Hole blackening solution and preparation thereof

A technology of black hole solution and suspension solution, which is used in liquid chemical plating, printed circuit manufacturing, printed circuit and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

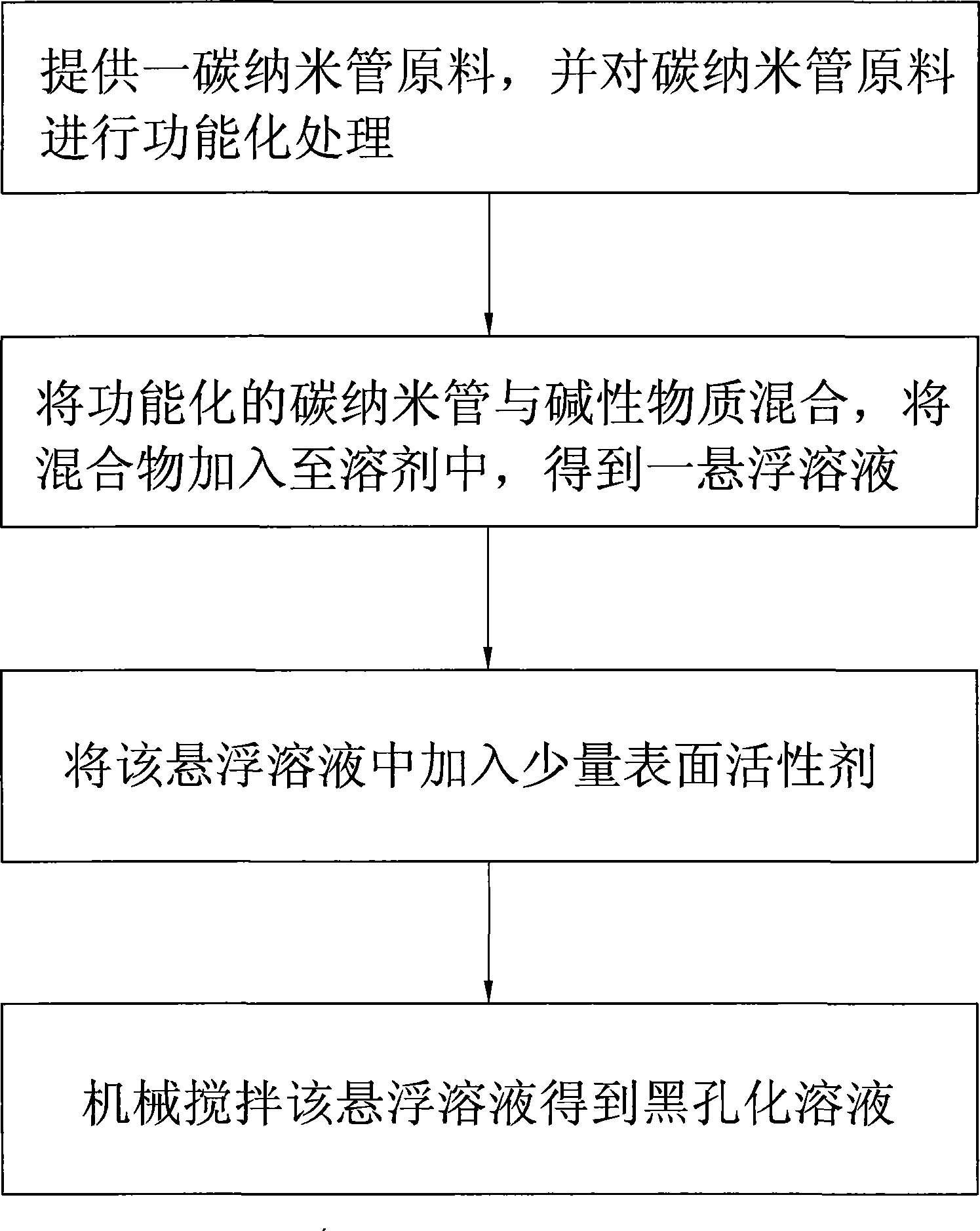

[0016] see figure 1 , the technical solution provides a method for preparing a black hole solution, which mainly includes the following steps:

[0017] (1) Provide a carbon nanotube raw material, and perform functional treatment on the carbon nanotube raw material.

[0018] In this embodiment, the carbon nanotube raw material can be single-walled or multi-walled carbon nanotubes prepared by arc discharge method, laser evaporation method or chemical vapor deposition method, wherein carbon nanotube arrays grown by chemical vapor deposition method are preferred . In the carbon nanotube array, because the carbon nanotubes are aligned and not entangled with each other, it is beneficial for the carbon nanotubes to disperse in the solution. The aspect ratio of carbon nanotubes is greater than 1000:1. A large aspect ratio is conducive to the formation of a conductive network of carbon nanotubes.

[0019] The above-mentioned carbon nanotube raw material functionalization treatment ...

Embodiment

[0044] The carbon nanotube raw material was placed in a furnace at 350° C. and heated in air flow for 2 hours to remove amorphous carbon in the carbon nanotube raw material. Then the remaining carbon nanotube raw material in the furnace was soaked in 36% concentrated hydrochloric acid for 1 day and then centrifuged, and the obtained precipitate was repeatedly washed with deionized water. The purified carbon nanotube raw material was obtained by filtering through a polytetrafluoroethylene membrane with a pore size of 0.2 mm. 80 mg of the purified carbon nanotube raw material was heated under reflux in 2.6 M nitric acid for 48 hours, and filtered through a filter membrane with a pore size of 100 nm to obtain a carbon nanotube solid. Repeated washing with deionized water until the pH value of the filtrate was 7. A certain amount of the functionalized carbon nanotubes and a certain amount of potassium carbonate were weighed. Mix the above potassium carbonate and the functionaliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com