Bacillus licheniformis and use thereof

A technology of Bacillus licheniformis and bacterial agents, applied in the direction of bacteria, mining fluids, microorganisms, etc., can solve problems such as no research rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

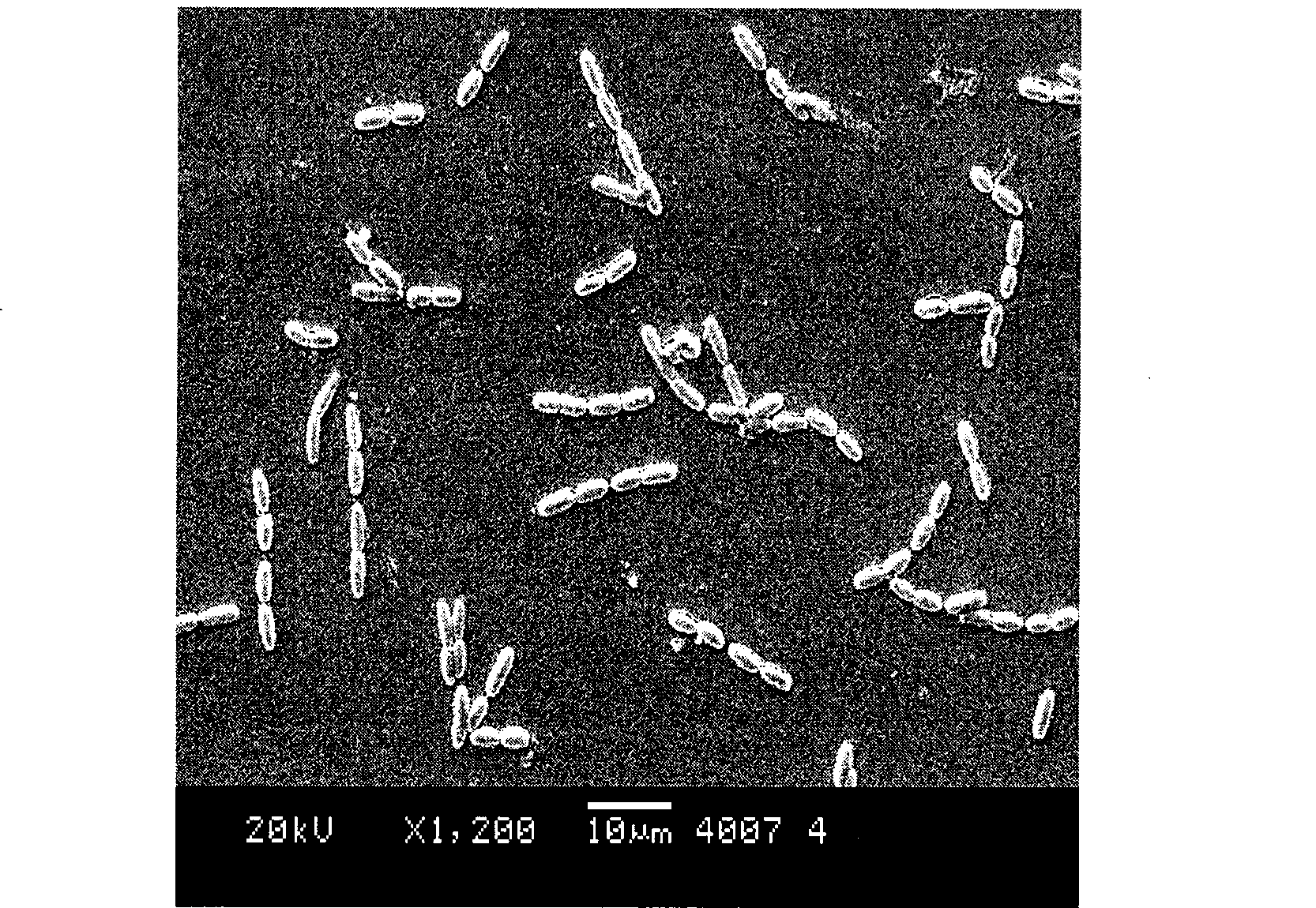

[0038] Example 1. Screening, cultivation and preservation of Bacillus licheniformis U1-3 CGMCC No. 2437

[0039] Bacterial enrichment medium: K 2 HPO 4 0.1-0.5%, NaH 2 PO 4 0.1-0.5%, (NH 4 ) 2 SO 4 0.05-0.2%, MgSO 4 ·7H 2 O 0.01-0.5%, FeCl 2 0.001-0.01%, CaCl 2 0.001-0.01%, yeast extract powder 0.02-0.2%, crude oil 1-10%, polymer (molecular weight 15 million) 0.05-0.1%; pH 6.8-7.5 121°C, sterilization 15-20min. Cultivate for 5-7 days on a shaker at 120 rpm at 45°C.

