Distribution of current blocking layer, LED corresponding to the upper electrode and preparation thereof

A technology of current blocking layer and light emitting diode, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of weak lateral current expansion capability of the current expansion layer, low device luminous efficiency, poor thermal characteristics, etc., so as to improve light extraction. Efficiency and luminous intensity, simple process, effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

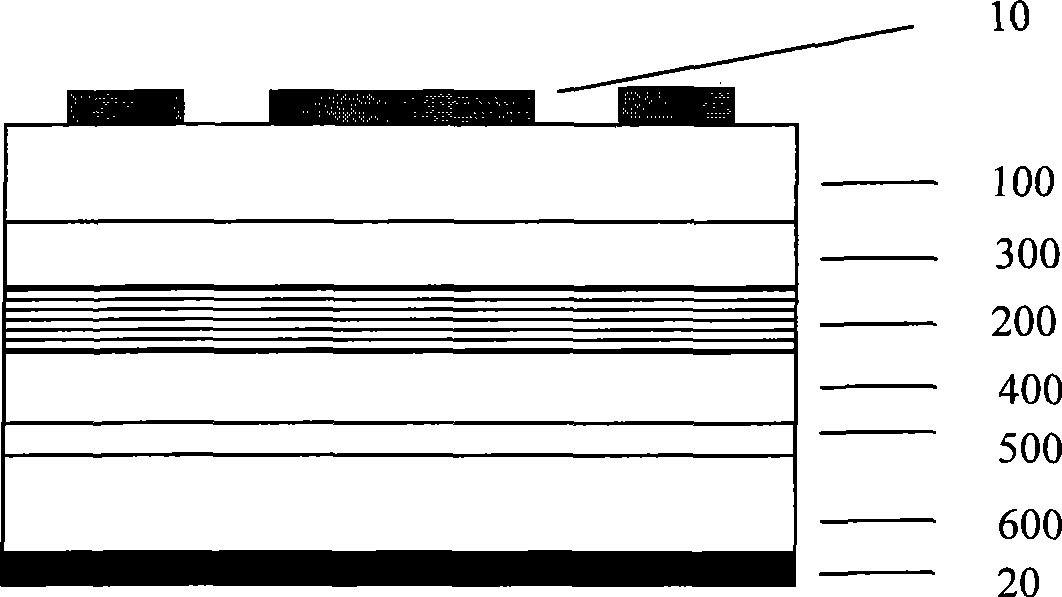

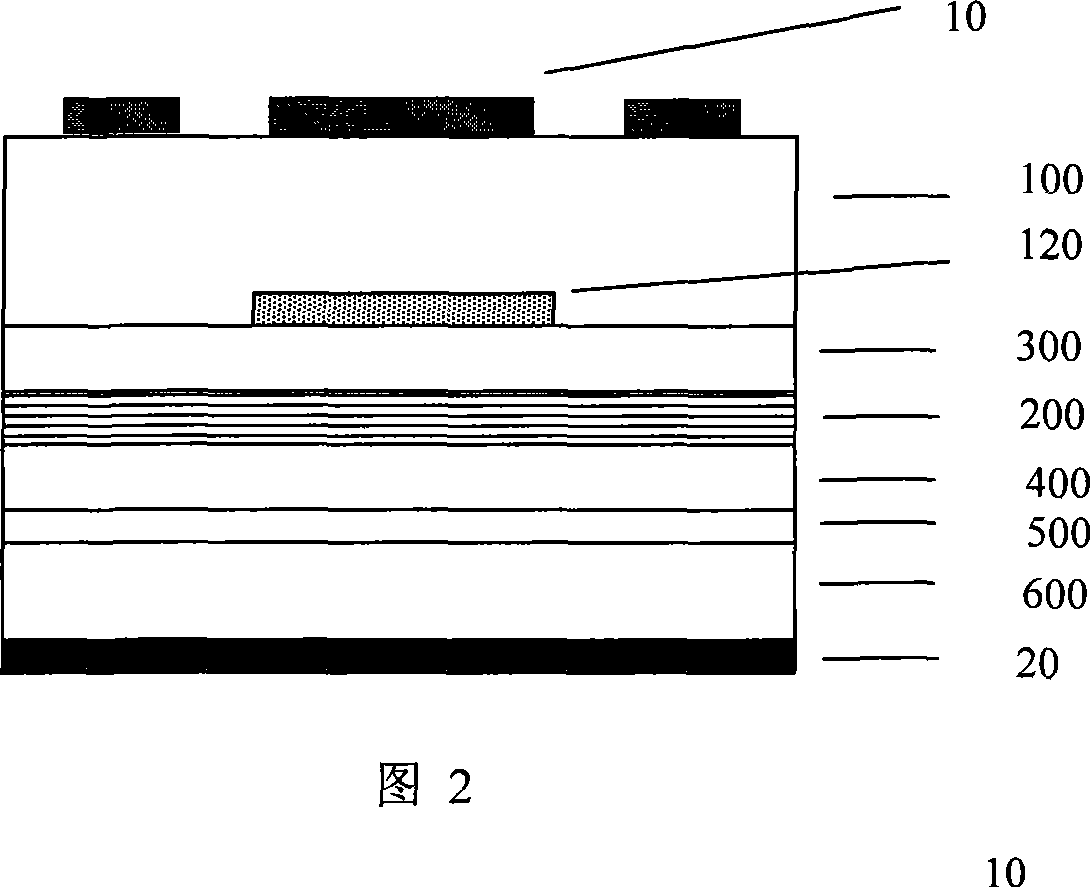

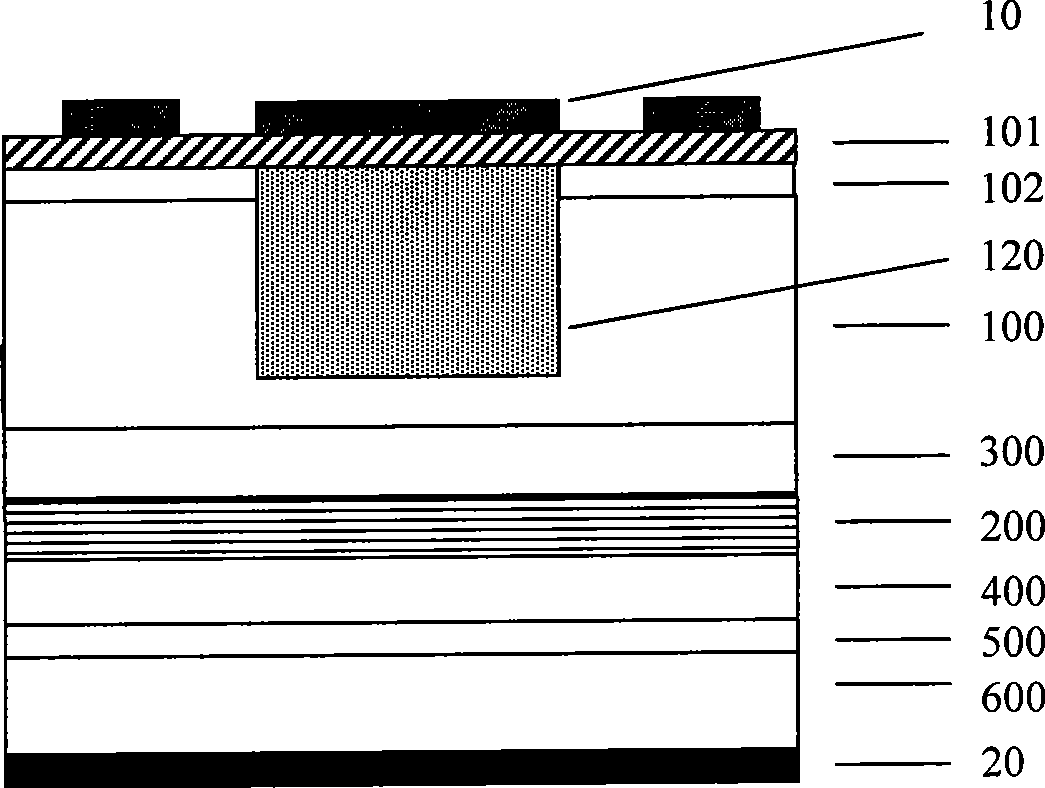

[0033] Such as Figure 7 As shown, take AlGaInP LED as an example. The device consists of the following parts: an upper electrode 10, a conductive optical anti-reflection layer 101, a current spreading layer 100, an upper confinement layer 300, an active region 200, a lower confinement layer 400, a buffer layer 500, a substrate 600, and a lower electrode 20 , the current blocking layer 120 is located inside the upper confinement layer 300 and the active region 200; its preparation process and method are as follows:

