Preparation method of a special composite structure riser for low pressure casting

A composite structure and low-pressure casting technology, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., to achieve the effects of good thermal shock resistance, saving production costs, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

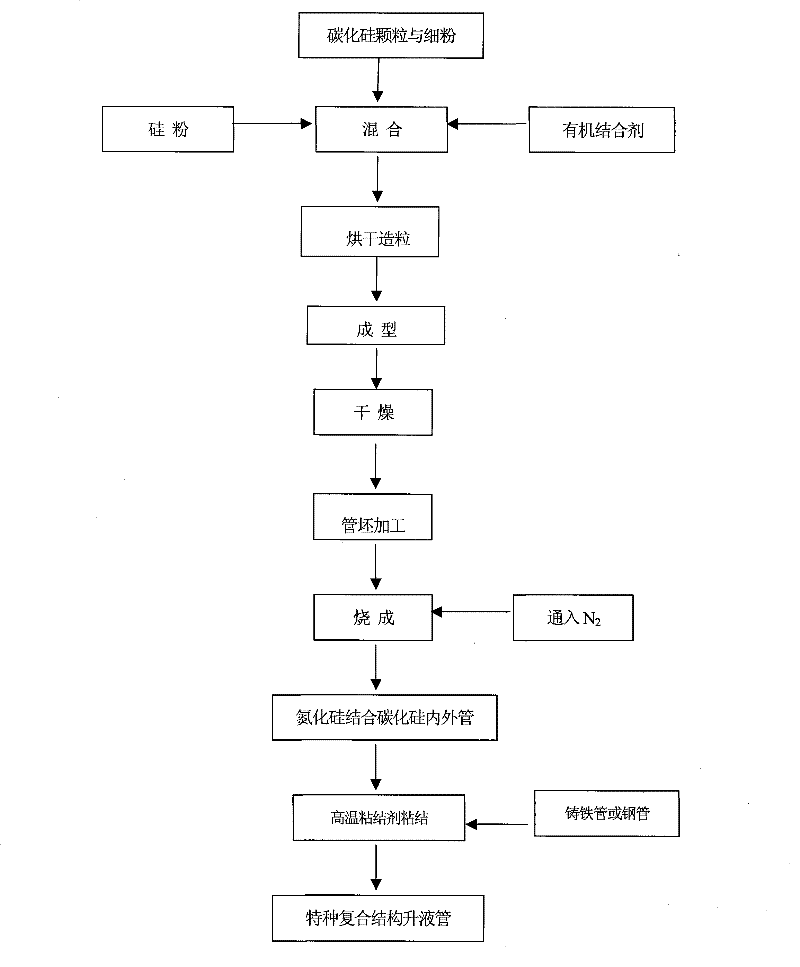

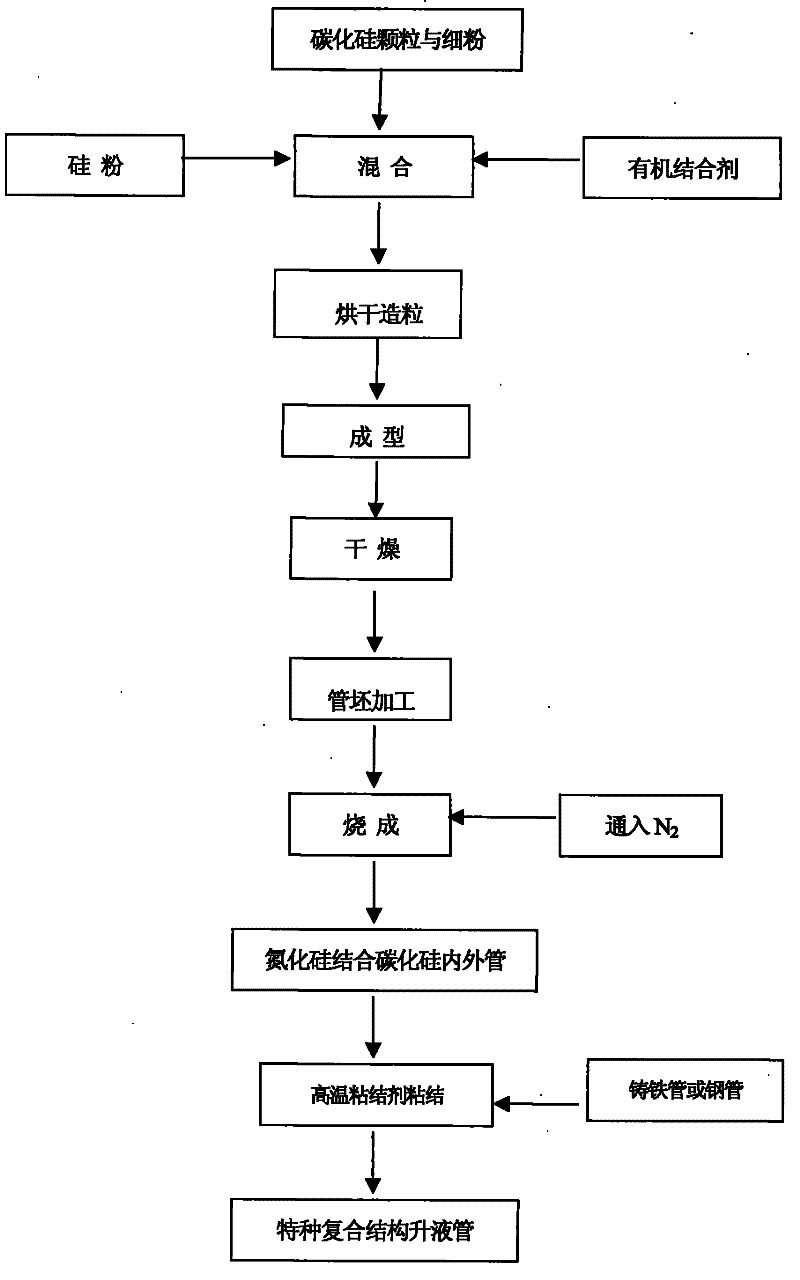

[0046] Such as figure 1 The technological process shown, the production process is as follows:

[0047] (1) The preparation of silicon nitride-bonded silicon carbide inner and outer tubes includes the following continuous steps:

[0048] A. According to silicon carbide: silicon = 70:30, weighing 2 ~ 1mm accounted for 40%, 1 ~ 0.088mm accounted for 20%, less than 0.088mm accounted for 10% of various silicon carbide raw materials and 30% silicon powder in the mixer Mix for 5-6 minutes, then add liquid resin accounting for 3% of the total amount of the above raw materials as a binder, and mix for another 15-20 minutes. The batch material is dried at 60°C and then sieved, and the material between 0.1 and 2.5 mm is retained to form the granulated material.

[0049] B. The above-mentioned granulated batch is subjected to cold isostatic pressing under a pressure of 140 MPa.

[0050] C. Dry the pressed tube blank at 200°C for 24 hours.

[0051] D. The dried tube blank is processed...

Embodiment 2

[0056] Such as figure 1 The technological process shown, the production process is as follows:

[0057] (1) The preparation of silicon nitride-bonded silicon carbide inner and outer tubes includes the following continuous steps:

