Carbon electrode material of perovskite thin film solar cell and preparation method of carbon electrode material

A solar cell and carbon electrode technology, applied in the field of solar cells, can solve the problems of poor solar cell stability, unsatisfactory photoelectric conversion efficiency, and high solar cell preparation cost, and achieve good storage stability and high photoelectric conversion efficiency. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

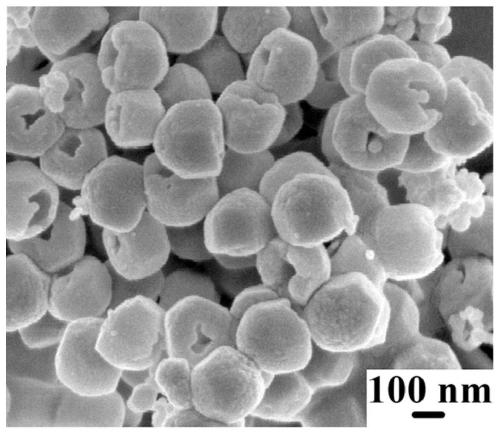

[0025] A preparation method of a carbon electrode material for a perovskite thin film solar cell, specifically comprising the following steps:

[0026] S1. Add 1g of glucose into an autoclave with 40ml ethylene glycol-water solution (the volume ratio of ethylene glycol to distilled water is 2:1), stir and dissolve to obtain carbon-ethylene diol-water solution;

[0027] S2. Add 0.2 g of cetyltrimethylammonium bromide to the carbon-ethylene glycol-water solution obtained in S1, and stir for 30 minutes to obtain a mixed solution;

[0028] S3, reacting the mixed solution obtained in S2 in an oven at 160° C. for 1 hour to obtain a reaction solution, and then filtering, washing and drying the reaction solution to obtain a reactant;

[0029] S4. Calcining the reactant obtained in S3 at 550° C. for 2 hours in a tube furnace under an argon atmosphere, and then washing, centrifuging, and drying to obtain a carbon electrode material.

Embodiment 2

[0031] A method for preparing a carbon electrode material for a perovskite thin-film solar cell. The specific steps are the same as in Example 1, except that the mass of cetyltrimethylammonium bromide used in S2 is 0.6g.

Embodiment 3

[0033] A method for preparing a carbon electrode material for a perovskite thin-film solar cell. The specific steps are the same as in Example 1, except that the mass of cetyltrimethylammonium bromide used in S2 is 1 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com