Method for preparing MgZnO single crystal film

A single crystal thin film, zinc oxide thin film technology, applied in the field of preparation of MgZnO single crystal thin film, can solve the problems that single wurtzite phase MgZnO thin film is difficult to obtain, high Mg component thin film is prone to phase separation, etc., to achieve the suppression of phase separation Formation, good reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for manufacturing a wurtzite phase MgZnO single crystal film with a Mg composition up to 49% on a sapphire-based zinc oxide film:

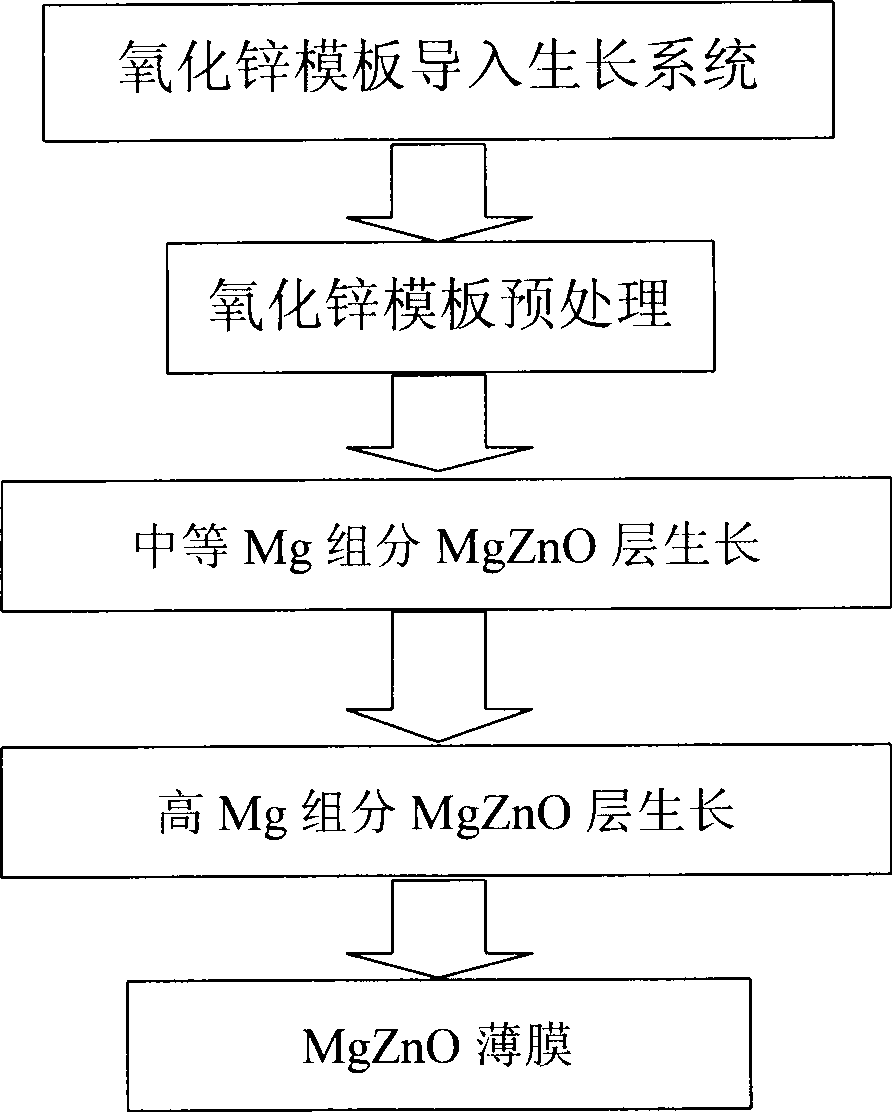

[0024] Such as figure 1 The process flow diagram of the present invention shown, utilizes the method for preparing zinc polar zinc oxide thin film on sapphire substrate, obtains zinc oxide template, further utilizes the real-time monitoring metal source beam current variation method in active gas environment, to Mg, Zn The beam flow is precisely controlled, so that the wurtzite phase MgZnO single crystal film with a Mg composition as high as 49% is prepared. The specific steps are:

[0025] 1) Using the molecular beam epitaxy method, import the zinc oxide template prepared on the sapphire substrate into the growth chamber, and then perform pretreatment, that is, under the ultra-high vacuum (UHV) condition, the zinc oxide template is heated to 750°C for 30 Minute heat treatment, and then 30 minutes active oxygen plasma treatment on...

Embodiment 2

[0032] The method for manufacturing the Mg composition on the silicon-based zinc oxide film is 47% wurtzite phase MgZnO single crystal film:

[0033] Such as figure 1 The process flow diagram of the present invention shown, utilizes the method for preparing zinc polar zinc oxide thin film on Si(111) substrate to obtain zinc oxide template, further utilizes the real-time monitoring metal source beam current variation method in active gas environment, to Mg , Zn beam flow was precisely controlled, thus preparing a wurtzite phase MgZnO single crystal thin film with a Mg composition as high as 47%. The specific steps are as follows:

[0034]1) Using the molecular beam epitaxy method, the zinc oxide template prepared on the Si(111) substrate is introduced into the growth chamber, and then pretreated. That is, under ultra-high vacuum (UHV) conditions, the zinc oxide template is heated to 600°C for 30 minutes of heat treatment, and then the surface of the substrate is treated with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com