Process for producing corrosion-protection, antiscaling and wax-proof sustained-release particles for oil well

A slow-release particle, anti-scaling technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as oil well shutdown, and achieve the effects of short production cycle, adjustable formula and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

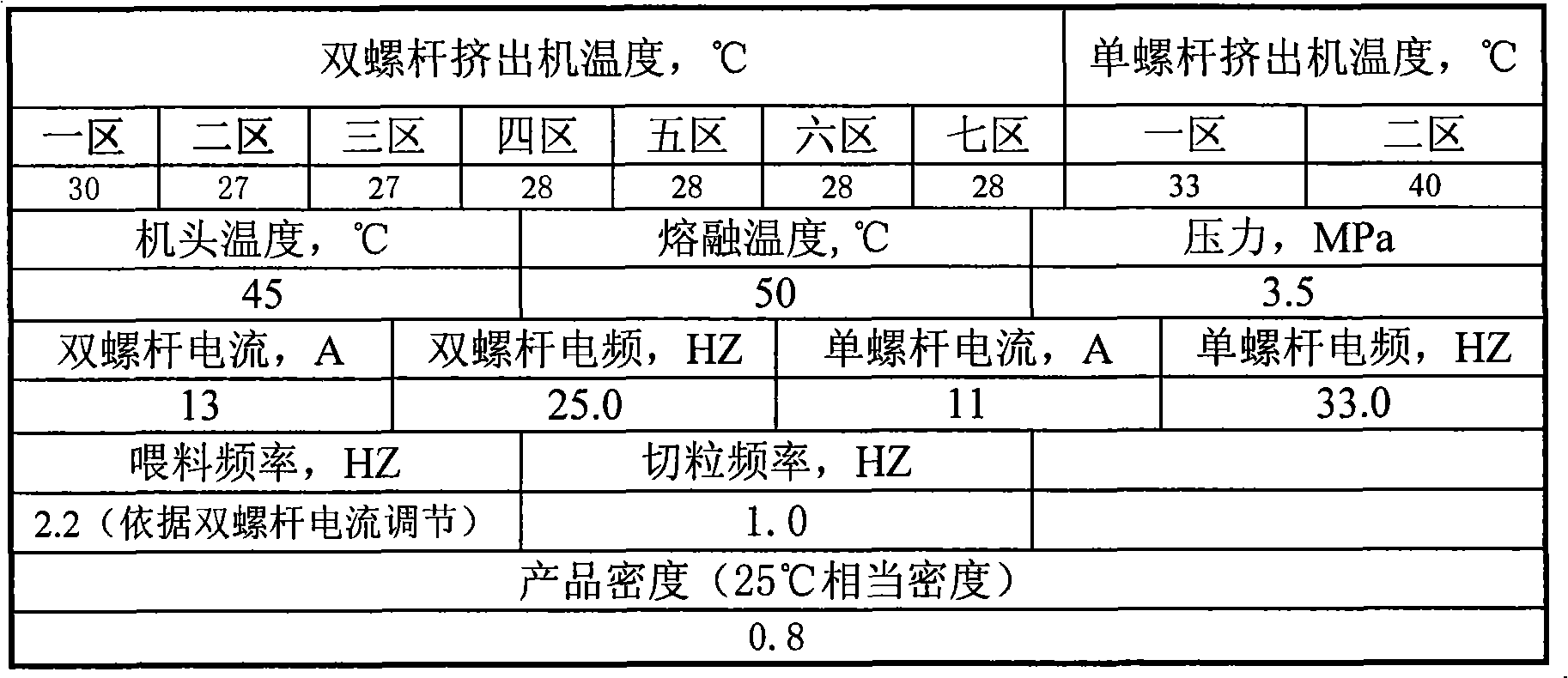

[0009] Embodiment 1, the preparation method of the present invention: start the circulating water system, preheat the machine for about 30 minutes, slowly rotate the single-screw frequency conversion adjustment knob to the specified value, then slowly rotate the twin-screw frequency conversion adjustment knob to the specified value, when the double-screw frequency conversion adjustment knob is When it reaches 13 Hz, slowly rotate the frequency conversion adjustment knob of the feeder to the specified value. Add the material into the high mixer according to the proportion of formula 1 in Table 3 and stir at room temperature for 5 minutes to mix evenly. The material is added to the twin-screw extruder through the automatic feeder for mixing, and the mixed mature material enters the single-screw extruder. Extruder, start the fan, hopper and vibrating screen after the single-screw has material, and adjust the frequency conversion of the pelletizing to 1.0, the single-screw extruder...

