Intelligent full-bridge soft-switching potentiostat

A potentiostat and soft switching technology, applied in the field of corrosion and protection, can solve the problems of lag in the application process of the potentiostat device, large power loss of switching devices, and no public reports, and achieve novel structural principles and avoid current impact. , the effect of small product volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

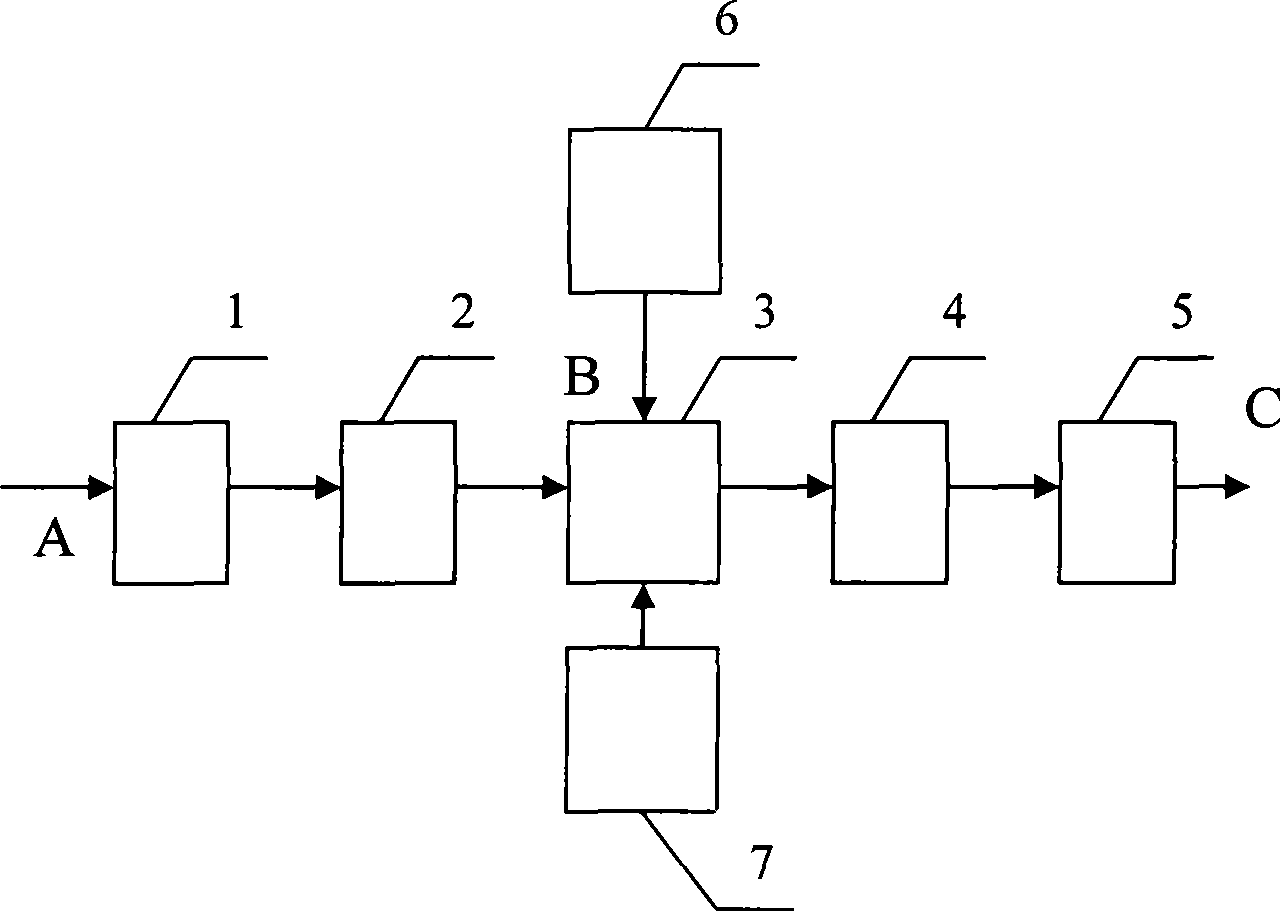

[0015] The main circuit of this embodiment is electrically connected by AC power rectification and filter circuits 1 and 2, full-bridge converter 3, soft switching circuit 7, high-frequency transformer 4, high-frequency output rectification and filter circuit 5, and pulse phase-shift control drive circuit 6. Combination structure; the input end of the AC rectification circuit 1 is connected to the AC input power supply, the output end is connected to the AC filter circuit 2, the output end of the AC filter circuit 2, the soft switching circuit 7, the pulse phase shift control drive circuit 6 and the input of the high frequency transformer 4 The ports are electrically connected to the full-bridge converter 3 in principle, the output end of the high-frequency transformer 4 is electrically connected to the input end of the high-frequency output rectification filter circuit 5, and the output end of the high-frequency output rectification filter circuit 5 outputs a DC power supply; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com