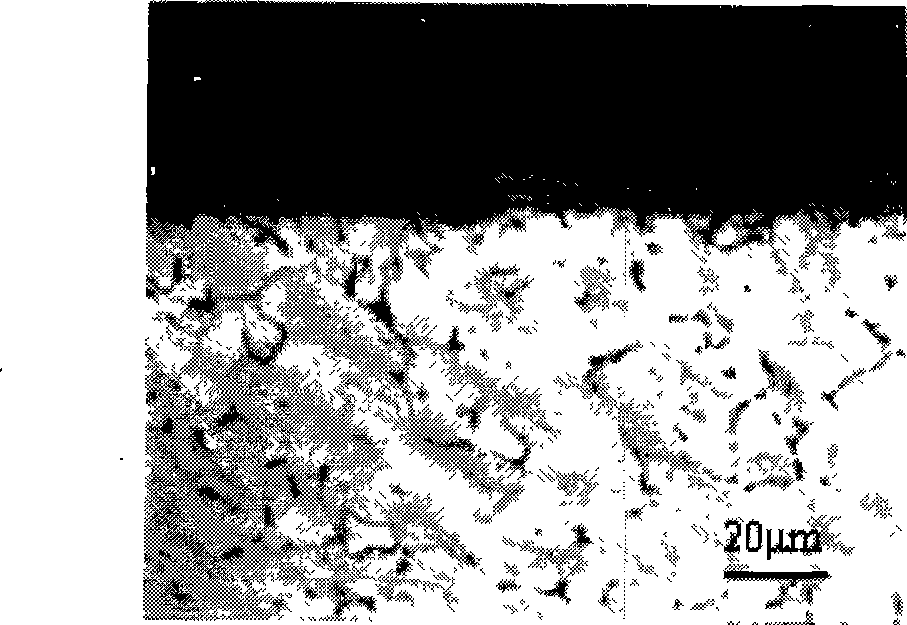

[0049] Example 1 Cross-sectional morphology of two Ti3Al-based alloys after 300 cycles of oxidation at 850°C in air

[0050] 1. Treatment solution: The chemical composition of the pretreatment solution is shown in Table 1, and the chemical composition of the electroless plating solution is shown in Table 2.

[0051] Table 1 Chemical composition of pretreatment liquid

[0052]

[0053] Table 2 Chemical composition of electroless plating solution

[0054]

[0055] Wherein, the corrosion inhibitor is boric acid, and the film-forming accelerator is sodium fluoride.

[0056] 2. Treatment method:

[0057] 1) The main process conditions and operation process of each stage of pretreatment are as follows:

[0058] a) Sensitization treatment: According to the formula shown in Table 1, pour the treatment solution into the beaker, and completely immerse the sample in the treatment solution. The sample should be shaken constantly during the whole process, but the samples should not overlap...

Embodiment 2

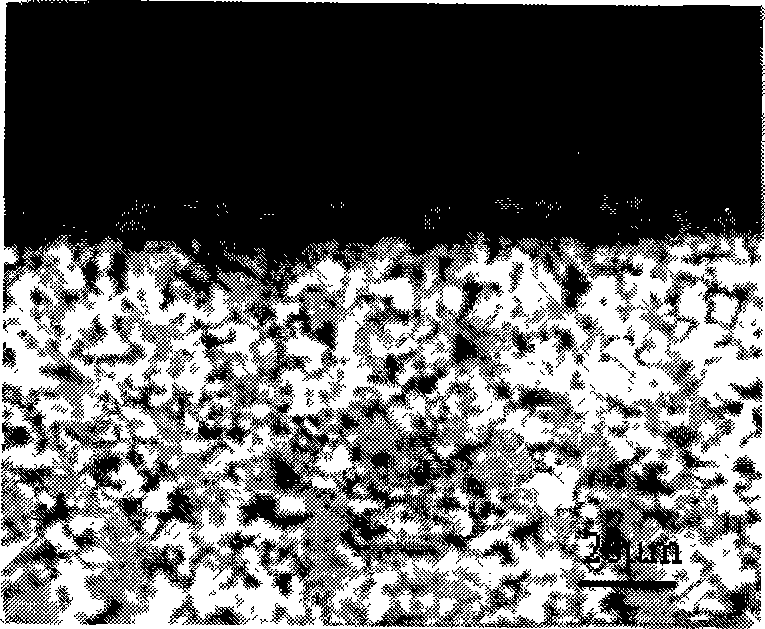

[0069] Example 2 Cross-sectional morphology of Ni20Cr alloy after cyclic oxidation at 1050℃ in air for 350 cycles

[0070] 1. Treatment solution: The chemical composition of the pretreatment solution is shown in Table 3, and the chemical composition of the electroless plating solution is shown in Table 4.

[0071] Table 3 Chemical composition of pretreatment liquid

[0072]

[0073] Table 4 Chemical composition of electroless plating solution

[0074]

[0075] Wherein, the corrosion inhibitor is boric acid, and the film forming promoter is sodium fluoride (NaF).

