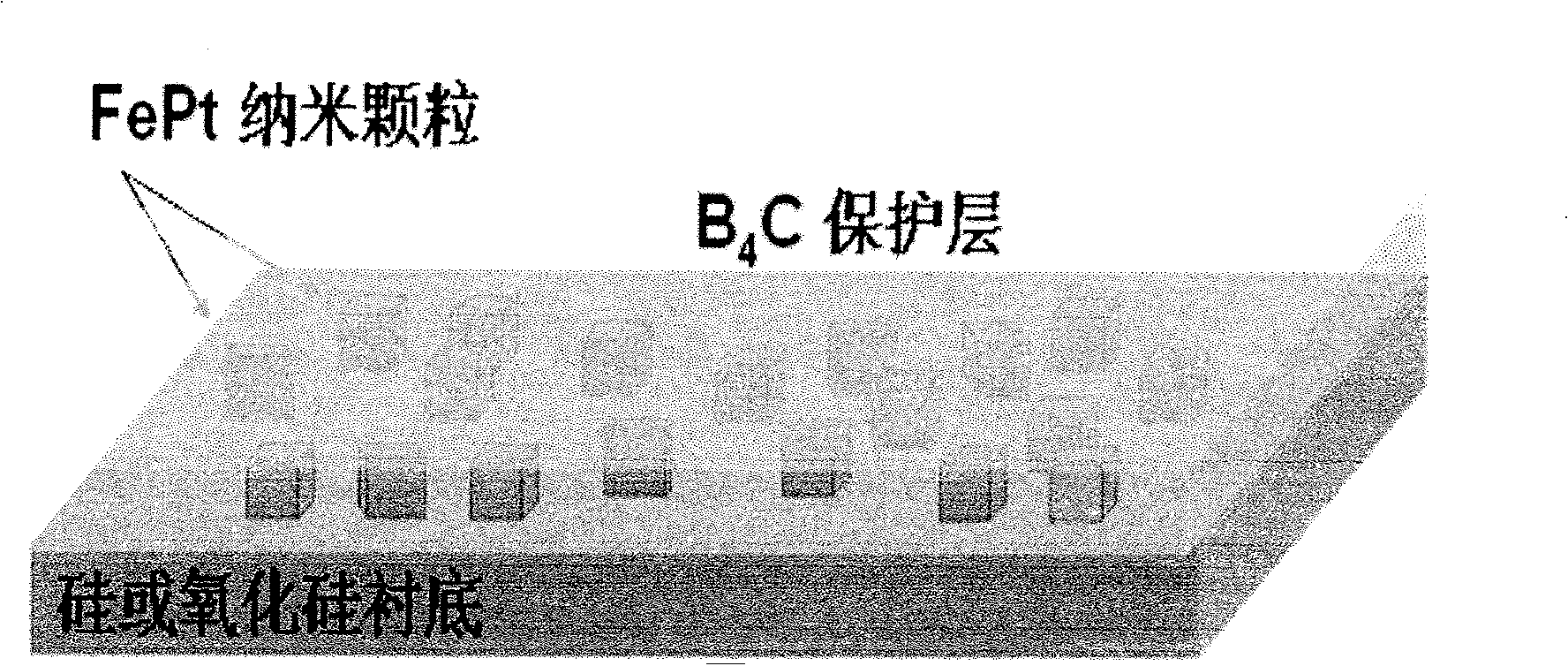

Magnetic memory material of compound structure of FePt nano-particle monolayer film and B4C and method of producing the same

A nanoparticle and single-layer film technology, which is applied in metal material coating process, coating, ion implantation plating, etc. Disappearance and other problems, to achieve high integration, improve recording density, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

