Anisotropic etching method

An anisotropic, etching gas technology, used in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., can solve problems such as unexpected mechanical design, incomplete anisotropic contour, influence, etc., to increase practical performance, widening the surface temperature range, and simplifying the process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

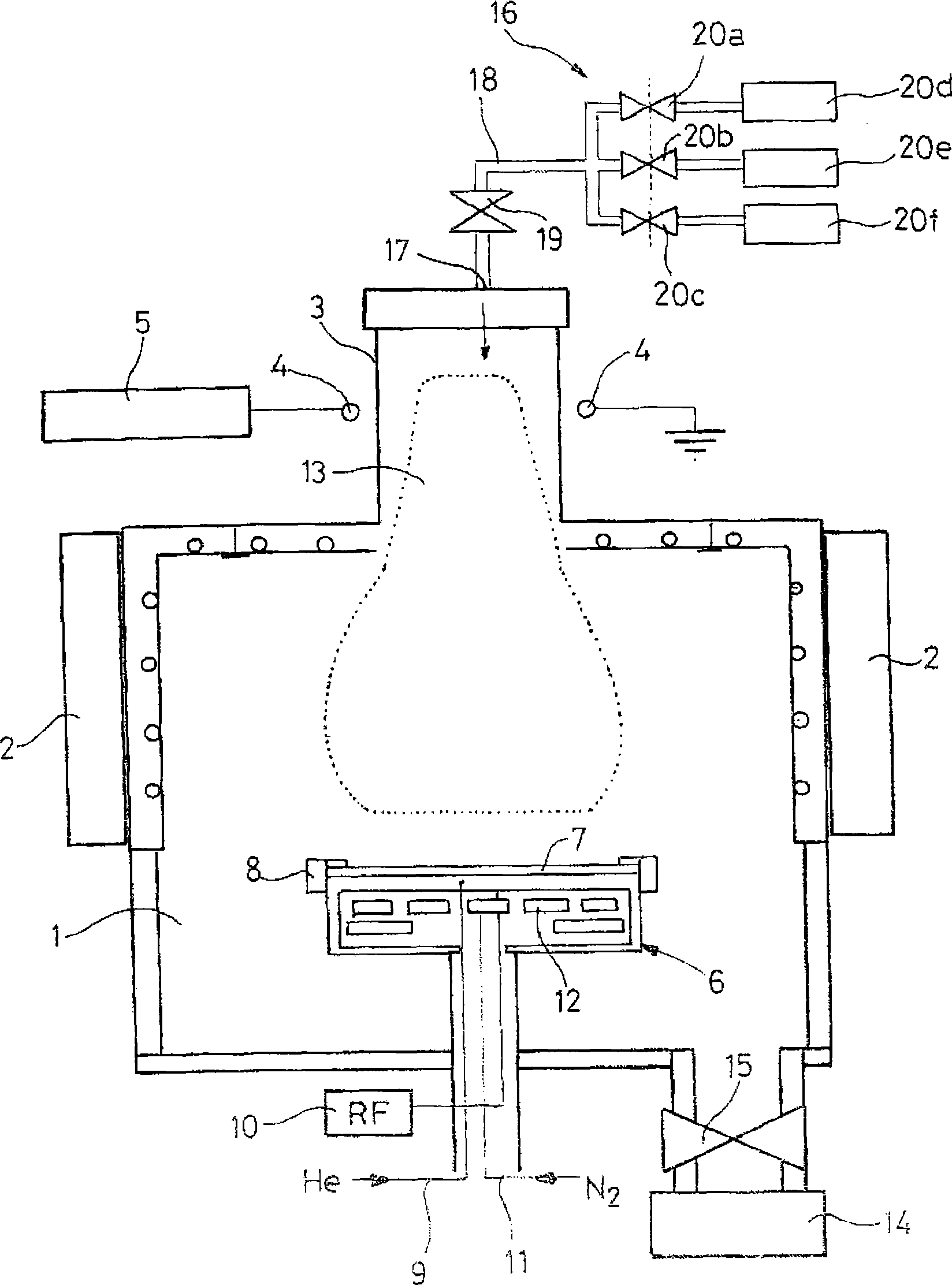

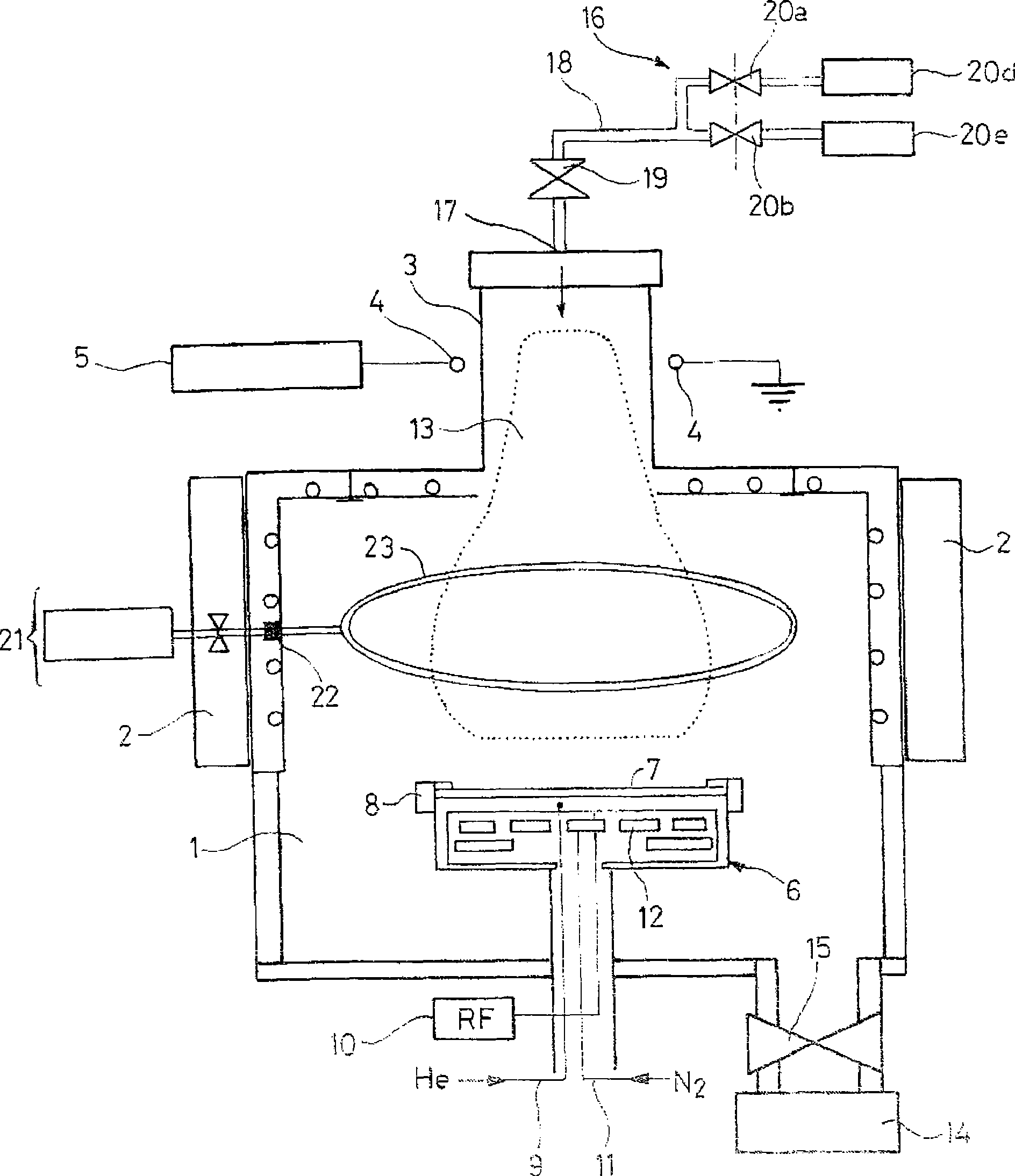

[0043] figure 1 The apparatus shown in is a plasma etcher comprising a processing chamber 1 surrounded by permanent magnets 2 arranged in multipoles to reduce electron losses at the chamber walls. The chamber 1 is in communication with a plasma source whose conduit 3 of dielectric material in which the plasma is formed is surrounded by a coupling electrode 4 to which is supplied a radio frequency (RF) alternating current generated by an RF generator 5, RF The generator 5 provides RF (13.56 MHz) power P of 500W to 2000W.

[0044] Chamber 1 houses a substrate holder 6 . The approximately 100 mm thick substrate 7 to be etched is fixed to the substrate holder 6 by mechanical or electrostatic means, here mechanically for example with a ring 8 . The substrate 7 is separated from the substrate holder 6 by a helium membrane 9 . A bias voltage U of 20V to 60V, preferably 50V is applied to the substrate 7 by means of an RF (13.56MHz) or low frequency (50-500Hz) generator 10 . By cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com