Organic light emitting device using high conductive hole transport material as hole transport layer

A technology of hole transport materials and electroluminescent devices, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device manufacturing, etc., can solve the problems of hindering hole injection, expensive, complicated preparation process, etc., and achieve brightening The effect of low voltage and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The 2-TNATA, TCTA, TDAPB, TDATA, NPD, TPD, s-TAD, m-MTDATA used are commercial products. The conductive film indium tin oxide ITO is used as the electrode 2 to cover the glass substrate 1, and the glass substrate containing ITO is also a commercial product.

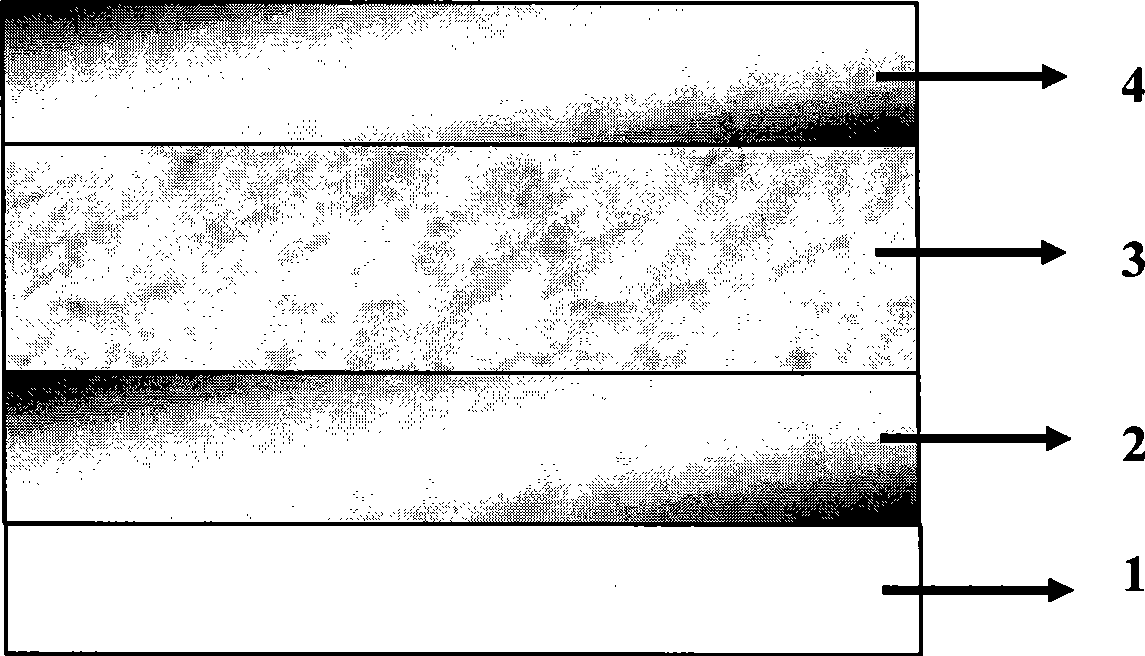

[0029] Diode structure composed of metal oxide doped hole transport material see figure 2 . Clean the ITO on the ITO glass first, dry it with nitrogen gas, and then treat it with oxygen plasma for 2 minutes. Then, in a vacuum of 1-5 x 10 -4 In Pa's coating system, a 100nm-thick metal oxide-doped hole transport material is evaporated on the processed ITO electrode as the active layer 3 . The organic host material in the metal oxide doped hole transport material is any one of 2-TNATA, TCTA, TDAPB, TDATA, NPD, TPD, s-TAD, m-MTDATA, and the metal oxide is pentoxide Vanadium (V 2 o 5 ), molybdenum trioxide (MoO 3 ), tungsten trioxide (WO 3 ), and finally deposit metal aluminum (Al) on the organic semiconductor ...

