Supported rare earth ternary catalyst for combined polymerization of carbonic anhydride and epoxide and preparing method therefor

A three-way catalyst and epoxide technology, applied in the field of supported rare earth three-way catalysts, can solve the problems of complicated preparation process, no rare earth three-way catalyst, etc., and achieve the effect of increasing catalytic activity and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

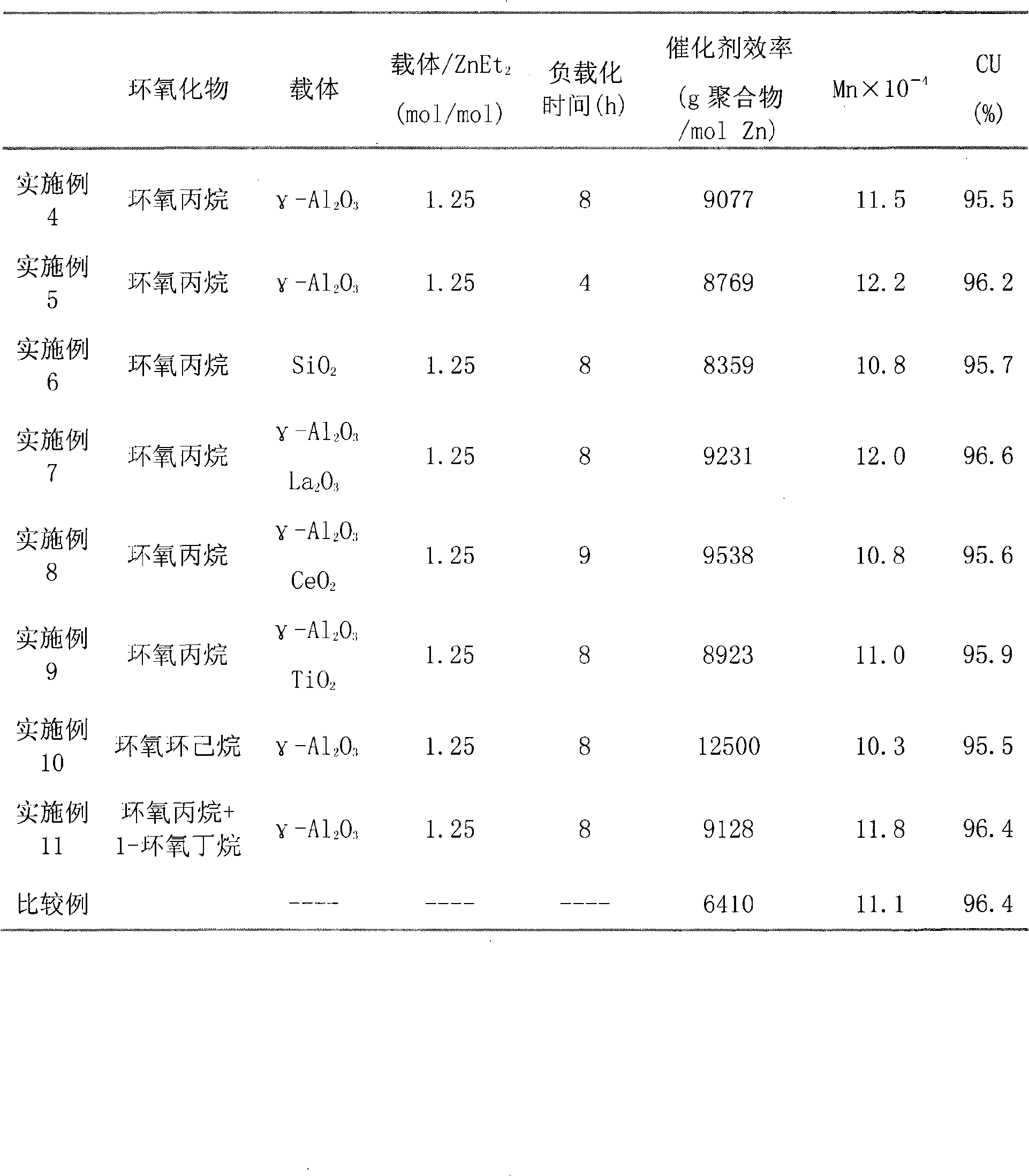

Examples

Embodiment 1

[0021] Embodiment 1 is used for the preparation of the supported rare earth three-way catalyst of carbon dioxide and epoxide copolymerization

[0022] in 99.98% pure CO 2 Under protection, add 30ml 1,3-dioxolane in the catalyst preparation bottle, then add 0.000975mol rare earth complex yttrium trichloroacetate (Y(CCl 3 COO) 3 ) and 0.00975mol glycerol, to be Y (CCl 3 COO) 3 After all dissolved, slowly drop ZnEt into the bottle 2 , ZnEt 2 It is advisable to control the reaction temperature at 35-45°C for the dropping speed; after the dropping is completed, after no gas is released, the prepared rare earth three-way catalyst is aged at 60°C for 3 hours with shaking. in CO 2 Under protection, add γ-Al activated at 600°C for 10 hours to the aged rare earth three-way catalyst 2 o 3 (50-100 nm) 0.0244 mol and 15 g of glass beads with a particle diameter of 4-6 mm, and additionally add 10 ml of 1,3-dioxa-pentane. The prepared bottle was placed in a constant temperature bath...

Embodiment 2

[0023] Embodiment 2 is used for the preparation of the supported rare earth three-way catalyst of carbon dioxide and epoxide copolymerization

[0024] in CO 2 Under protection, add γ-Al activated at 600°C for 10 hours to the aged rare earth three-way catalyst in the preparation bottle 2 o 3 (50~100nm)0.0122mol, La 2 o 3 (100-250 nm) 0.0122 mol and 15 g of glass beads with a particle diameter of 4-6 mm, and 10 ml of 1,3-dioxa-pentane was added. The prepared bottle was placed in a constant temperature bath at 60±2°C for mechanical vibration grinding for 8 hours, the vibration frequency was 180 times / min, and the amplitude was 45 mm. Other conditions are as in Example 1.

Embodiment 3

[0025] Embodiment 3 is used for the preparation of the supported rare earth three-way catalyst of carbon dioxide and epoxide copolymerization

[0026] in CO 2 Under protection, add SiO activated at 650°C for 8 hours to the aged rare earth three-way catalyst in the preparation bottle 2 (150-250 nm) 0.0244 mol and 15 g of glass beads with a particle diameter of 4-6 mm, and 10 ml of 1,3-dioxa-pentane was added. The preparation bottle was placed in a constant temperature bath at 60±2° C. for 8 hours with sealed magnetic stirring and grinding, and the magnetic stirring speed was 500 rpm. Other conditions are as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com