Method for preparing yttrium silicate nano powder

A technology of nano-powder and yttrium silicate, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., can solve the problems of long cycle, high preparation temperature, complicated process, etc., and achieve short reaction cycle and low preparation cost , the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

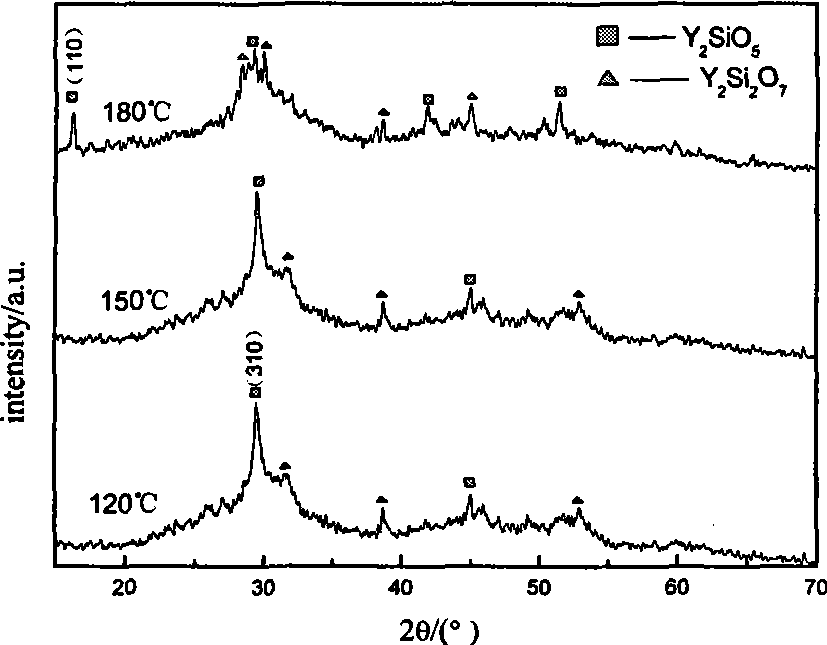

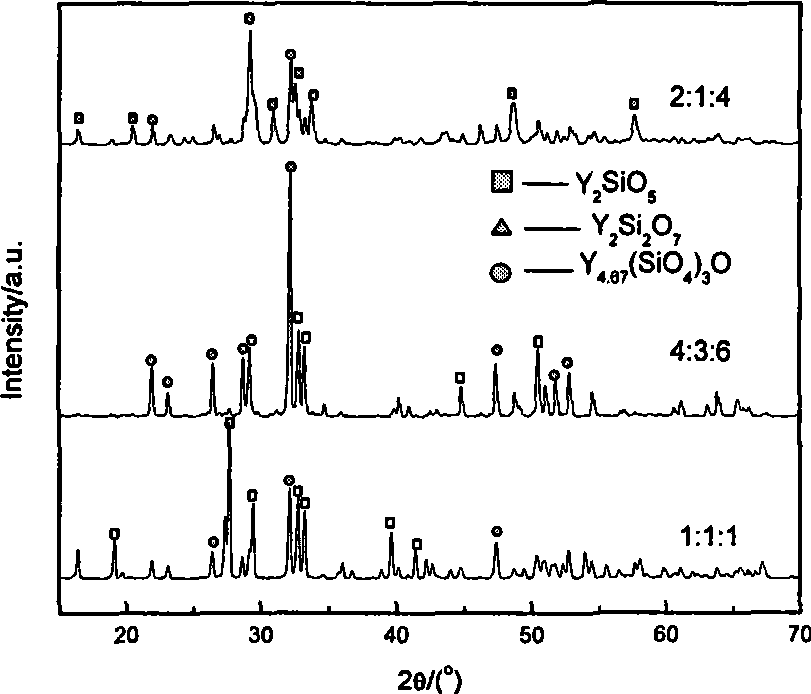

Embodiment 1

[0018] 1) The analytically pure Y(NO 3 ) 3 ·6H 2 O, Na 2 SiO 3 9H 2 O and NaOH were added into distilled water and stirred continuously to prepare a transparent solution with a concentration of 0.5mol / L, in which Y(NO 3 ) 3 : Na 2 SiO 3 : The molar ratio of NaOH is 2:1:4, and it is stirred continuously to form a precursor solution, and the obtained solution is recorded as A solution;

[0019] 2) Pour the A solution prepared above into the hydrothermal reaction kettle, and the filling degree is controlled at 60%; then seal the hydrothermal reaction kettle, and put it into the MDS-6 type temperature-pressure dual-control microwave hydrothermal reaction apparatus; The hydrothermal temperature is controlled at 180°C, and the reaction time is controlled at 10 minutes. After the reaction is completed, it is naturally cooled to room temperature, and the obtained solution is recorded as B solution;

[0020] 3) Open the hydrothermal reaction kettle, filter B solution through f...

Embodiment 2

[0023] 1) The analytically pure Y(NO 3 ) 3 ·6H 2 O, Na 2 SiO 3 9H 2 Add O and NaOH into distilled water, and keep stirring to prepare a transparent solution with a concentration of 0.7mol / L, in which Y(NO 3 ) 3 : Na 2 SiO 3 : The molar ratio of NaOH is 2:1:4, and it is stirred continuously to form a precursor solution, and the obtained solution is recorded as A solution;

[0024] 2) Pour the above-prepared A solution into the hydrothermal reaction kettle, and the filling degree is controlled at 60%; then seal the hydrothermal reaction kettle, and put it into the MDS-6 type temperature-pressure dual-control microwave hydrothermal reaction apparatus; The hydrothermal temperature is controlled at 180°C, and the reaction time is controlled at 10 minutes. After the reaction is completed, it is naturally cooled to room temperature, and the obtained solution is recorded as B solution;

[0025] 3) Turn on the hydrothermal reaction kettle, filter B solution through filter pape...

Embodiment 3

[0029] 1) The analytically pure Y(NO 3 ) 3 ·6H 2 O, Na 2 SiO 3 9H 2 O and NaOH were added into distilled water and stirred continuously to prepare a transparent solution with a concentration of 0.6mol / L, in which Y(NO 3 ) 3 : Na 2 SiO 3 : The molar ratio of NaOH is 2:1:4, and it is stirred continuously to form a precursor solution, and the obtained solution is recorded as A solution;

[0030] 2) Pour the A solution prepared above into the hydrothermal reaction kettle, and the filling degree is controlled at 60%; then seal the hydrothermal reaction kettle, and put it into the MDS-6 type temperature-pressure dual-control microwave hydrothermal reaction apparatus; The hydrothermal temperature is controlled at 150°C, and the reaction time is controlled at 10 minutes. After the reaction is completed, it is naturally cooled to room temperature, and the obtained solution is recorded as B solution;

[0031] 3) Turn on the hydrothermal reaction kettle, filter B solution throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com