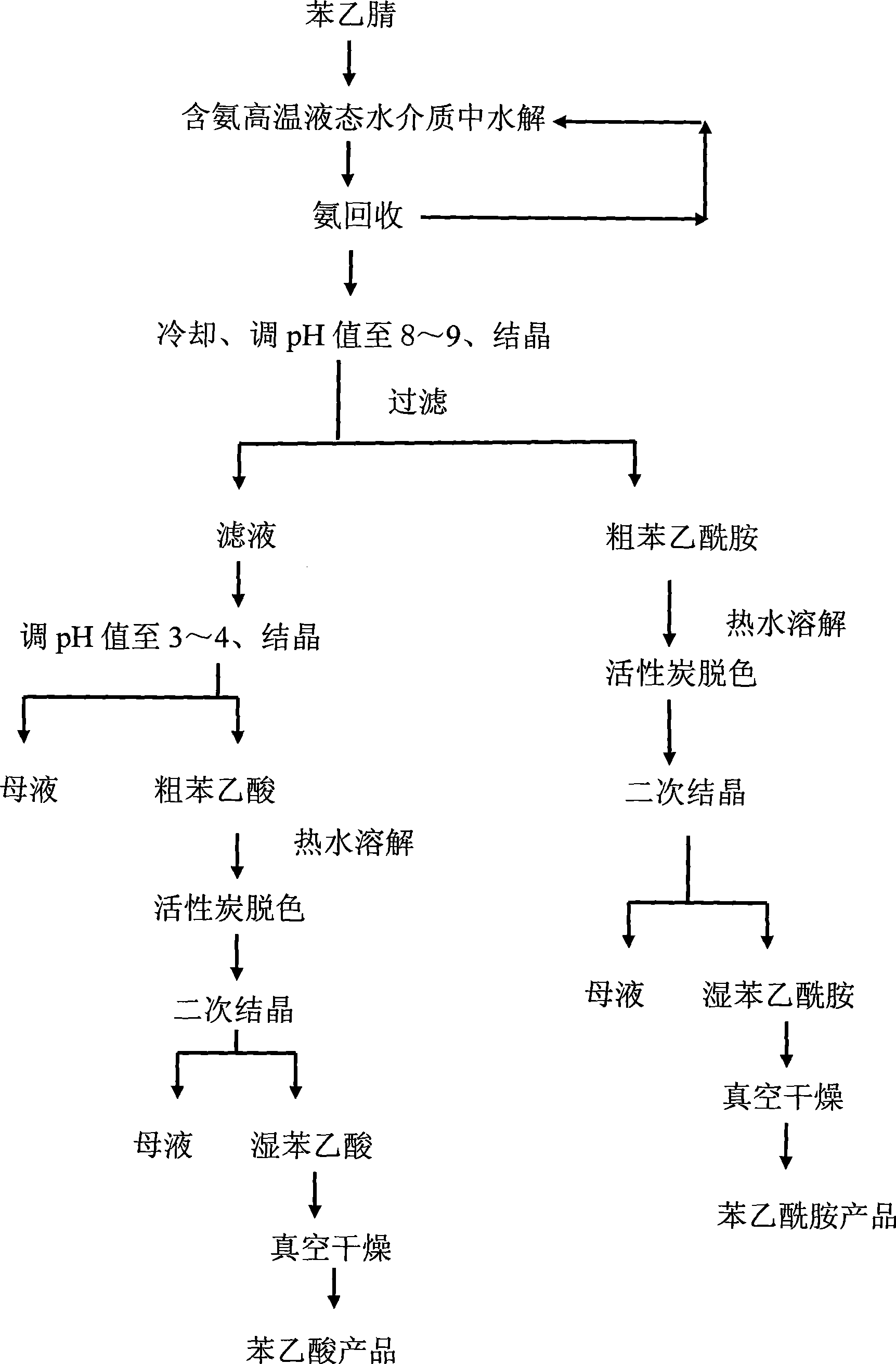

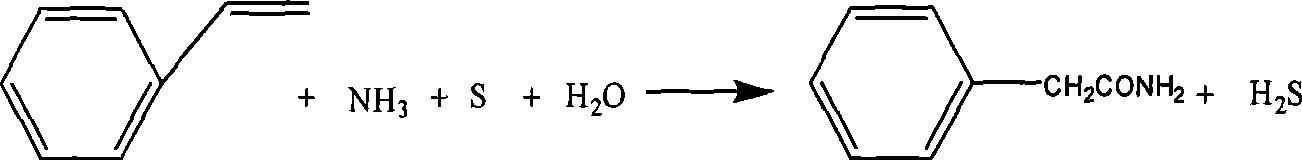

Method for simultaneously preparing phenylacetamide and phenylacetic acid by benzyl cyanide hydrolysis in ammonia-containing high temperature aqueous water medium

A high-temperature liquid water and phenylacetamide technology, which is applied in the direction of nitrile preparation, chemical instruments and methods, and carboxylic acid amide preparation, can solve the problems of high reaction temperature, weak catalytic ability, and low yield of phenylacetamide, and achieve a reduction Effects of reaction temperature, increased reaction speed, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 360g of deionized water and 45g of phenylacetonitrile (mass ratio of deionized water to phenylacetonitrile is 8) into a 500mL intermittent autoclave, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 2 minutes, and use water vapor Take away the oxygen in the kettle; inject ammonia water with a concentration of 25% by weight through a metering pump, so that the ammonia concentration in the reactant in the kettle is 4g / L, continue to heat up to 180°C for 120min; after the hydrolysis, cool down to 100°C, open The exhaust valve recovers the ammonia gas in the kettle, and the ammonia gas is absorbed by water to make ammonia water and reused in step 2; the hydrolyzate is cooled, added with NaOH solution to adjust the pH value to 8-9, crystallized, and filtered to obtain crude phenylacetamide; Phenylacetamide obtains 25.0g phenylacetamide product after activated carbon decolorization, secondary crystallization, vacuum drying, and product i...

Embodiment 2

