Abrasion-proof self-lubricating composite material and its preparation

A composite material and self-lubricating technology, which is applied in the field of wear-resistant and self-lubricating composite materials and their preparation, can solve the problems of undiscovered coating of solid lubricants, etc., and achieve the effect of high load, less wear and short running-in period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

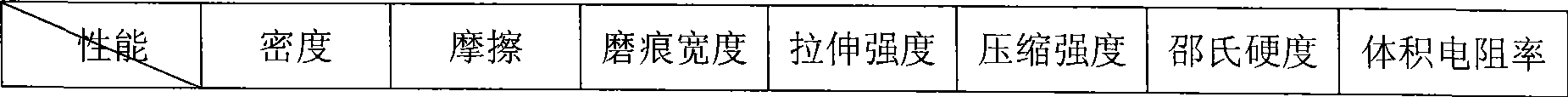

[0023] The formula of embodiment 1

[0024] raw material PTFE polyphenylene Tin Bronze Fiber glass beads Weight percent (wt%) 60 10 20 10

[0025] The wear-resistant self-lubricating composite material prepared by the above formula, its preparation method comprises the following steps in turn:

[0026] A. Polyphenylene fine powder 5-30%, tin bronze fiber 10-45%, glass microspheres, spherical SiO 2 or Al 2 o 3 Mix 2-15% of the particles and the rest of the suspended PTFE resin molding powder, put it into the mold, hold the pressure for 1-10min under 40-80MPa, and press to form;

[0027] B. Put the product into a high-temperature sintering furnace, the sintering stage rate is 50-100°C / h, keep it at 330°C for 1-1.5h, then raise the temperature to 370-385°C, and keep it for 2-3 hours;

[0028] C. Put the product into acetone, clean it with ultrasonic waves, then protect the non-working surface to expose the frictional working surface, put it into ...

Embodiment 2

[0035] The formula of embodiment 2

[0036] raw material PTFE polyphenylene Tin Bronze Fiber glass beads Weight percent (wt%) 55 10 30 5

[0037] The high wear-resistant self-lubricating composite material prepared according to the above formula, its preparation method is the same as that of Example 1.

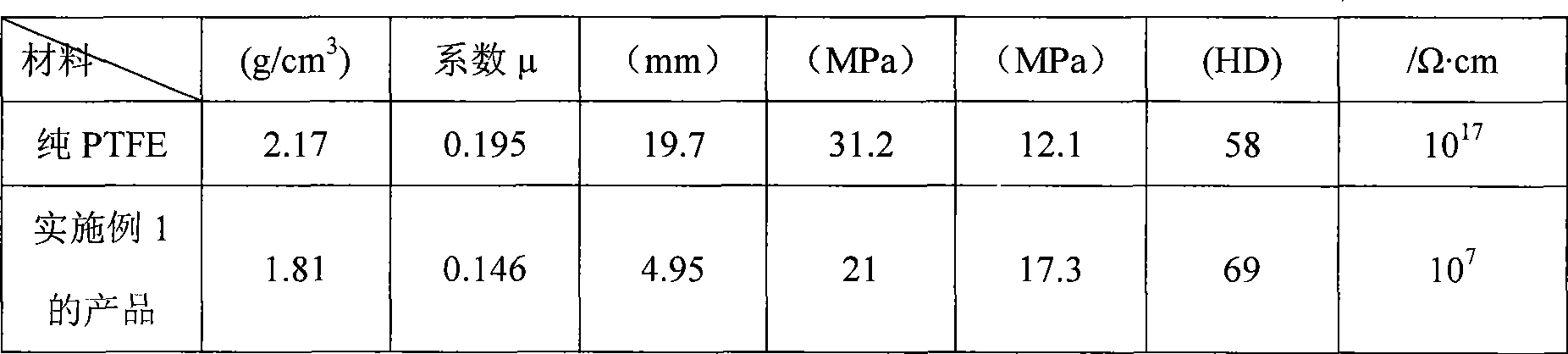

[0038] The product of embodiment 2 and the performance contrast of pure polytetrafluoroethylene

[0039]

[0040] This material is suitable for wear-resistant, self-lubricating or dynamic sealing parts in water, such as high-pressure water pump dynamic sealing parts.

Embodiment 3

[0042] The formula of embodiment 3

[0043] raw material PTFE polyphenylene Tin Bronze Fiber Spherical SiO 2 Weight percent (wt%) 45 13 40 2

[0044] The high wear-resistant self-lubricating composite material prepared according to the above formula, its preparation method is the same as that of Example 1.

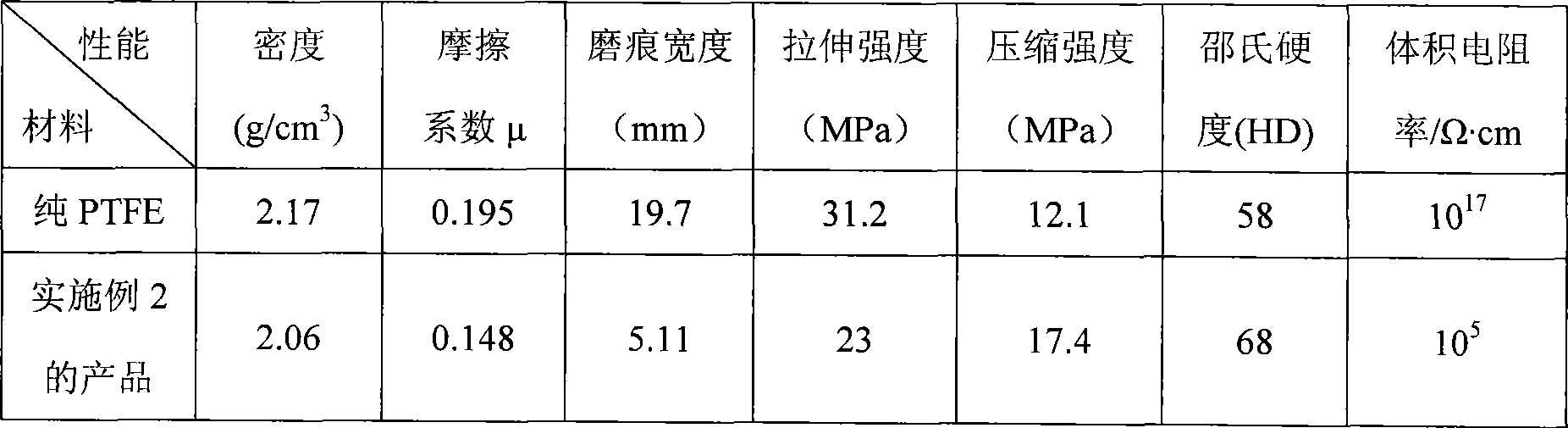

[0045] The product of embodiment 3 and the performance contrast of pure polytetrafluoroethylene

[0046]

[0047]

[0048] This material is suitable for occasions with large dust and antistatic requirements, such as transmission parts or sealing parts in coal mines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com