[0058] A. According to silicon carbide: silicon = 75:25, weighing 2 ~ 1mm accounted for 45%, 1 ~ 0.088mm accounted for 15%, less than 0.088mm accounted for 15% of various silicon carbide raw materials and 25% silicon powder in the mixer Mix for 5-6 minutes, then add liquid resin accounting for 4% of the total amount of the above raw materials as a binder, and mix for another 15-20 minutes. The batch material is dried at 50°C and then sieved, and the material between 0.1 and 2.5mm is retained to form the granulated material.

[0059] B. The above granulated batch is subjected to cold isostatic pressing under a pressure of 150 MPa.

[0060] C. Dry the pressed tube blank at 150°C for 24 hours.

[0061] D. The dried tube blank is processed into the r...

Embodiment 3

[0066] Such as figure 1 The technological process shown, the production process is as follows:

[0067] (1) The preparation of silicon nitride-bonded silicon carbide inner and outer tubes includes the following continuous steps:

[0068] A. According to silicon carbide: silicon = 80:20, weighing 2 ~ 1mm accounted for 40%, 1 ~ 0.088mm accounted for 15%, less than 0.088mm accounted for 25% of various silicon carbide raw materials and 20% silicon powder in the mixer Mix for 5-6 minutes, then add liquid resin accounting for 3% of the total amount of the above raw materials as a binder, and mix for another 15-20 minutes. The batch material is dried at 60°C and then sieved, and the material between 0.1 and 2.5 mm is retained to form the granulated material.

[0069] B. The above-mentioned granulated batch is subjected to cold isostatic pressing under a pressure of 140 MPa.

[0070] C. Dry the pressed tube blank at 180°C for 24 hours.

[0071] D. The dried tube blank is processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com