Method of preparing lithium iron phosphate having high conductivity and superior low temperature discharge property

A technology of lithium iron phosphate and high conductivity, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of poor low-temperature discharge performance and low conductivity of lithium iron phosphate, and achieve strong high-current discharge capability and enhanced Effect of low temperature discharge performance and good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

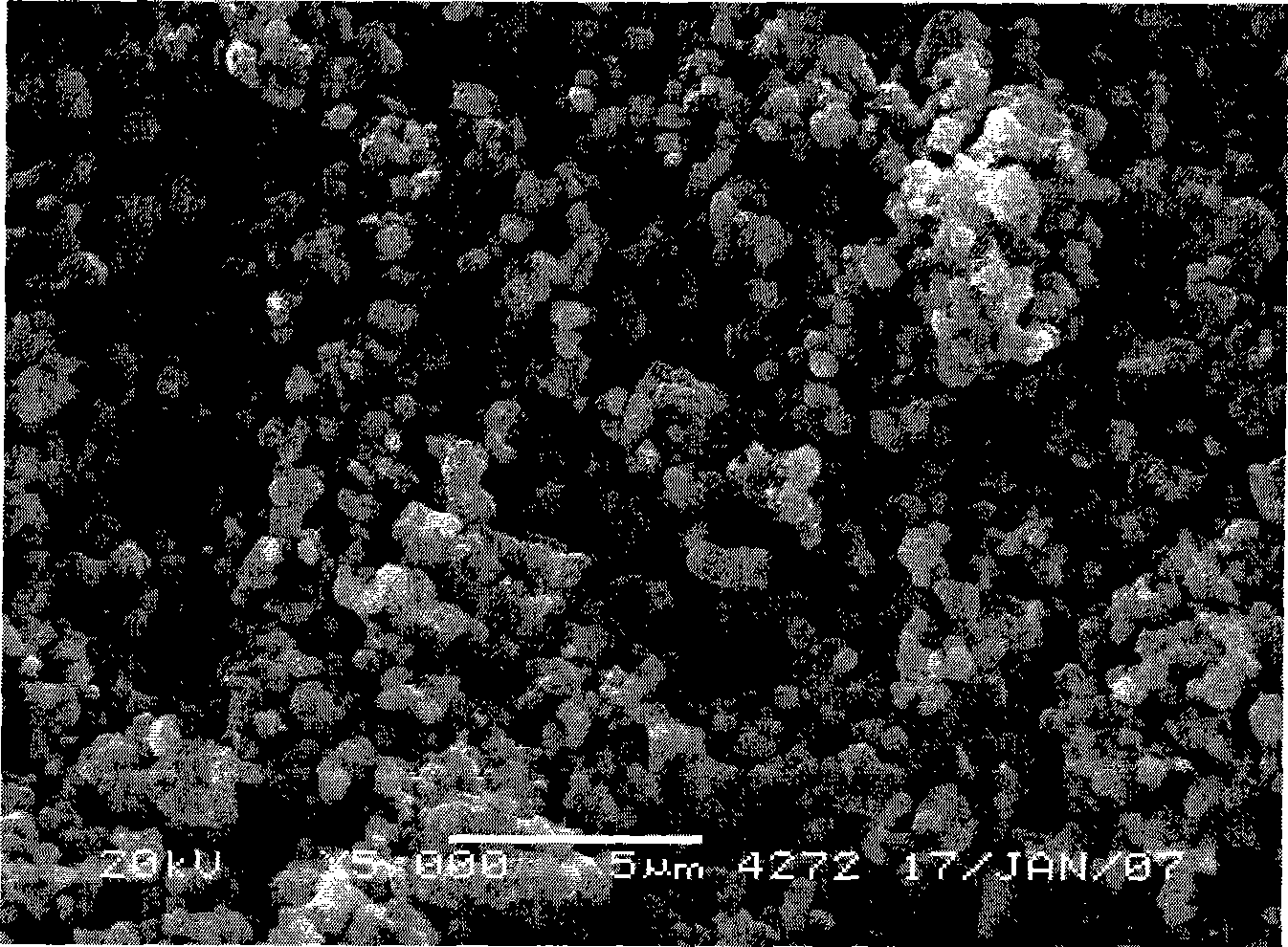

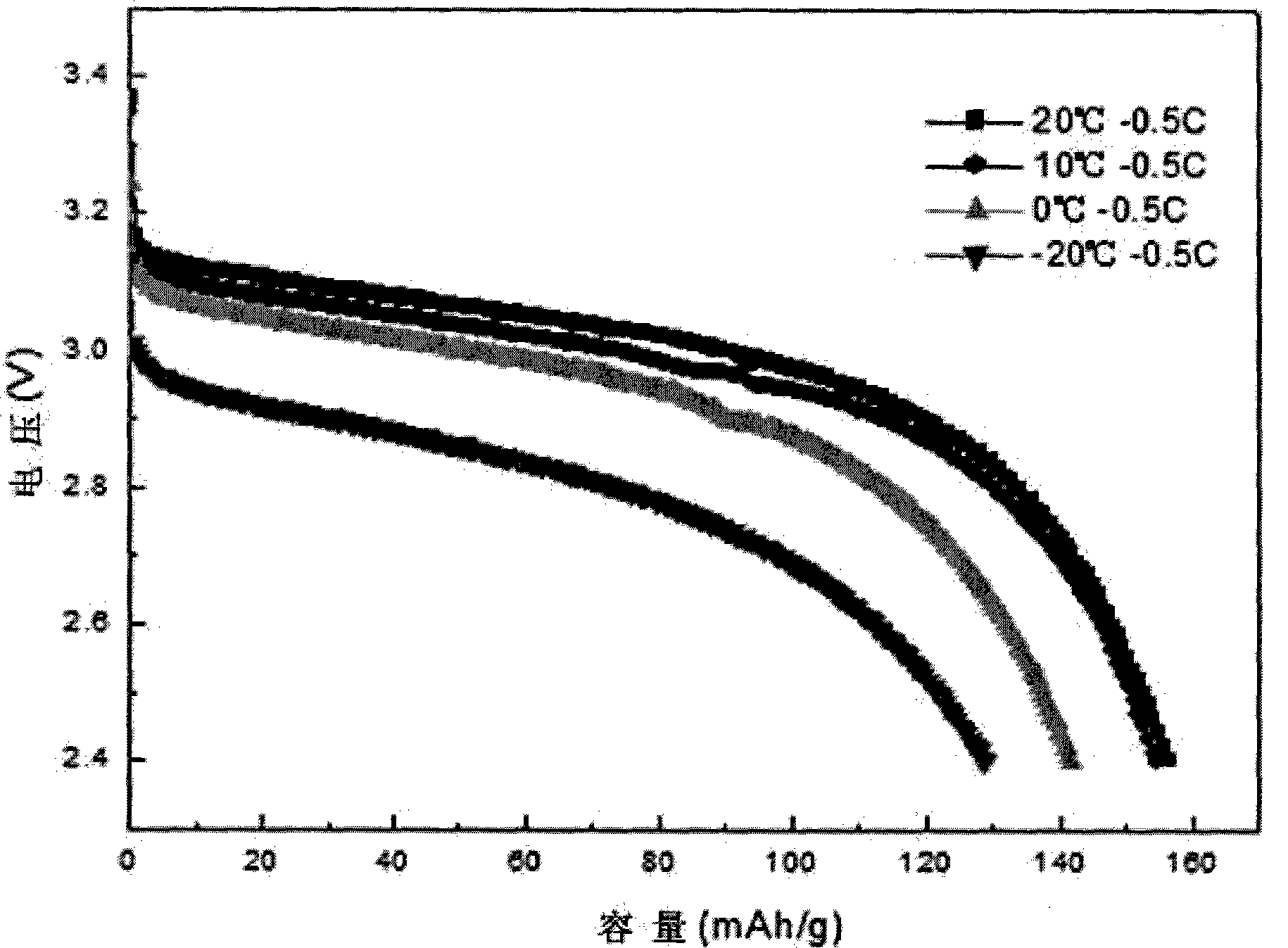

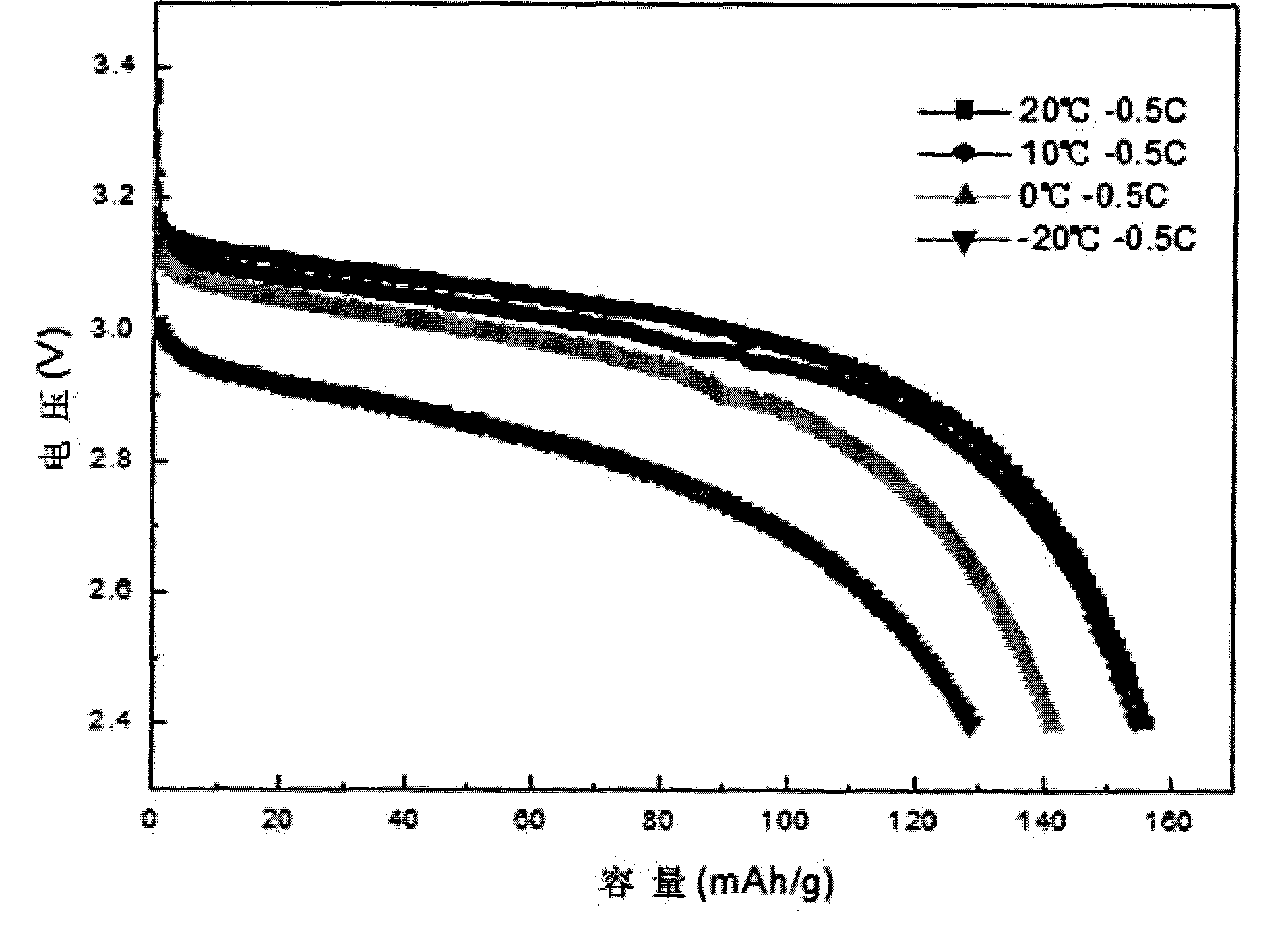

Embodiment 1

[0028] Ferrous sulfate solution with a molar concentration of iron salt of 0.1mol / L is mixed with phosphoric acid solution, the mixing condition is iron: phosphorus molar ratio 3:2.5, and then rapidly neutralized with ammonia water with a molar concentration of 0.1mol / L at a temperature of -20°C And, stir the solution during neutralization to speed up the neutralization speed, and obtain ultra-fine Fe in an instant 3 (PO 4 ) 2 ·xH 2 O precipitation, ultrafine Fe 3 (PO 4 ) 2 ·xH 2 O precipitate