[0043] Add 350g of deionized water and 50g of phenylacetonitrile (mass ratio of deionized water to phenylacetonitrile is 7) into a 500mL intermittent autoclave, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 3 minutes, and use water vapor Take away the oxygen in the kettle; inject ammonia water with a concentration of 25% by weight through a metering pump, so that the ammonia concentration in the reactant in the kettle is 3g / L, continue to heat up to 190°C for 90 minutes; after the hydrolysis is completed, cool down to 100°C, open The exhaust valve reclaims the ammonia in the kettle, and the ammonia is absorbed by water to make ammonia water and reused in step 2; the hydrolyzate is cooled and added with Na 2 CO 3 Adjust the pH value of the solution to 8-9, crystallize, and filter to obtain crude phenylacetamide; the crude phenylacetamide is decolorized by activated carbon, recrystallized, and vacuum-dried to obtain 27.0g of phenylacetamide...

Embodiment 3

[0045] Add 360g of deionized water and 60g of phenylacetonitrile (the mass ratio of deionized water to phenylacetonitrile is 6) into a 500mL intermittent autoclave, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 4 minutes, and use water vapor Take away the oxygen in the kettle; inject ammonia water with a concentration of 25% by weight through a metering pump, so that the ammonia concentration in the reactant in the kettle is 2g / L, continue to heat up to 200°C for 40min; after the hydrolysis, cool down to 100°C, open The exhaust valve recovers the ammonia gas in the kettle, and the ammonia gas is absorbed by water to make ammonia water and reused in step 2; the hydrolyzate is cooled and added with NaHCO 3 Adjust the pH value of the solution to 8-9, crystallize, and filter to obtain crude phenylacetamide; the crude phenylacetamide is decolorized by activated carbon, recrystallized, and vacuum-dried to obtain 37.9g of phenylacetamide produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com