Special aqueous adhesive for ceramic diaphragm of lithium battery, and preparation method and application thereof

A technology of ceramic diaphragm and adhesive, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of limited use conditions and modification range, adhesive failure, emulsion structure damage, etc., and achieve good thermal stability. Mechanical stability and thermochemical stability, good dispersion and adhesiveness, good adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

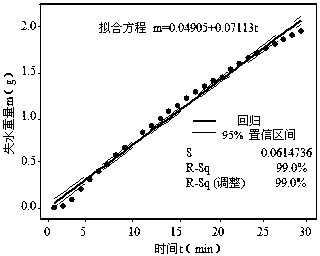

Examples

Embodiment 1

[0045]Put 30g of itaconic acid and 120g of water into the three-necked bottle equipped with a stirring device and a condenser, start stirring, and the water bath is heated to 60°C and stirred until the itaconic acid is completely dissolved. Add 30g of 2-hydroxyethyl acrylate and stir slightly to make it fully miscible with water. Weigh 0.3 g of ammonium persulfate and 0.6 g of N-methylolacrylamide, put them into a three-necked flask and stir until completely dissolved. Keep stirring, raise the reaction temperature to 75~80°C, and react for 3~4h. At this time, the viscosity of the reaction solution increased slightly, and the theoretical solid content was 33.7%. Taking a little reaction solution, the actual solid content was 31.7%, and the conversion rate was estimated to be 94%. Lower the temperature to 25~30°C, add a saturated aqueous solution of sodium hydroxide or ammonia water dropwise to the reaction liquid, adjust the pH value of the product to 5.5±0.2, and discharge af...

Embodiment 2

[0047] 120 g of pure water was put into the beaker, followed by adding 18.4 g of sodium hydroxide while stirring until a uniform solution was formed, and then allowed to cool to room temperature. Then add 30g of itaconic acid and stir until it is completely dissolved. During the dissolution process, keep a cold water bath to take away the heat released during the dissolution and neutralization process in time. Subsequently, 1.2 g of N-methylol acrylamide, 0.3 g of ammonium persulfate and 30 g of hydroxyethyl acrylate were respectively added, stirred evenly, and poured into a three-necked bottle equipped with a stirring device and a condenser. Start stirring and react at 75~80°C for 2.5~3h. Take another beaker, put in 120g of pure water and 30g of itaconic acid, heat and stir in a water bath at 60°C until completely dissolved, then dissolve in 30g of hydroxyethyl acrylate and 0.15g of ammonium persulfate. Pour the solution into a three-necked bottle, keep stirring, continue th...

Embodiment 3

[0049] Put 120g of pure water into the beaker, add sodium hydroxide and stir to dissolve to control the pH to 4.5±0.1, then put in 30g of itaconic acid and stir to dissolve, measure the pH value of the solution, and add an appropriate amount of sodium hydroxide as required to control the pH of the solution. The pH value is 4.5±0.1. Then put in 0.6g of N-methylolacrylamide, 0.3g of potassium persulfate and 30g of hydroxyethyl acrylate successively, stir evenly, pour into a three-necked bottle with a stirring device and a condenser, start stirring, and store at 75~80°C React for 3~4h, cool and collect. The product is a light yellow transparent viscous homogeneous solution with a pH value of 4.6±0.2 and a viscosity of about 20000~30000cp.

PUM

| Property | Measurement | Unit |

|---|---|---|

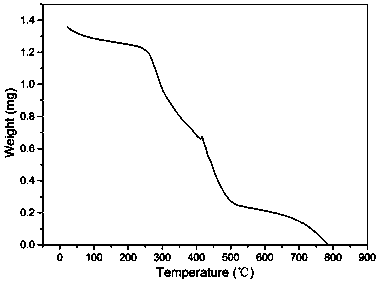

| thermal decomposition temperature | aaaaa | aaaaa |

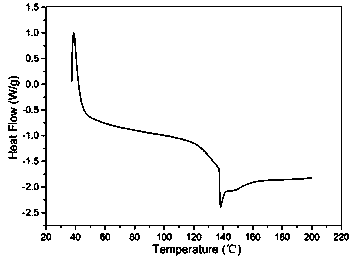

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com