particle size D 50 At 4 μm, the Fe 3 (PO 4 ) 2 ·xH 2 The O precipitate was washed and dried under vacuum, then mixed with Fe at a molar ratio of 1:1:0.1 3 (PO 4 ) 2 ·xH 2 O, lithium phosphate, conductive agent, the conductive agent is sucrose, mixed evenly, and sintered at 550°C for 20 hours to obtain lithium iron phosphate material, the particle size of lithium phosphate used in sintering is D 50 at 1 μm.

Embodiment 2

[0030] Ferrous sulfate solution with a molar concentration of iron salt of 0.25mol / L is mixed with phosphoric acid solution, the mixing condition is iron:phosphorus molar ratio 3:2.4, and then rapidly neutralized with ammonia water with a molar concentration of 0.5mol / L at a temperature of -10°C And, stir the solution during neutralization to speed up the neutralization speed, and obtain ultra-fine Fe in an instant 3 (PO 4 ) 2 ·xH 2 O precipitation, ultrafine Fe 3 (PO 4 ) 2 ·xH 2 O precipitate particle size D 50 At 3 μm, the Fe 3 (PO 4 ) 2 ·xH 2 The O precipitate was vacuum-dried and then mixed with Fe at a molar ratio of 1:1:0.1 3 (PO 4 ) 2 ·xH 2 O, lithium phosphate, conductive agent, the conductive agent is glucose, mixed evenly, and sintered at 600°C for 10 hours to obtain lithium iron phosphate material, the particle size of lithium phosphate used in sintering is D 50 at 5 μm.

Embodiment 3

[0032] Ferrous sulfate solution with a molar concentration of iron salt of 0.5mol / L is mixed with phosphoric acid solution, the mixing condition is iron: phosphorus molar ratio 3:2.3, and then at a temperature of 0°C, the sodium hydroxide solution with a molar concentration of 1mol / L is rapidly Neutralize, stir the solution during neutralization to speed up the neutralization speed, and obtain ultra-fine Fe in an instant 3 (PO 4 ) 2 ·xH 2 O precipitation, ultrafine Fe 3 (PO 4 ) 2 ·xH 2 O precipitate particle size D 50 At 5 μm, the Fe 3 (PO 4 ) 2 ·xH 2 The O precipitate was vacuum-dried and then mixed with Fe at a molar ratio of 1:1:0.1 3 (PO 4 ) 2 ·xH 2 O, lithium phosphate, conductive agent, the conductive agent is sucrose, mixed evenly, and sintered at 650°C for 5 hours to obtain lithium iron phosphate material, the particle size of lithium phosphate used in sintering is D 50at 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com