Bright pigment with gold tone, and cosmetic, paint, ink or resin composition containing the same

A bright pigment, golden tone technology, applied in the fields of cosmetics, coatings, inks and resin compositions, can solve the problems of unavailability, expensive bright pigments, limited use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

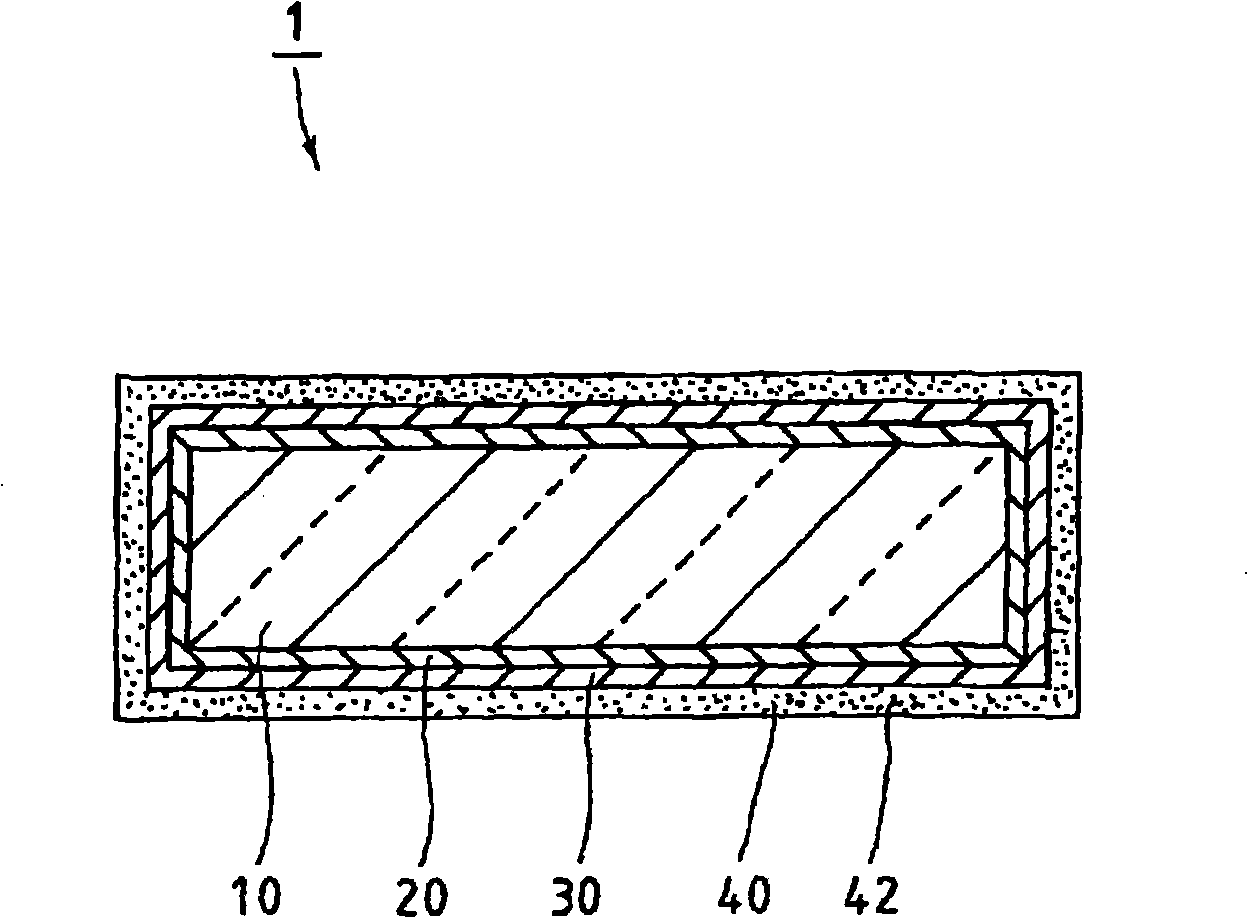

[0101] The bright pigment of embodiment 1 is as figure 1 As shown in the example of , the scaly glass substrate has a structure in which a base coating (silver coating), a gold coating, and a yellow coating are sequentially coated. The base material constituting the yellow coating is made of silica. The bright pigment of Example 1 was prepared as follows.

[0102] (Scaly glass substrate coated with silver coating)

[0103] First, MC2080PS manufactured by Nippon Sheet Glass Co., Ltd. was prepared as a scaly glass substrate coated with a silver coating. The flaky glass substrate has a structure coated with a silver film (thickness: 20 to 100 nm) by an electroless plating method.

[0104] (Formation of gold film)

[0105] The gold coating was formed by the electroless plating method as shown below. First, 6 g of sodium L-ascorbate as a reducing agent and 3 g of disodium hydrogenphosphate as a pH adjuster were added to 300 mL of pure water, and these were heated to 60° C. whi...

