Method for improving anti-aging quality of rice-cake

An anti-aging, rice cake technology, applied in the direction of pre-baked dough processing, etc., to achieve the effect of improving anti-aging quality, meeting requirements, and improving chewiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

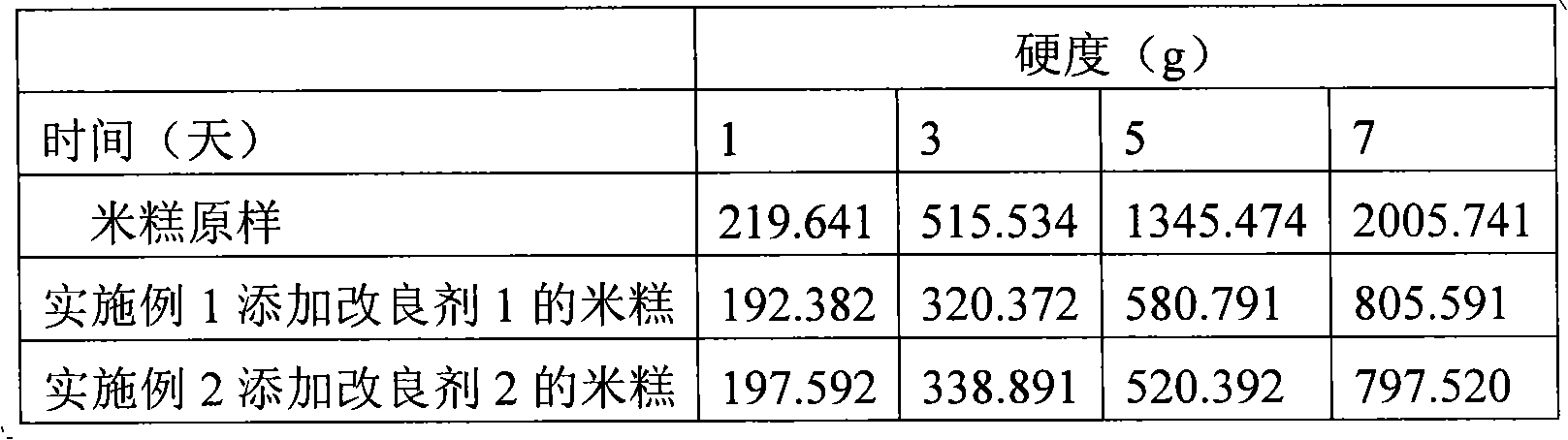

Embodiment 1

[0021] Embodiment 1: Formula: glutinous rice, japonica rice, white granulated sugar, drinking water, improver (xanthan gum, carboxymethyl starch, β-amylase, sucrose fat, sodium stearoyl lactylate or calcium stearoyl lactylate)

[0022] Production Method:

[0023] (1) Material selection: The formula mainly includes: 60 parts of glutinous rice, 40 parts of japonica rice, 15 parts of white sugar, 65 parts of drinking water, improver (xanthan gum, carboxymethyl starch, β-amylase, sucrose ester, stearin Sodium acyl lactylate or calcium stearoyl lactylate accounted for 0.2%, 0.25%, 0.03%, 0.2%, 0.3% of the total rice flour respectively); high-quality glutinous rice and japonica rice were soaked in water and cleaned, drained and ground into fine grains with a superfine pulverizer Rice flour, then sieve with 120 mesh to remove slag;

[0024] (2) Mixing material: Stir glutinous rice flour, japonica rice flour, drinking water, white sugar, and improver evenly into a ball;

[0025] (3)...

Embodiment 2

[0028] Embodiment 2: formula: glutinous rice, round-grained rice, white granulated sugar, drinking water, improver (fungus α-amylase, bacterium α-amylase, hydroxypropyl starch, guar gum, sodium stearoyl lactylate or stearoyl lactic acid calcium, monoglyceride);

[0029] Production Method:

[0030] (1) Material selection: The formula mainly includes: 40 parts of glutinous rice, 60 parts of japonica rice, 20 parts of white sugar, 60 parts of drinking water, improving agent (fungal α-amylase, bacterial α-amylase, hydroxypropyl starch, guar Soybean gum, sodium stearoyl lactylate or calcium stearoyl lactylate, and monoglyceride account for 0.4%, 0.02%, 2%, 0.5%, 0.3%, and 0.2% of the total rice flour respectively); high-quality glutinous rice and japonica rice are soaked in water and cleaned , drained and ground into fine rice flour with a superfine grinder, and then sieved to 120 mesh to remove slag;

[0031] (2) Mixing material: Stir glutinous rice flour, japonica rice flour, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com