Process for producing layered delta-MnO2 nano-particle

A nanoparticle and layered technology, applied in the field of preparation of MnO2, an electrode material for supercapacitors, can solve the problems of many chemical reagents, complex preparation methods, and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

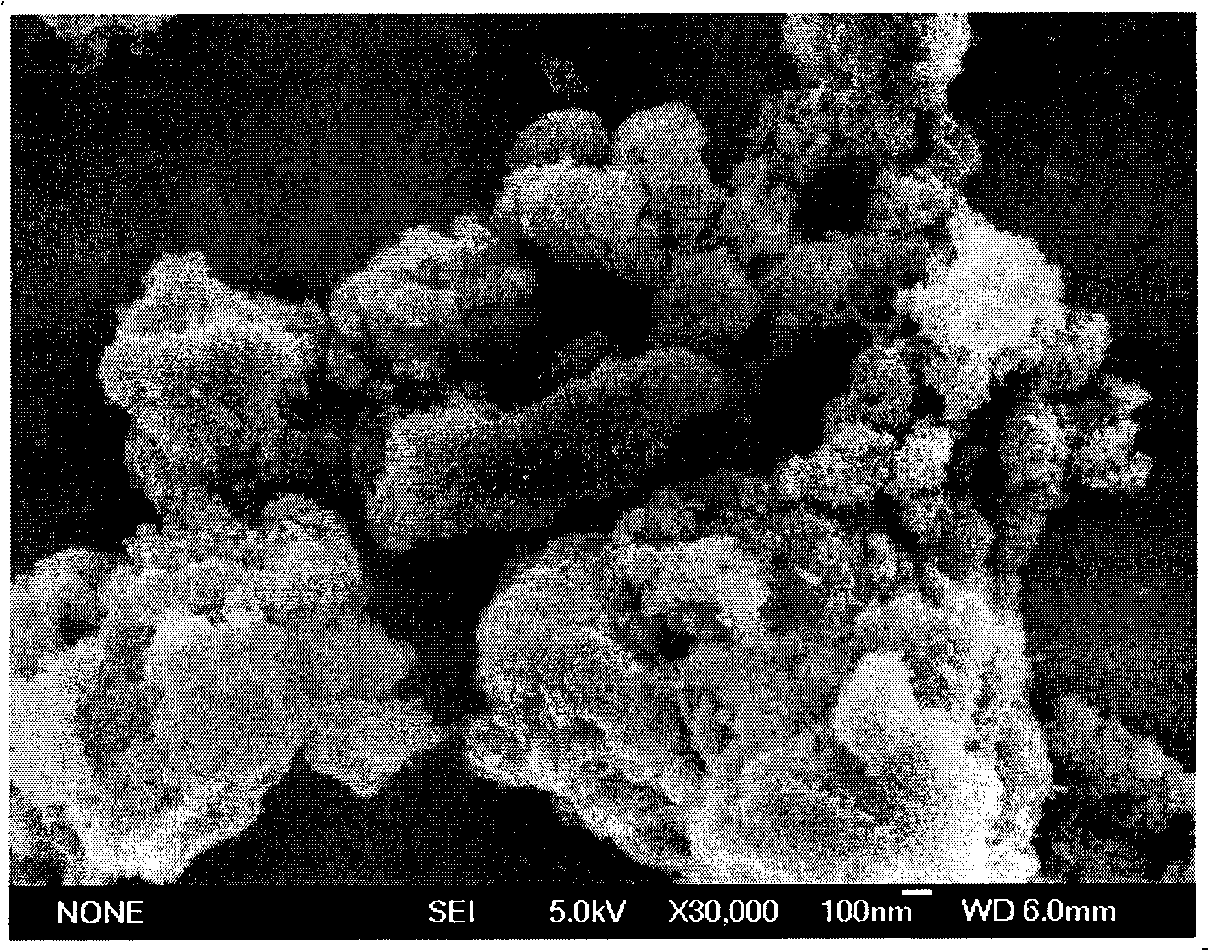

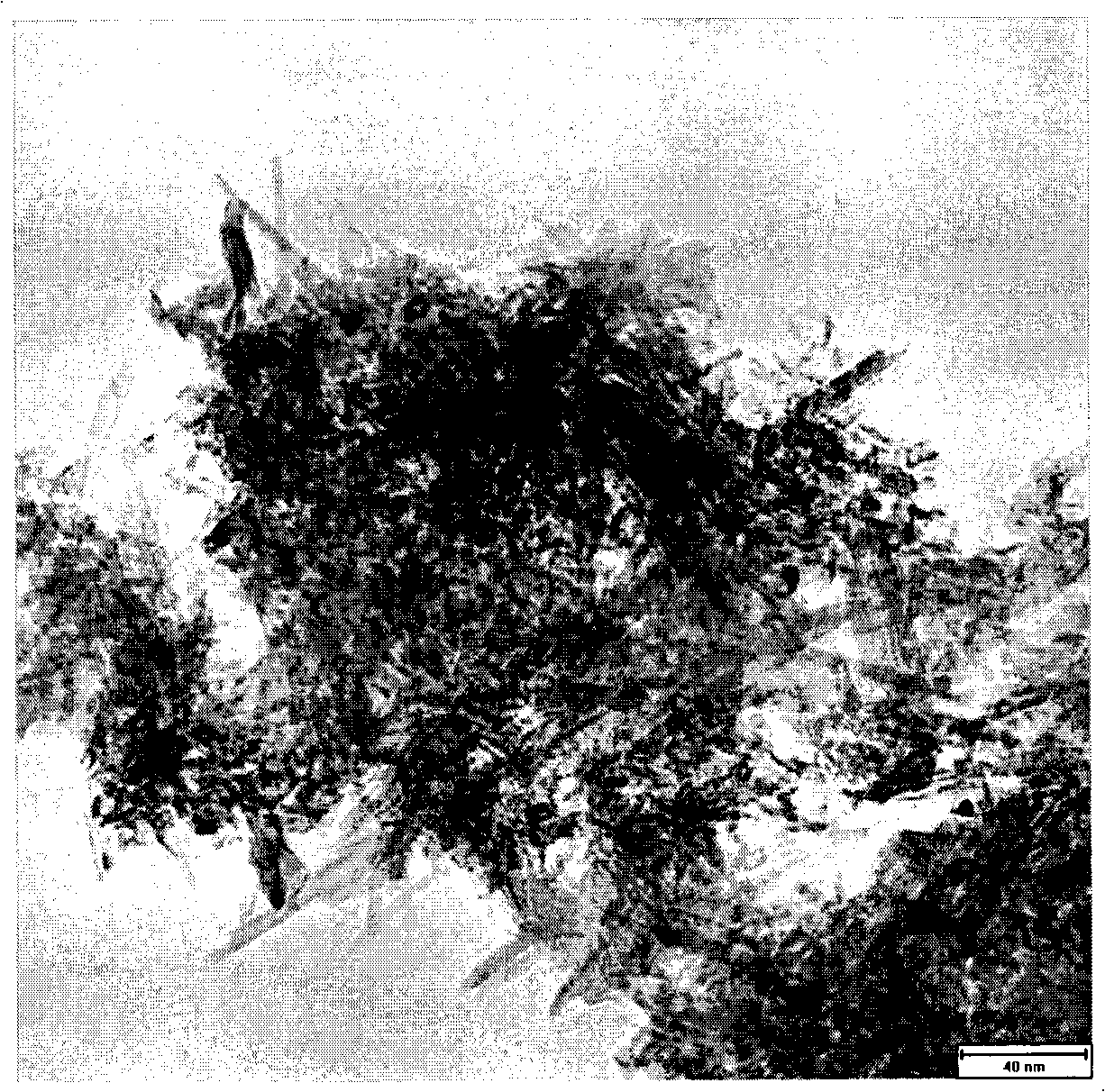

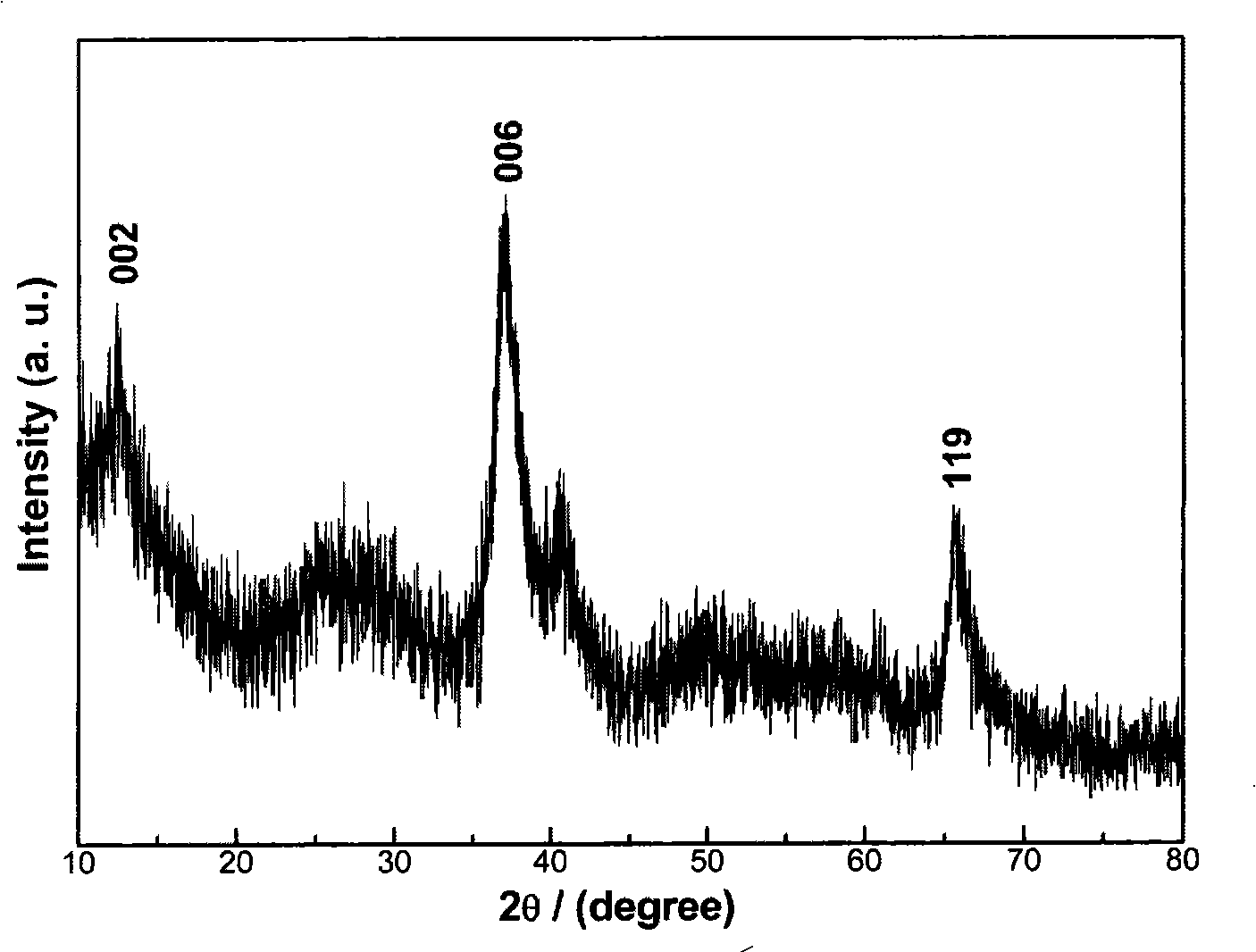

[0012] (1) Weigh potassium permanganate (KMnO 4 , ≥99.5), oleic acid (C 18 h 34 o 2 , relative density: 0.891~0.896g / mL at 20°C); potassium permanganate was completely dissolved in deionized water to form a solution, and then oleic acid was added to the solution and fully stirred to form a microemulsion; the above microemulsion was statically Put it in a microwave oven for 6 hours and heat it with 