[0040] Oil plate medium: K 2 HPO 4 0.1-0.5%, KH 2 PO 4 0.1-0.5%, NH 4 NO 3 0.1-0.2%, MgSO 4 ·7H 2 O0.01-0.1%, FeSO 4 0.001-0.01%, CaCl 2 0.001-0.01%, ZnSO 4 0.01-0.02%, CuSO 4 , 0.0005-0.001%, urea 0.01-0.1%, yeast extract powder 0.02-0.2%, crude oil 1-10%, polymer (molecular weight 15 million) 0.05-0.1%, agar 1.5-2%, pH 6.8-7.5, Sterilize at 121°C for 15-20min.

[0041] Slant medium: peptone 1%, beef extract 0.3%, sodium oxide 0.5%, the rest is water, pH 7.2.

[0042] The strains to be screened must not only adapt to...

Embodiment 2

[0048] Example 2. Performance evaluation of Bacillus licheniformis U1-3 CGMCC No. 2437

[0049] The performance of Bacillus licheniformis U1-3CGMCC No. 2437 obtained in Example 1 was evaluated from the following aspects:

[0050] 1. Determination of the surface activity of the fermentation broth

[0051] The oil discharge activity of the biosurfactant produced by Bacillus licheniformis U1-3 CGMCC No. 2437 was determined by the following method: Take a petri dish, add water, and add 0.1-0.2 mL of n-alkanes on the water to form an oil film (Carry out at 45°C), and then add the fermentation broth obtained in step 2 of Example 1 to the center of the oil film. Results The center oil film was squeezed around to form a circle. The diameter of the circle was proportional to the content and activity of the surfactant. The diameter of the circle produced by the strain was measured to be greater than 3cm, indicating that Bacillus licheniformis U1-3 CGMCC No. 2437 fermentation broth has high ...