[0034]1. On the n-type substrate 600 formed by GaAs and other materials that can match AlGaInP, the buffer layer 500, the lower confinement layer 400, the active region 200, the upper confinement layer 300, and the current spreading layer 100 are epitaxially grown in sequence by MOVCD method , so that the epitaxial wafer of AlGaInP light-emitting diode is obtained;

[0035] 2. Then through the post-processing method: firstly, the epitaxial wafer is cleaned, the ...

Embodiment 2

[0038] In the present invention, the distribution of the current blocking layer corresponds to the light-emitting diode of the upper electrode, such as Figure 7 shown, where:

[0039] 1. In the present invention, the shape of the upper electrode 10 can be circular, star-shaped, strip-shaped, finger-shaped or other shapes, and the diameter of the welding spot can be 100 μm, 80 μm or other sizes.

[0040] 2. The material of the current blocking layer 120 can be an insulating material such as an intrinsic semiconductor, a non-conductive resin, non-doped amorphous Si, SixNy and SixOy, or a conductive material opposite to the conductive type of the conductive optical anti-reflection layer 101;

[0041] 3. The structure of the active region 200 is a p-n junction, or a p-i-n junction, or a double heterostructure, or a single quantum well structure, or a multi-quantum well structure, a superlattice structure, or a quantum dot light-emitting structure, or a multilayer quantum dot stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com