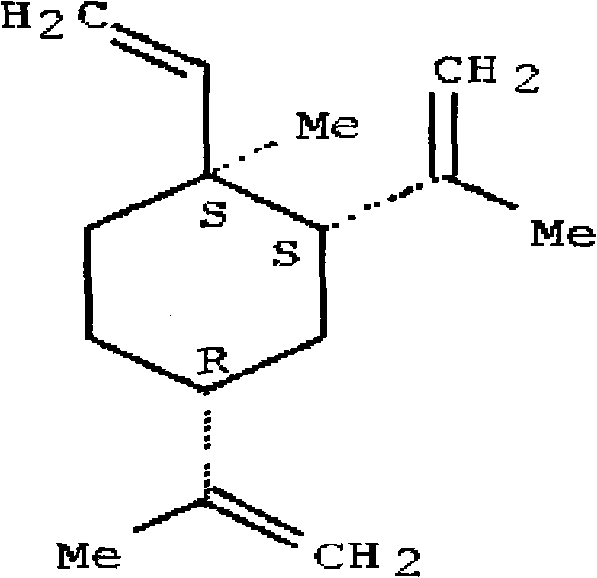

Industrial production method of high-purity beta-elemi alkene bulk medicament

A technology for elemene and raw materials, which is applied in the field of obtaining high-purity beta-elemene raw materials, can solve the problems of limited raw material sources, complicated production equipment, high cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