[0076] 2. Treatment method:

[0077] 1) The main process conditions and operation process of each stage of pretreatment are as follows:

[0078] a) Sensitization treatment: According to the formula shown in Table 3, pour the treatment solution into the beaker, and completely immerse the sample in the treatment solution. The sample should be shaken constantly during the whole process, but the samples should not overla...

Embodiment 3

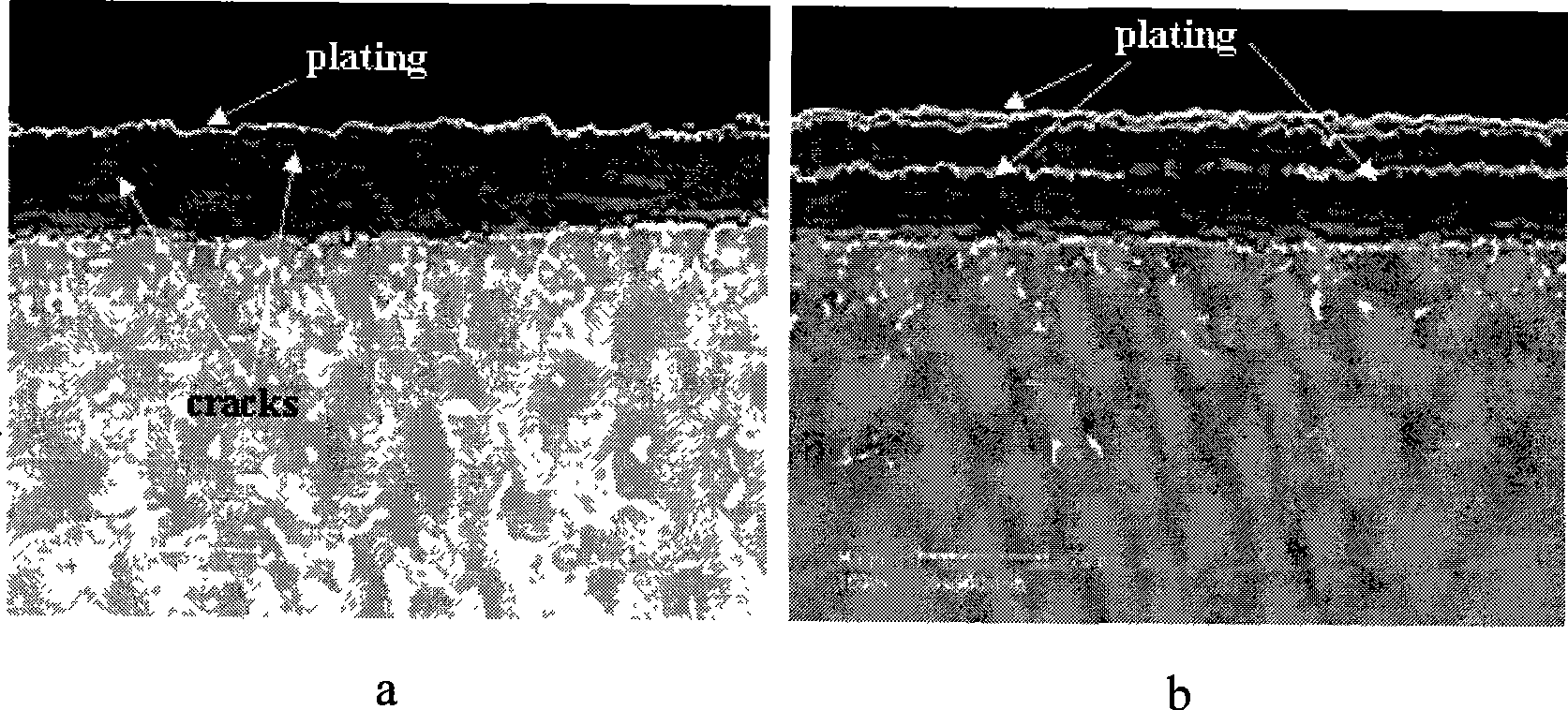

[0088] Example 3 Surface coating 3mg / cm 2 Na 2 SO 4 Cross-sectional morphology of salt film Ti-24Al-14Nb-3V-0.5Mo-0.3Si(at.pct) alloy after corrosion at 850℃ for 10h

[0089] 1. Treatment solution: the chemical composition of the pretreatment solution is shown in Table 5, and the chemical composition of the electroless plating solution is shown in Table 6.

[0090] Table 5 Chemical composition of pretreatment liquid

[0091]

[0092] Table 6 Chemical composition of electroless plating solution

[0093]

[0094] Wherein, the corrosion inhibitor is boric acid, and the film forming promoter is sodium fluoride (NaF).

[0095] 2. Treatment method:

[0096] 1) The main process conditions and operation process of each stage of pretreatment are as follows:

[0097] a) Sensitization treatment: According to the formula shown in Table 5, pour the treatment solution into a beaker, and completely immerse the sample in the treatment solution. The sample should be shaken constantly during th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com