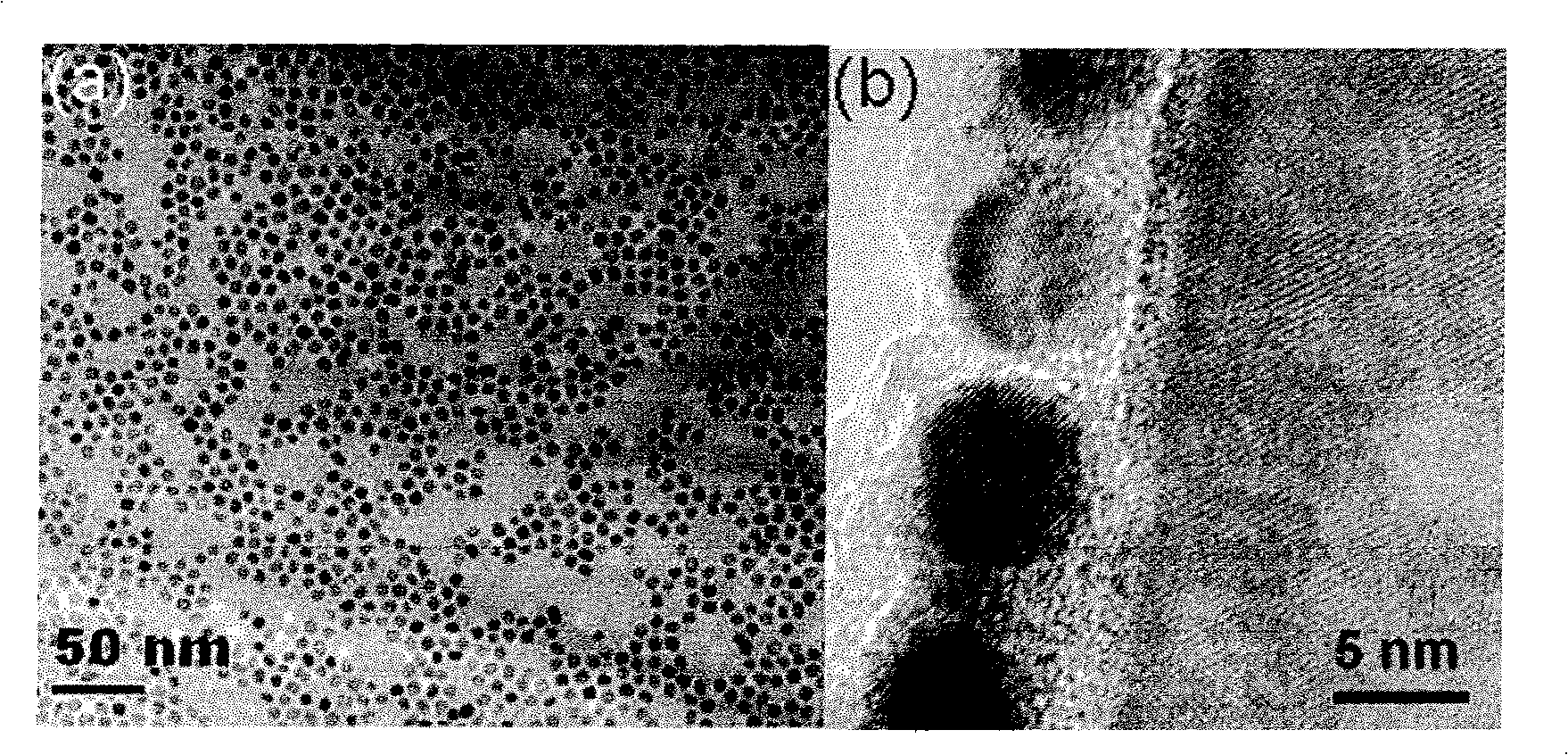

[0023] 1. 0.5 mmol of platinum acetylacetonate, 2 mmol of Fe(CO) 5 , 1 mmol of oleic acid and 1 mmol of oleylamine are mixed and dissolved in 20 milliliters of benzyl alcohol, stirred and heated under nitrogen, and the solution is heated to 200 degrees at a rate of 5 degrees per minute, and kept at this temperature for reaction Monodisperse iron-platinum nanoparticles were prepared in 2 hours.

[0024] 2. After the solution is cooled to room temperature, pour 40 ml of absolute ethanol into the solution, ultrasonically oscillate for 5 minutes, pour it into a centrifuge tube, and centrifuge at a speed of 10,000 rpm. Pour off the brown supernatant after centrifugation, and put The black precipitate in the tube was dissolved in 15 ml of hexane. Add the same volume of absolute ethanol and centrifuge under the same conditions, and dissolve the obtained black precipitate into 10 ml of hexane, then wash once with hexane and alcohol under the same conditions, and disperse the iron-pla...

Embodiment 2

[0029] 1. 0.5 mmol of platinum acetylacetonate, 2 mmol of Fe(CO) 5 , 2 millimoles of oleic acid and 2 millimoles of oleylamine are mixed and dissolved in 20 milliliters of benzyl alcohol, stirred and heated under nitrogen conditions, the solution is heated to 200 degrees at a rate of 5 degrees Celsius per minute, and this temperature is maintained for reaction Monodisperse iron-platinum nanoparticles were prepared in 2 hours.

[0030] 2. After the solution is cooled to room temperature, pour 20 ml of absolute ethanol into the solution, ultrasonically oscillate for 5 minutes, pour it into a centrifuge tube, and centrifuge at a speed of 5000 rpm, pour off the brown supernatant after centrifugation, and put The black precipitate in the tube was dissolved in 15 ml of hexane. Add the same volume of absolute ethanol and centrifuge under the same conditions, and dissolve the obtained black precipitate into 10 ml of hexane, then wash once with hexane and alcohol under the same condit...

Embodiment 3

[0035] 1. 0.5 mmol of platinum acetylacetonate, 2 mmol of Fe(CO) 5 , 4 millimoles of oleic acid and 4 millimoles of oleylamine are mixed and dissolved in 20 milliliters of benzyl alcohol, stirred and heated under nitrogen conditions, the solution is heated to 200 degrees Celsius at a rate of 5 degrees Celsius per minute, and this temperature is maintained for reaction Monodisperse iron-platinum nanoparticles were prepared in 2 hours.

[0036] 2. After the solution is cooled to room temperature, pour 30 ml of absolute ethanol into the solution, ultrasonically oscillate for 5 minutes, pour into a centrifuge tube, and centrifuge at a speed of 3000 rpm. Pour off the brown supernatant after centrifugation, and remove the black color in the tube. The precipitate was dissolved in 15 mL of hexane. Add the same volume of absolute ethanol and use the same conditions to dissolve the obtained black precipitate into 10 ml of hexane, then wash it once with hexane and alcohol under the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com