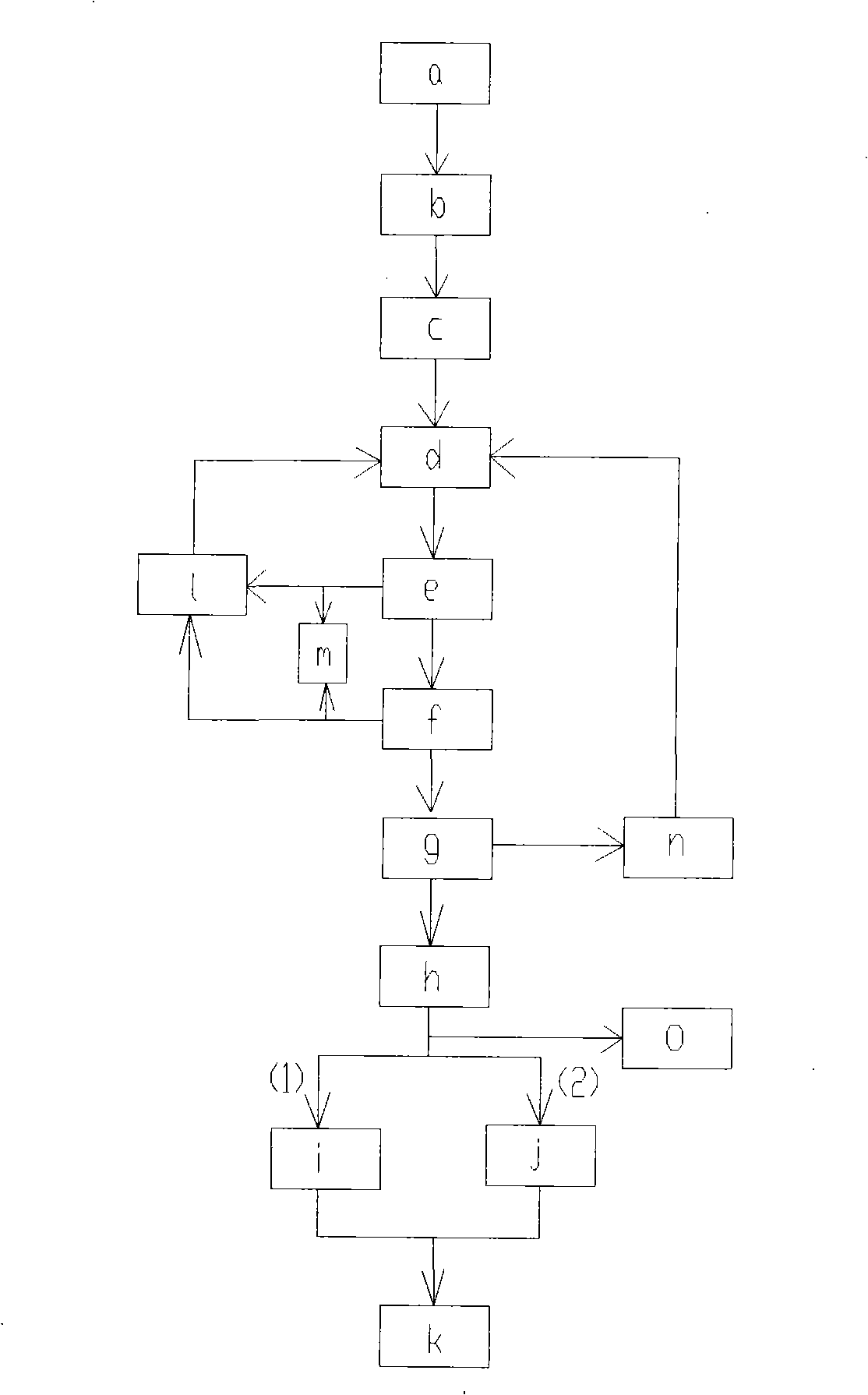

Method used

Image

Examples

Embodiment 1

[0026] a. Take natural plant medicine turmeric tuber as raw material;

[0027] b. The zedoary turmeric oil is obtained by steam distillation, and the content of β-elemene is 6.0%;

[0028] c. Put the raw material obtained in b into the rectification tower kettle for rectification, control the vacuum degree to 5-6mm Hg, the temperature of the tower kettle is 123℃~124℃, when the reflux ratio is 1:1, the removal temperature is at The impurity fraction below 75°C; the reflux ratio is controlled to be 3:1, and the fraction with a temperature of 77°C to 82°C is collected to obtain β-elemene with a content of 30.0%.

[0029] d. Dilute the 30.0% β-elemene obtained in step c with a double volume of 85% ethanol aqueous solution, and perform column chromatography on the macroporous adsorption resin. First, use a 60% ethanol aqueous solution to continuously flush the column for four If the retention volume is above, flush the column with 70% ethanol water for two retention volumes. The 70% et...

Embodiment 2

[0033] a. Take fresh leaves of natural plant Java citronella as raw materials;

[0034] b. The Java citronella, a medicinal material, is steam distilled to obtain Java volatile oil, in which the content of β-elemene is 5.0%;

[0035] c. Put the raw material obtained in b into the rectification tower kettle for rectification, control the vacuum degree to 2~3mm Hg, the temperature of the tower kettle is 116℃~117℃, when the reflux ratio is 1:1, the removal temperature is at The impurity fraction below 75°C; the reflux ratio is controlled to be 3:1, and the fraction with a temperature of 78°C to 81°C is collected to obtain β-elemene with a content of 16.0%.

[0036] d. Dilute the 16.0% β-elemene obtained in step c with a double volume of 80% ethanol aqueous solution, and perform column chromatography on a 20-fold weight macroporous adsorption resin, first with a 60% ethanol aqueous solution Continuously flush the column with more than four retention volumes, and then flush the column ...

Embodiment 3

[0040] a. Take the fresh leaves of natural plant Solidago canadensis as raw materials;

[0041] b. The volatile oil of Solidago goldenrod leaves is extracted by supercritical extraction, in which the content of β-elemene is 14.3%;

[0042] c. Put the raw material obtained in b into the rectification tower kettle for rectification, control the vacuum to be 6~7mm Hg, the temperature of the tower kettle is 123~124℃, when the reflux ratio is 1:1, the removal temperature is 75 The impurity fraction below ℃; the reflux ratio is controlled to 4:1, and the fraction with a temperature of 79℃~82℃ is collected to obtain β-elemene with a content of 40.6%.

[0043] d. Dilute the 40.6% β-elemene obtained in step c with a 90% ethanol aqueous solution twice the volume, and perform column chromatography on a 20-fold weight macroporous adsorption resin, first using a 60% ethanol aqueous solution Continuously flush the column with more than four retention volumes, and then flush the column with 75% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com