Asiatic centella extract and preparation methode thereof

A Centella asiatica extract and extract technology are applied in the directions of drug combination, pharmaceutical formula, plant raw material, etc., can solve problems such as being unsuitable for industrial large-scale production, achieve controllable product quality, reduce physical and mental damage, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1 Preparation method of extract

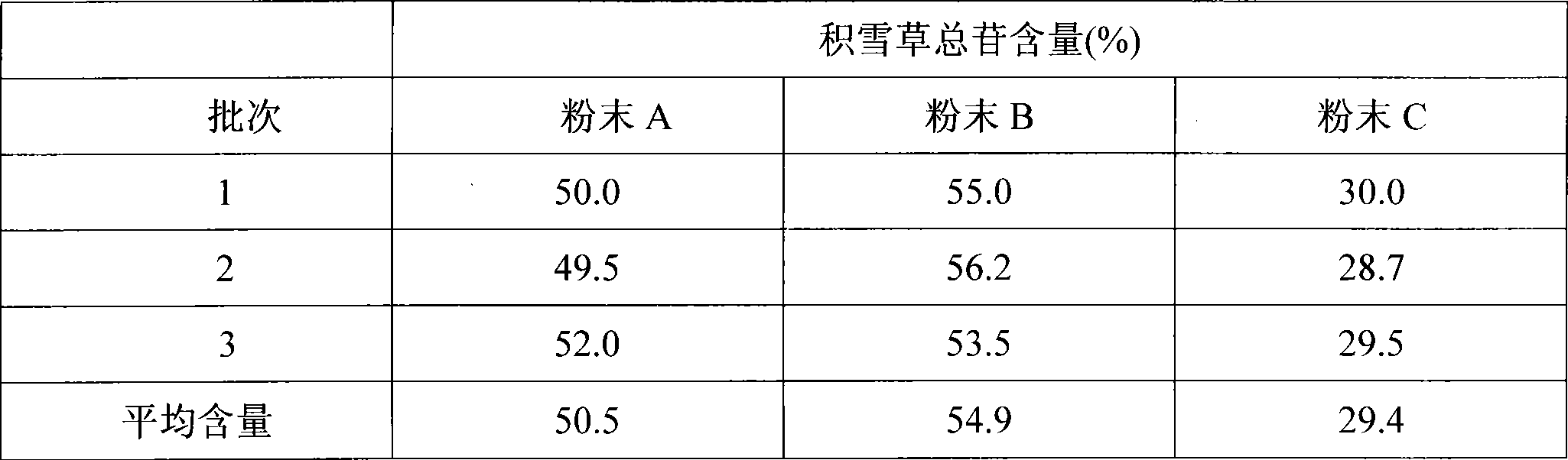

[0075] Centella asiatica herbal material is crushed into coarse powder, extracted with 60% ethanol and refluxed twice for 2 hours each time. The amount of 60% ethanol for the first time is 10 times that of the medicinal material, and the second time is 8 times. Filter, combine the filtrate, and add 0.2% activated carbon is refluxed for 30 minutes to decolorize, filter while hot, and concentrate under reduced pressure to recover ethanol to a thick extract without alcohol. The thick extract is adjusted with water to 3:1 (volume and amount of medicinal materials) liquid, filtered, and on the filtrate AB-8 resin adsorption, eluted with 4 column volume of water, 20% ethanol, 30% ethanol, 6 column volume of 40% ethanol, 4 column volume of 50% ethanol, and collected 30% respectively. , 40%, 50% ethanol elution part, the three eluates are concentrated under reduced pressure to a specific gravity of 1.10-1.15, and dried under reduced pressur...

Embodiment 2

[0076] Example 2 Preparation method of extract

[0077] Centella asiatica herbal material was crushed into coarse powder, extracted with 10% ethanol and refluxed twice for 3 hours each time. The amount of 10% ethanol for the first time was 10 times that of the medicinal material, and the second time was 8 times. Filtered, combined the filtrate, and added 0.2% activated carbon is refluxed for 20 minutes to decolorize, filter while hot, and concentrate under reduced pressure to recover ethanol to a thick extract without alcohol. The thick extract is adjusted with water to 2:1 (volume and amount of medicinal material) medicinal solution, filtered, and on the filtrate AB-8 resin adsorption, eluted with 4 column volume of water, 20% ethanol, 30% ethanol, 6 column volume of 40% ethanol, 4 column volume of 50% ethanol, and collected 30% respectively. , 40%, 50% ethanol elution part, the three eluates are concentrated under reduced pressure to a specific gravity of 1.10-1.15, and dried un...

Embodiment 3

[0078] Example 3 Preparation method of extract

[0079] Centella asiatica is crushed into coarse powder, extracted with 95% ethanol and refluxed once for 3 hours each time. The amount of 95% ethanol for the first time is 6 times that of medicinal materials, and the second time is 12 times. Filter, combine the filtrate, and add 0.2% activated carbon is refluxed for 40 minutes to decolorize, filter while hot, and concentrate under reduced pressure to recover ethanol to a thick extract without alcohol. The thick extract is adjusted to a 3:1 (volume and amount of medicinal material) medicinal solution (volume and amount of medicinal material) by adding water, filtered, and on the filtrate AB-8 resin adsorption, eluted with 4 column volume of water, 10% ethanol, 20%, 30% ethanol, 6 column volume of 40% ethanol, 4 column volume of 50% ethanol, 2 Elute with 90% ethanol in multiples, collect 10%, 20%, 30%, 40%, 50%, 90% ethanol elution fractions, and concentrate the five eluates under red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com