Embodiment 2

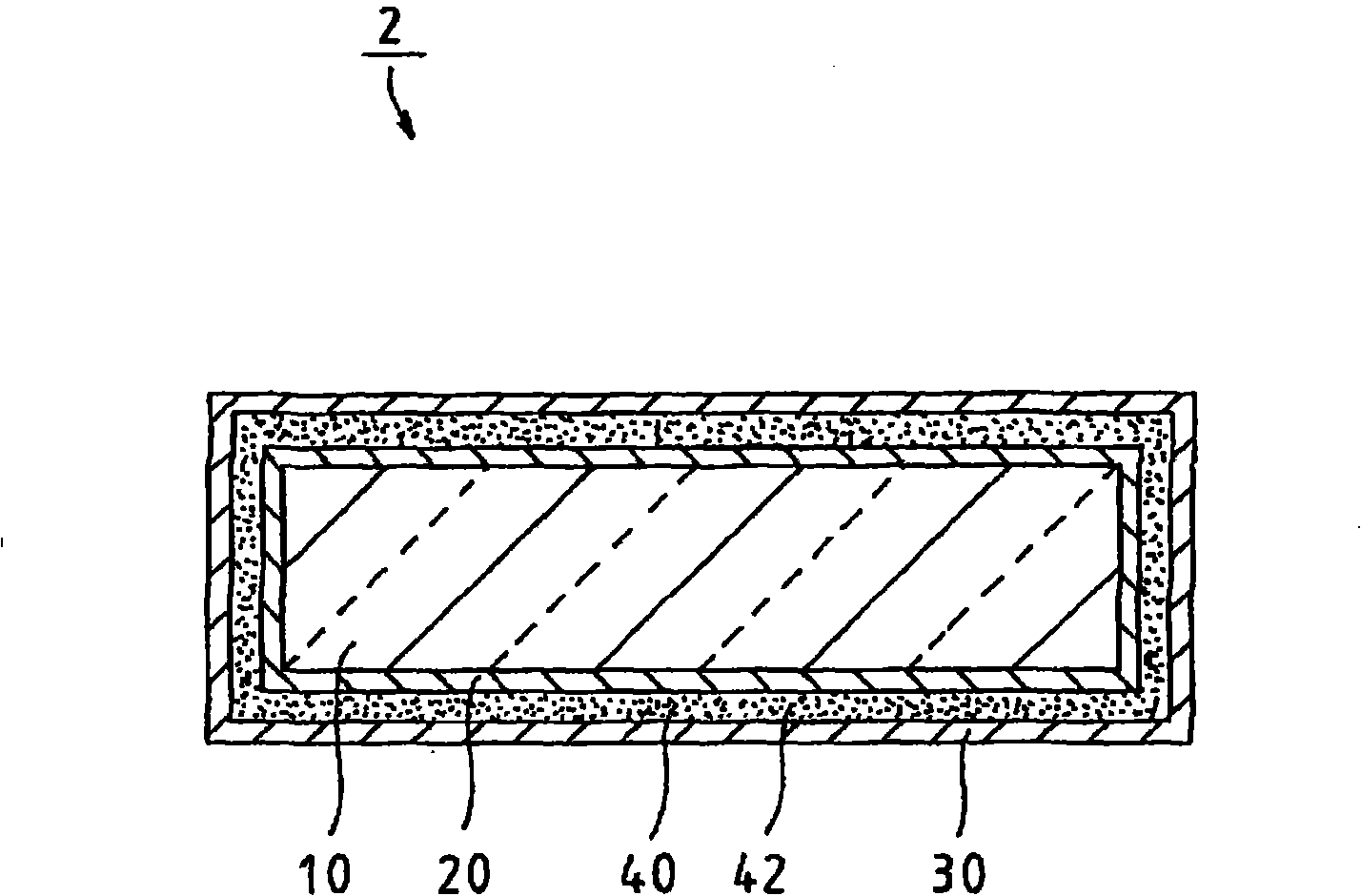

[0114] The bright pigment of embodiment 2 is as figure 2 As shown in the example of , the scaly glass substrate has a structure in which a base coating (silver coating), a yellow coating, and a gold coating are sequentially coated. MC2080PS was used in the same manner as in Example 1 for the scaly glass substrate covered with the silver coating. The method of forming the silica coating and the gold coating in which the yellow pigment is dispersed is the same as that in Example 1.

Embodiment 3

[0116] The bright pigment of embodiment 3 is as figure 1 As shown in the example of , the scaly glass substrate has a structure in which a base coating (silver coating), a gold coating, and a yellow coating are sequentially coated. The bright pigment of Example 3 was the same as the bright pigment of Example 1 except that a water-soluble yellow dye was used as the yellow pigment contained in the yellow coating, and aluminum hydroxide was used as the base material constituting the yellow coating.

[0117]First, as in Example 1, MC2080PS manufactured by Nippon Sheet Glass Co., Ltd. was used as a scaly glass substrate coated with a silver film, and gold particles with an average thickness of 1.4 nm were formed on the silver film by an electroless plating reaction. lamination. Next, after repeating filtration and water washing several times, the scaly glass substrate coated with the silver coating and the gold coating was heat-treated at 180° C. for 2 hours to be dried. The scal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com