Tinning method for SMD stamp-mounting-paper diode

A diode and chip technology, applied in the field of tin plating of SMD chip diodes, can solve the problems such as the inability to suppress the formation of tetravalent tin, the physical injury of operators, and the inability to adapt to environmental pollution, so as to shorten the plating time and reduce personal injury. , to maintain long-term stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

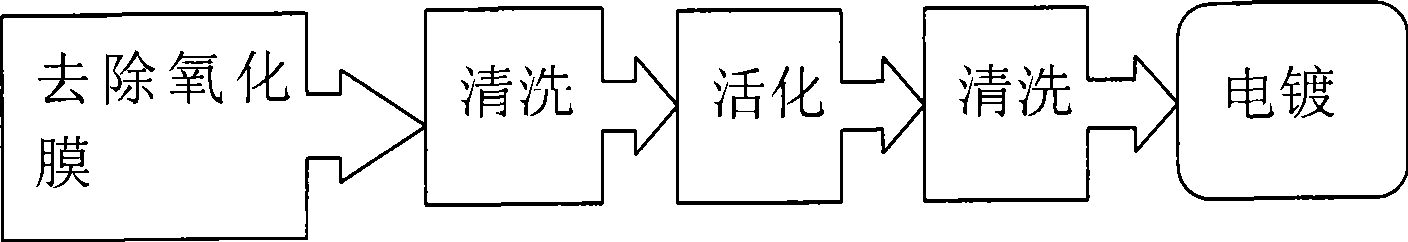

[0026] refer to figure 1 , the tinning method of SMD chip diode of the present invention, realizes by following steps:

[0027] 1. Remove the oxide film:

[0028] An oxide film whose main component is copper oxide is formed on the surface of the SMD chip diode. During electroplating, the pin and the plating solution will be separated by the oxide film. If it is not treated, it cannot be used for direct electroplating. Even if it is plated with tin, the tin layer will not be firmly bonded to the surface of the substrate, otherwise it will cause blistering of the coating, Peeling, even can not be plated with tin, etc. Therefore, deoxidation film is an indispensable and important link in the electroplating process. In this embodiment, the sulfuric acid solution with a concentration of 10% is used to remove the oxide film on the surface of the pins of the SMD chip diode.

[0029] Two, cleaning

[0030] The surface of the SMD chip diode is stained with sulfuric acid residue and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com