800 watts for 8 minutes. The obtained product was collected, washed by deionized water and absolute ethanol for 10 times, and then dried under air atmosphere to obtain layered δ-MnO 2 nanoparticles. figure 1 Shown is the resulting product δ-MnO 2 Scanning electron microscope pictures; figure 2 Shown is δ-MnO 2 TEM pictures of image 3 Shown is δ-MnO 2 The XRD patterns of the obtained MnO 2 layered δ-MnO 2 .

Embodiment 2

[0014] (1) Weigh potassium permanganate (KMnO 4 , ≥99.5), oleic acid (C 18 h 34 o 2 , relative density: 0.891~0.896g / mL at 20°C); potassium permanganate was completely dissolved in deionized water to form a solution, and then oleic acid was added to the solution and fully stirred to form a microemulsion; the above microemulsion was statically After 6 hours, put it into a microwave oven and heat it for 20 minutes with a power of 800 watts. The obtained product was collected, washed by deionized water and absolute ethanol for 10 times, and then dried under air atmosphere to obtain layered δ-MnO 2 nanoparticles.

Embodiment 3

[0016] (1) Weigh potassium permanganate (KMnO 4 , ≥99.5), oleic acid (C 18 h 34 o 2 , relative density: 0.891~0.896g / mL at 20°C); potassium permanganate was completely dissolved in deionized water to form a solution, and then oleic acid was added to the solution and fully stirred to form a microemulsion; the above microemulsion was statically Put it in a microwave oven for 3 hours and heat it with 800 watts for 10 minutes. The obtained product was collected, washed by deionized water and absolute ethanol for 10 times, and then dried under air atmosphere to obtain layered δ-MnO 2 nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com