Embodiment 2

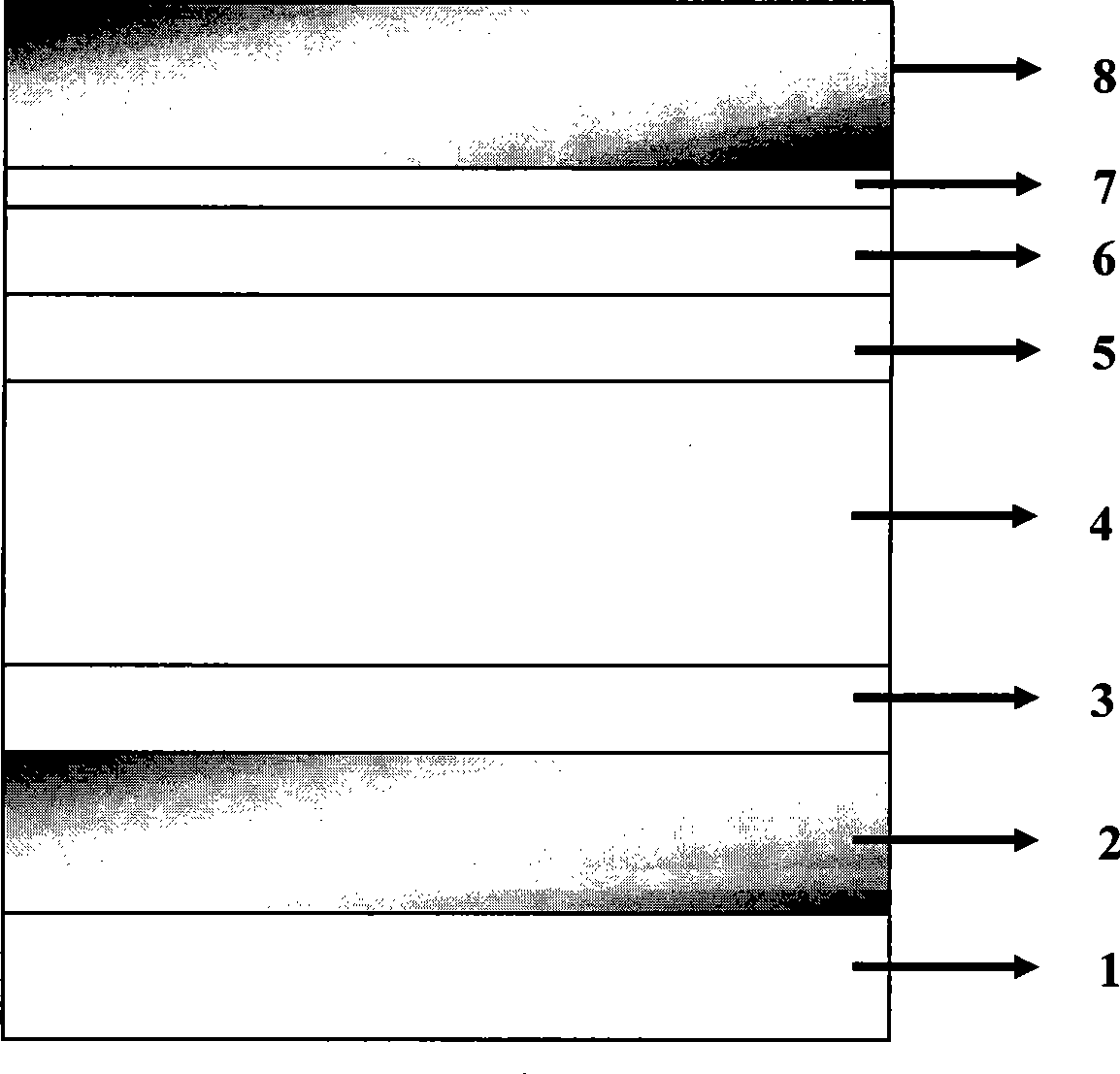

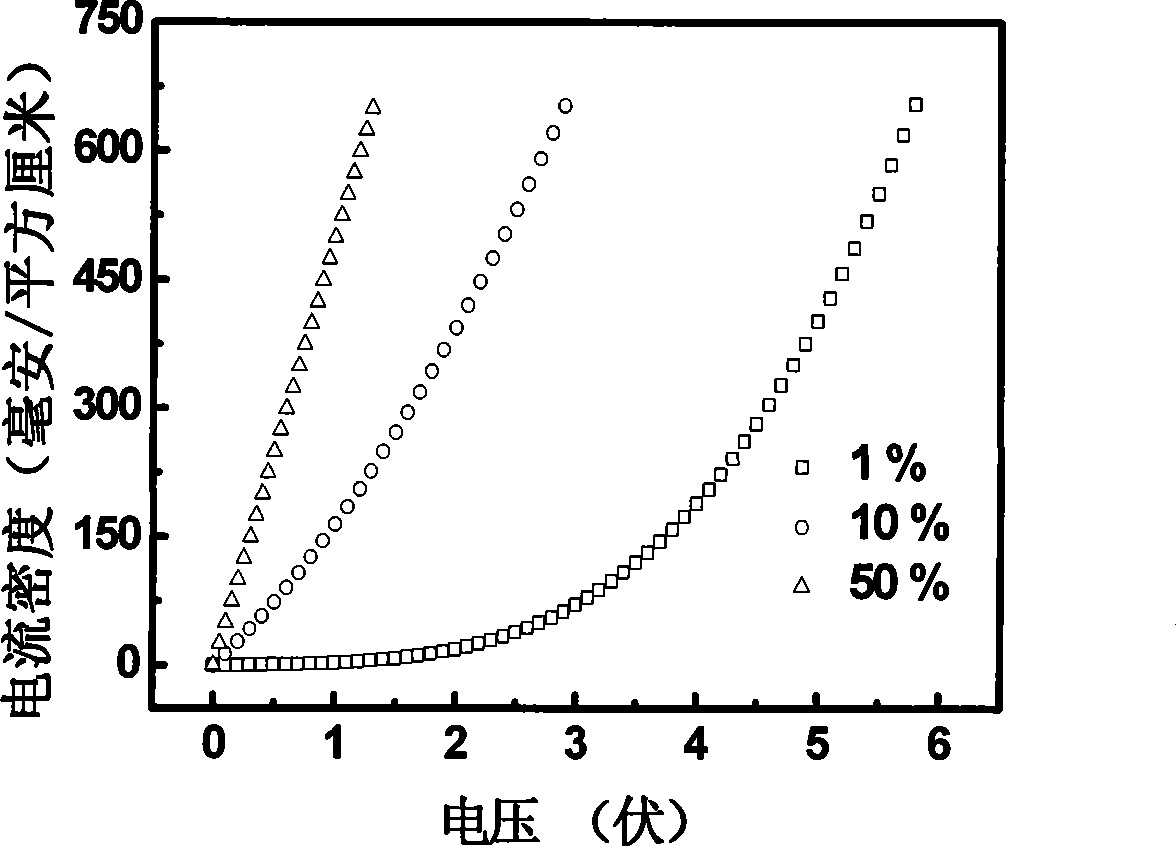

[0035] Structure of organic electroluminescent devices with high conductivity metal oxide doped organic hosts as hole injection transport layer see figure 1 . Clean the ITO on the ITO glass first, dry it with nitrogen gas, and then treat it with oxygen plasma for 2 minutes. After that, in a vacuum of 1-5×10 -4 In Pascal's coating system, 30 nanometers thick MoO is sequentially evaporated on the processed ITO electrode 2 3 Doped NPB hole injection layer 3, 100nm thick NPB hole transport layer 4, 30nm thick C545T doped Alq 3 The light-emitting layer of 5, 30nm thick Alq 3 Electron transport layer 6, 1nm thick lithium fluoride buffer layer 7 and 200nm thick A1 electrode 8, prepared as ITO / MoO 3 :NPB / NPB / C545TAlq 3 / Alq 3 / LiF / Al organic electroluminescent devices. Organic electroluminescent devices with an active area of 25 mm2, MoO 3 The doping concentration in NPB was 10% by weight. attached image 3 b shows the current density-brightness-voltage characteristic curv...

Embodiment 3

[0037] Structure of organic electroluminescent devices with high conductivity metal oxide doped organic hosts as hole injection transport layer see figure 1 . Clean the ITO on the ITO glass first, dry it with nitrogen gas, and then treat it with oxygen plasma for 2 minutes. After that, in a vacuum of 1-5×10 -4 In Pascal's coating system, 30 nanometers thick MoO is sequentially evaporated on the processed ITO electrode 2 3 Doped NPB hole injection layer 3, 60nm thick NPB hole transport layer 4, 30nm thick C545T doped Alq 3 The light-emitting layer of 5, 30nm thick Alq 3 The electron transport layer 6, the lithium fluoride buffer layer 7 with a thickness of 1nm and the Al electrode 8 with a thickness of 200nm are prepared into a structure of ITO / MoO 3 :NPB / NPB / C545TAlq 3 / Alq 3 / LiF / Al organic electroluminescent devices. Organic electroluminescent devices with an active area of 25 mm2, MoO 3 The doping concentration in NPB was 1% by weight. The turn-on voltage of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com