High-curie point lead-free PTC thermal sensitive ceramic resistor material

A technology of heat-sensitive ceramics and resistance materials, applied in the field of PTC thermistor materials, can solve the problems of few reports on the results of heat-sensitive ceramic temperature control materials, and achieve the effect of avoiding the harm of lead to the environment and human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]This example presses molecular formula (Bi 1 / 2 K 1 / 2 ) Ti 1-x Ce x Sb y o 3 Dosing was performed where x = 0.2, y = 0.003. The initial raw material is selected from Bi 2 o 3 、K 2 CO 3 , tetra-n-butyl titanate [CH 3 (CH 2 ) 3 O] 4 Ti, CeO 2 , Sb 2 o 3 . Materials were prepared according to the following experimental process steps:

[0023] ①Press the initial raw material to Bi 0.5 K 0.5 Ti 0.797 Ce 0.2 Sb 0.003 o 3 Formula ingredients, weighing 46.64g Bi 2 o 3 , 13.83g K 2 CO 3 , 25.32g[CH 3 (CH 2 ) 3 O] 4 Ti, 13.78g CeO 2 , 0.175g Sb 2 o 3 ;

[0024] ②Weigh the Bi weighed in the previous step 2 o 3 and K 2 CO 3 Dissolve in dilute nitric acid; the [CH 3 (CH 2 ) 3 O] 4 Ti was dissolved in absolute ethanol; the CeO weighed in the previous step 2 and Sb 2 o 3 Dissolve in the mixed solution of nitric acid and hydrogen peroxide;

[0025] ③Mix the three mixed solutions prepared in the previous step, and use a magnetic stirring heate...

Embodiment 2

[0033] This example presses molecular formula (Bi 1 / 2 K 1 / 2 ) Ti 1-x Ce x Sb y o 3 Dosing was performed where x = 0.35, y = 0.0026. The initial raw material is selected from Bi 2 o 3 、K 2 CO 3 、[CH 3 (CH 2 ) 3 O] 4 Ti, CeO 2 , Sb 2 o 3 . Materials were prepared according to the following experimental process steps:

[0034] ①Press the initial raw material to Bi 0.5 K 0.5 Ti 0.65 Ce 0.35 Sb 0.0026 o 3 Formula ingredients, weighing 53.86gBi 2 o 3 , 15.97g K 2 CO 3 , 102.14g[CH 3 (CH 2 ) 3 O] 4 Ti, 27.85g CeO 2 , 0.17g Sb 2 o 3 ;

[0035] ②The preparation process is the same as the steps ②~⑧ in Example 1.

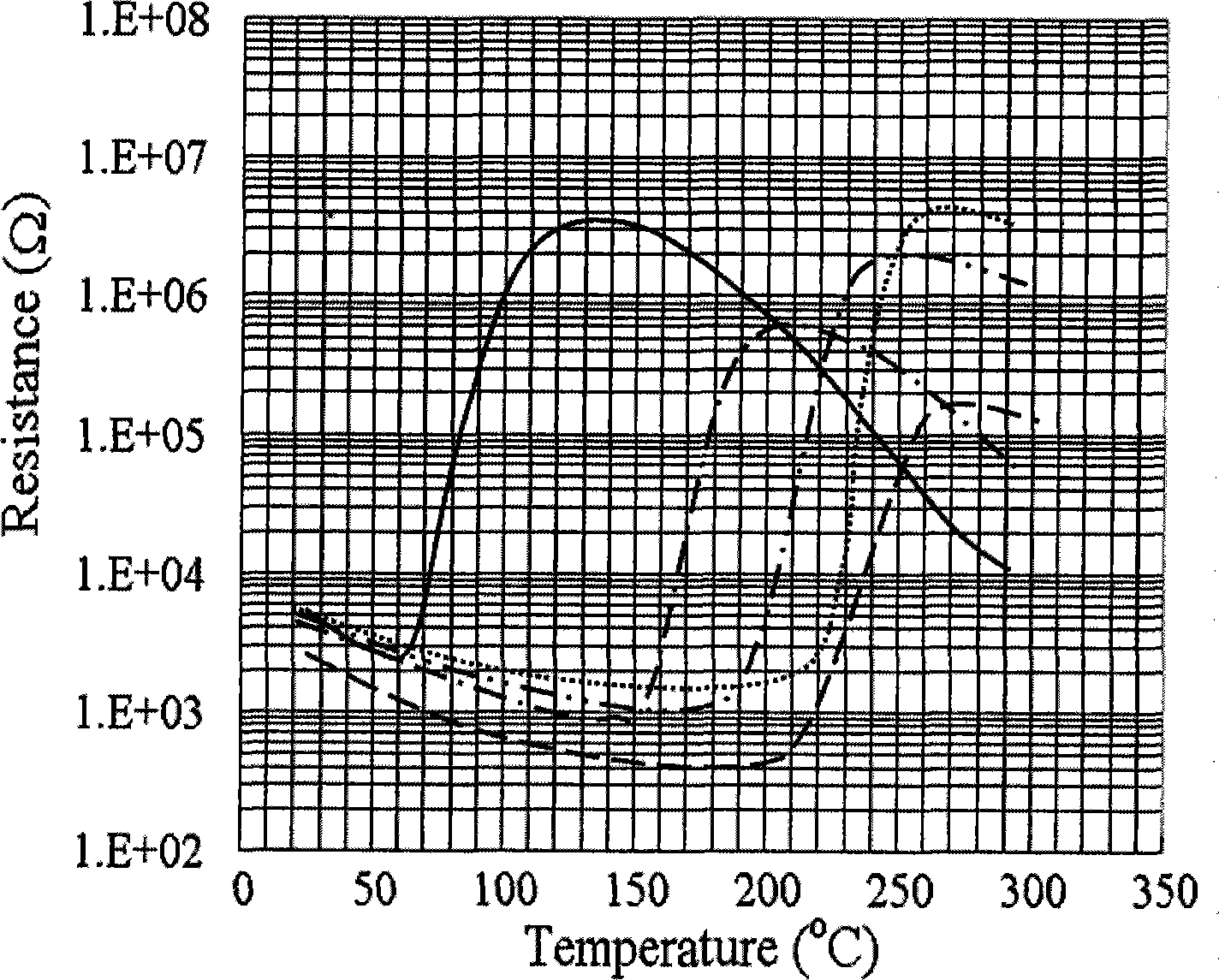

[0036] Prepared material properties are shown in Table 1 and figure 1 shown.

Embodiment 3

[0038] This example presses molecular formula (Bi 1 / 2 K 1 / 2 ) Ti 1-x Ce x Sb y o 3 Dosing was performed where x = 0.45, y = 0.0026. The initial raw material is selected from Bi 2 o 3 、K 2 CO 3 、[CH 3 (CH 2 ) 3 O] 4 Ti, CeO 2 , Sb 2 o 3 . Materials were prepared according to the following experimental process steps:

[0039] ①Press the initial raw material to Bi 0.5 K 0.5 Ti 0.55 Ce 0.45 Sb 0.0026 o 3 Formula ingredients, weighing 56.03g Bi 2 o 3 , 16.62g K 2 CO 3 , 89.92g[CH 3 (CH 2 ) 3 O] 4 Ti, 37.26g CeO 2 , 0.18g Sb 2 o 3 ;

[0040] ②The preparation process is the same as the steps ②~⑧ in Example 1.

[0041] Prepared material properties are shown in Table 1 and figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com