Inductance coupling coil and inductance coupling plasma apparatus

An inductively coupled coil and plasma technology, applied to coils, circuits, electrical components, etc., can solve problems affecting the quality and stability of semiconductor processing, substrate film deposition or etching rate and uneven thickness, etc., to achieve power The effect of high coupling efficiency, good uniformity and sufficient surface modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

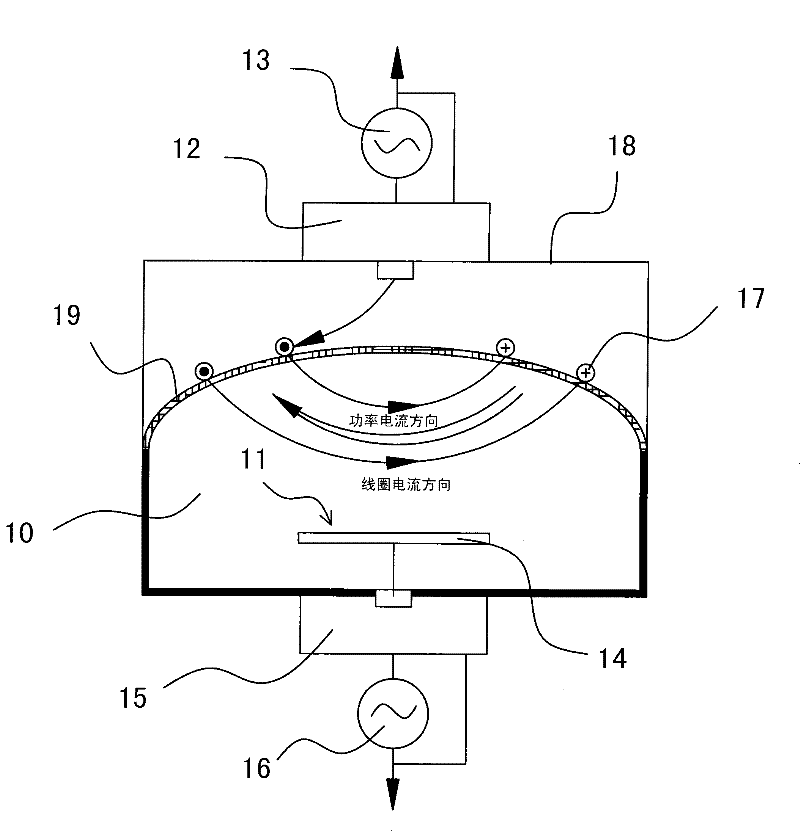

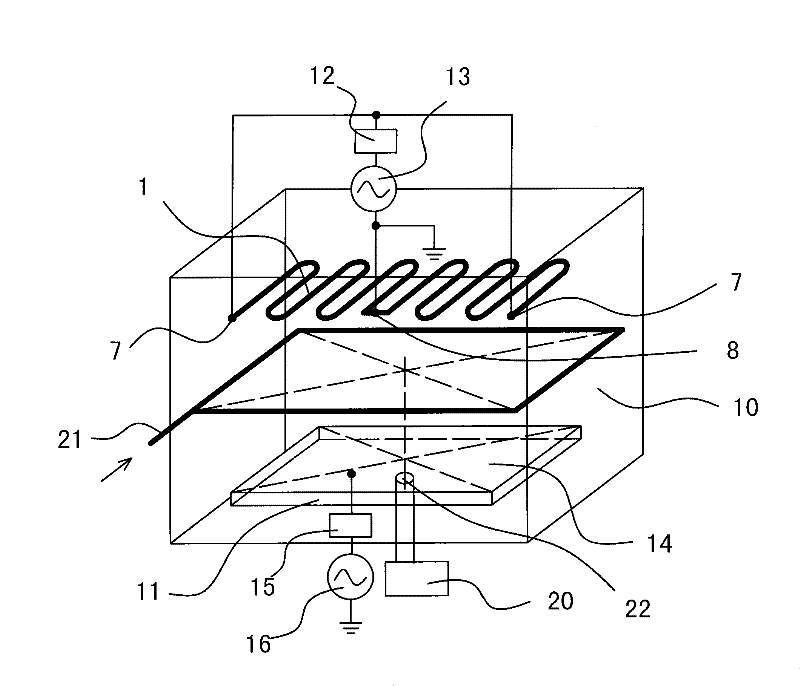

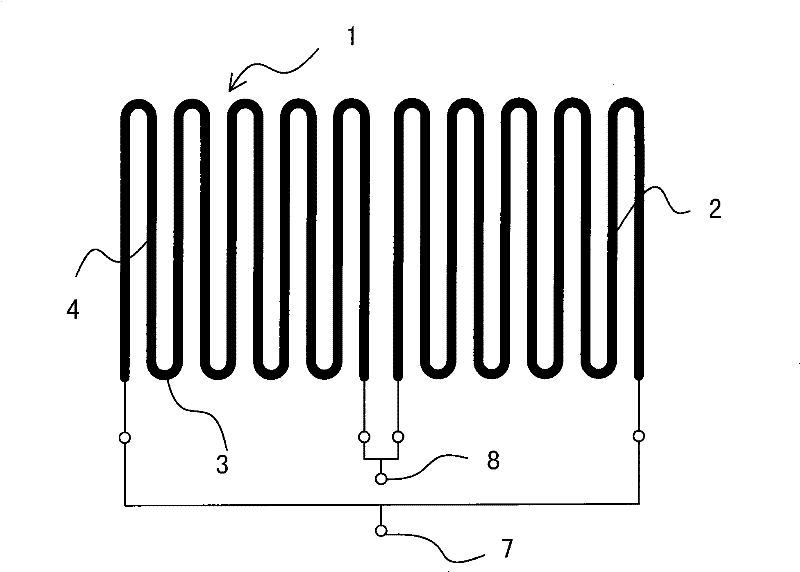

[0030] Embodiment: A kind of inductively coupled plasma device (including inductively coupled coil)

[0031] Such as figure 2 As shown, the device is mainly composed of a reaction chamber 10, a workbench 11, an inductive radio frequency generator, a substrate radio frequency generator, a gas supply system and an exhaust system. Among them, the inductive RF generator is composed of an inductive coupling coil, an inductive RF matcher 12 and an inductive RF power supply 13 , and the substrate RF generator is composed of a substrate electrode 14 , a substrate RF matcher 15 and a substrate bias power supply 16 .

[0032]Reaction chamber 10 forms a processing space by shell, and workbench 11, inductively coupled coil and substrate electrode 14 are all arranged in reaction chamber 10, and wherein, workbench 11 is positioned at the bottom of reaction chamber 10 processing spaces and is used for installing processed substrate , the inductive coupling coil is located above the workben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com