Embodiment 2

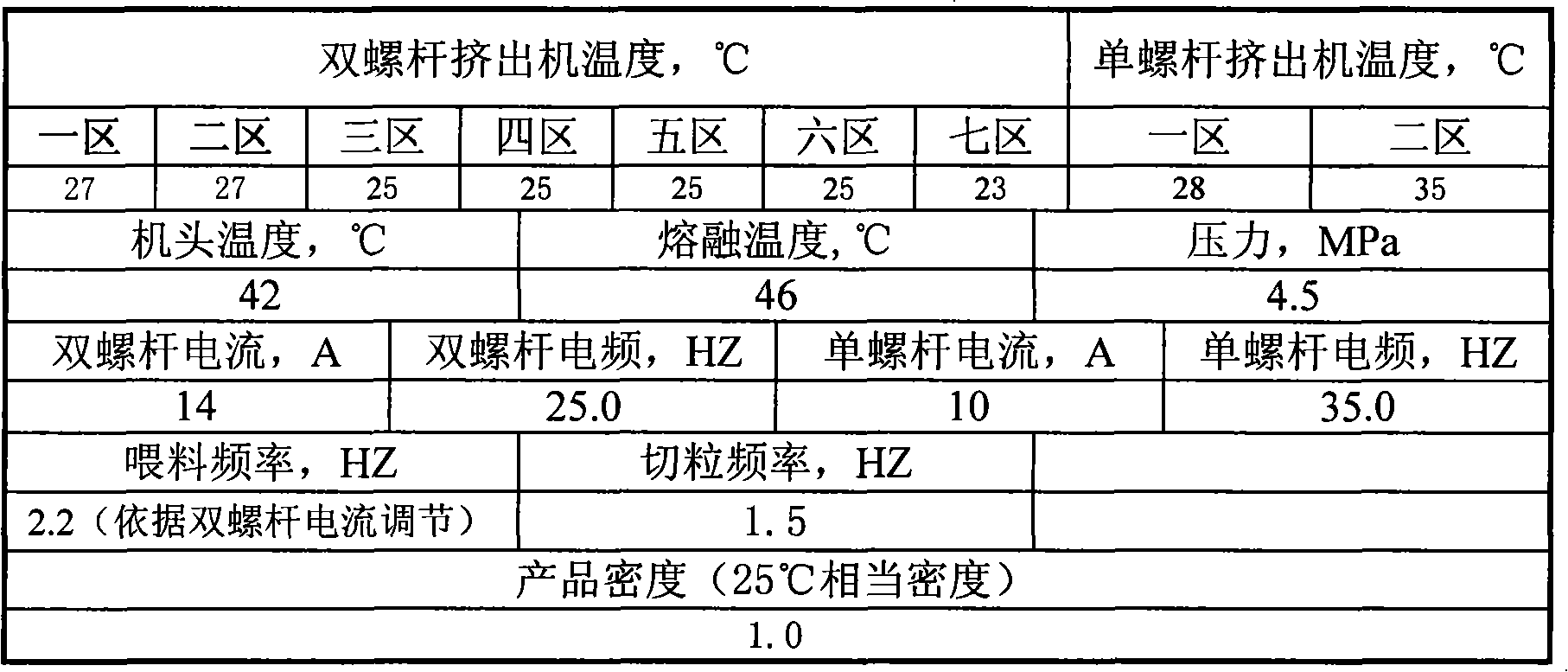

[0012] Embodiment 2, the preparation method of the present invention: start the circulating water system, preheat the machine for about 30 minutes, slowly rotate the single-screw frequency conversion adjustment knob to the specified value, then slowly rotate the twin-screw frequency conversion adjustment knob to the specified value, when the double-screw frequency conversion adjustment knob is When it reaches about 14 Hz, slowly rotate the frequency conversion adjustment knob of the feeder to the specified value. Add the material into the high mixer according to the proportion of formula 2 in Table 3 and stir at room temperature for 5 minutes to mix evenly. The material is added to the twin-screw extruder through the automatic feeder for mixing, and the mixed mature material enters the single-screw extruder. Extruder, start the fan, hopper and vibrating screen after the single-screw has material, and adjust the frequency conversion of the pelletizing to 1.0, the single-screw ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com