Embodiment 3

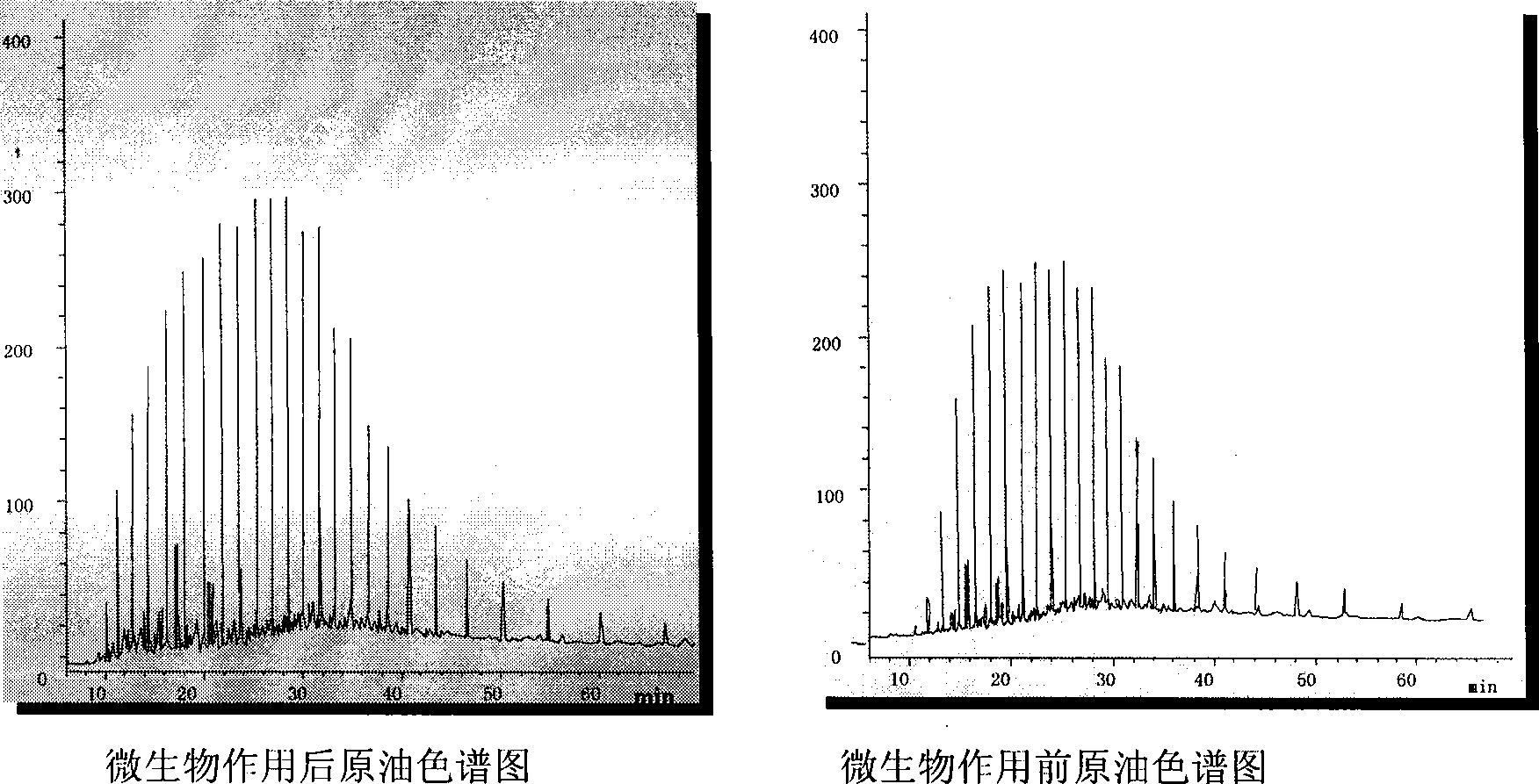

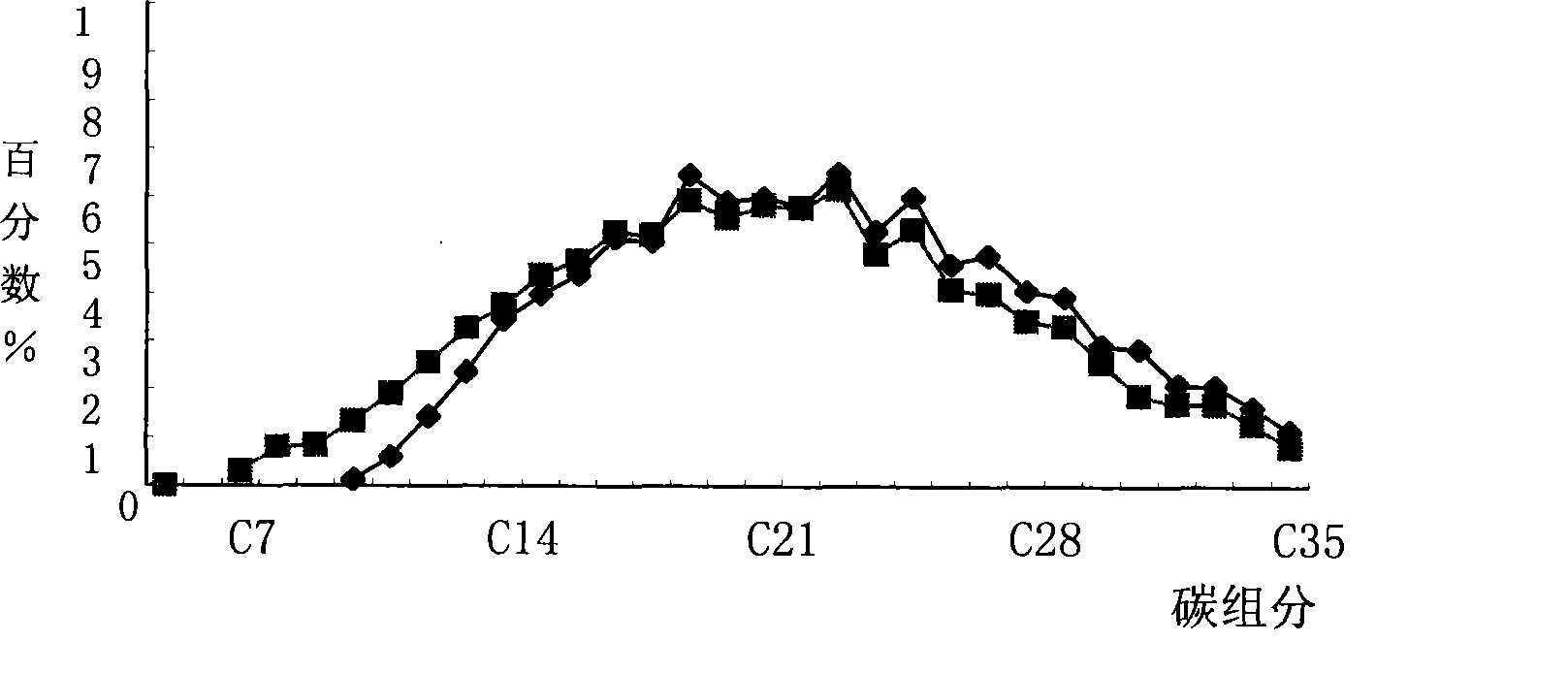

[0058] Example 3. The effect of Bacillus licheniformis U1-3 CGMCC No. 2437 on the alkane composition of crude oil

[0059] To detect the effect of Bacillus licheniformis U1-3 CGMCC No. 2437 on the alkane composition of crude oil, the method is as follows: first take a 250mL Erlenmeyer flask, add 5-10g of oil sample, Bacillus licheniformis U1-3 CGMCC No. 2437 Bacteria liquid 10mL (bacteria content>10 7 cfu / mL) and 150mL of enriched culture solution, shake culture at 45-50℃ and 150rpm for 7-15 days. After the culture is completed, collect the fermentation broth, centrifuge at 3500rpm for 15min to dehydrate, and use the full hydrocarbon chromatography analysis method (The People’s Republic of China) Natural gas industry standard SY / T5779-1995 Crude Oil Total Hydrocarbon Gas Chromatography Analysis Method) The crude oil before and after Bacillus licheniformis U1-3CGMCC No. 2437 is subjected to total hydrocarbon chromatographic analysis (3 parallel detections).

[0060] The result is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com