Nano modified WC/Co cemented carbide material and manufacturing method thereof

A nano-modified material and cemented carbide technology, which is applied in the field of modified WC/Co cemented carbide materials and its manufacturing, can solve the problems of difficult control of grain growth in the sintering process, high requirements for process parameters, and complex preparation processes. , to achieve the effect of dense arrangement, low requirements on process parameters and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

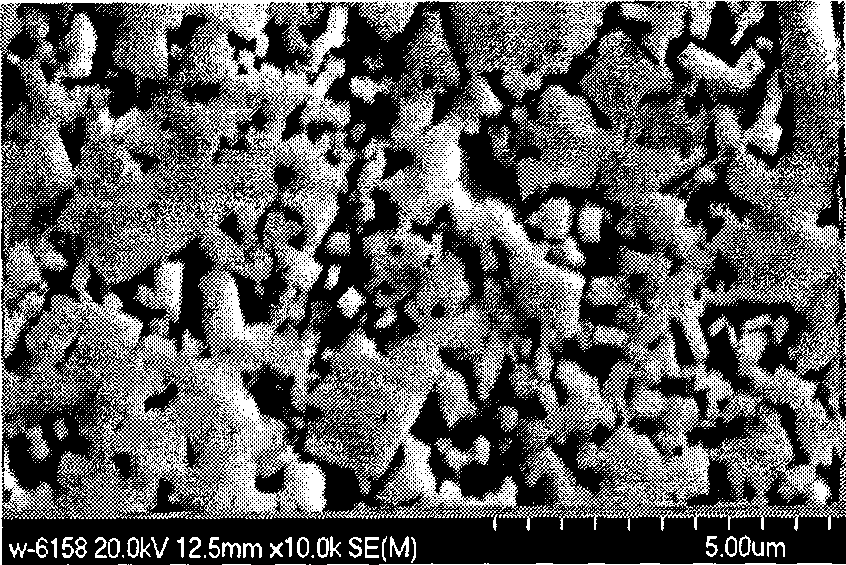

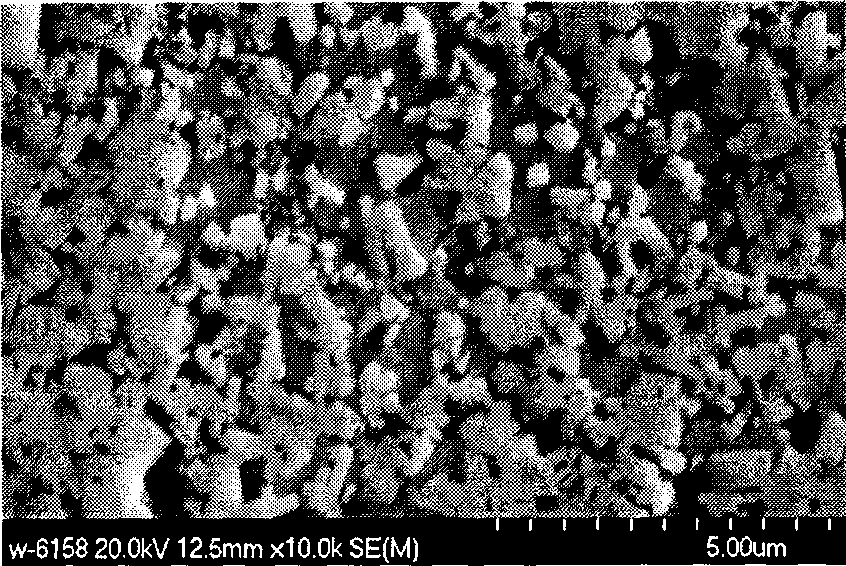

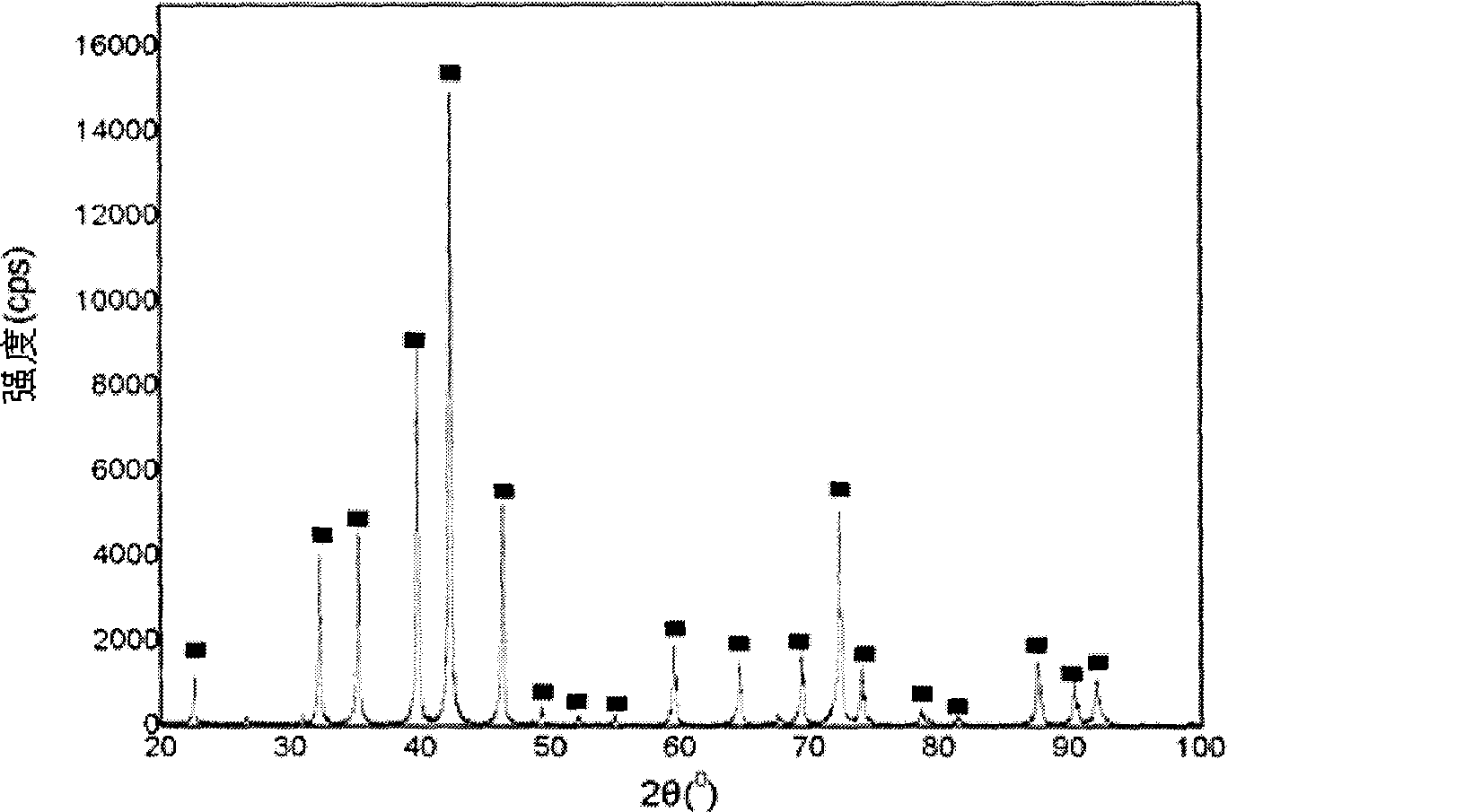

[0012] Specific embodiment 1: The nano-modified WC / Co cemented carbide material in this embodiment is made of 0.005% to 3.00% nano-modified material and the balance of WC / Co cemented carbide by mass percentage; wherein WC / Co hard alloy The mass content of Co in the alloy is 3% to 30%; the particle size of the nano-modified material is 1-500nm; the nano-modified material is composed of component A, component B and / or component C, component A is a rare earth element, and component B It is a rare earth compound, and the component C is selected from TiC, TiN, TiCN, WC, B 4 C, BN, SiC and Si 3 N 4 .

[0013] In this embodiment, the nano-modified material is composed of two or more substances, and the relationship between the various components can be in any proportion.

[0014] In this embodiment, if component C is composed of two or more substances, the relationship between the components can be in any proportion.

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the nano-modified WC / Co cemented carbide material is composed of 0.01% to 2.00% of nano-modified materials and the balance of WC / Co hard alloy by mass percentage. Made of quality alloy. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the nano-modified WC / Co cemented carbide material is composed of 0.1% to 1.00% nano-modified material and the balance of WC / Co hard alloy by mass percentage. Made of quality alloy. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com