Method for manufacturing multipurpose metal working lubricant

A technology of metal processing and manufacturing methods, applied in the direction of lubricating compositions, petroleum industry, base materials, etc., can solve the problems of poor cleaning conditions, etc., and achieve the effect of simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

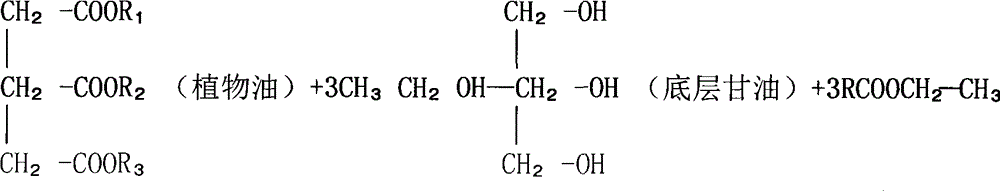

Method used

Image

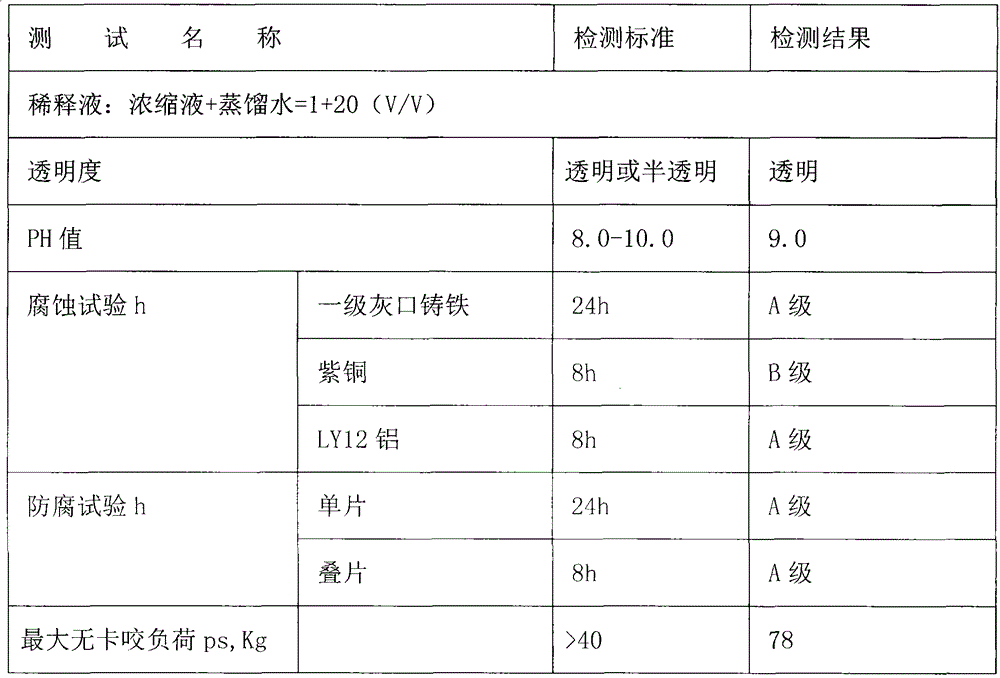

Examples

specific Embodiment

[0015] Raw materials are prepared according to the following proportions by mass,

[0016] Vegetable oil is: 100 parts;

[0017] Span-80: 1 part;

[0018] Urea: 0.5 parts;

[0019] Antioxidant BHT: 0.1 parts;

[0020] Industrial alcohol: 8 parts;

[0021] Emulsifier 6501 (fatty alcohol alkanolamide): 3 parts;

[0022] Emulsifier TX-10 (nonylphenol polyoxyethylene ether): 5 parts;

[0023] Benzotricarbazole: 0.3 parts,

[0024] Water: 0.5 points.

[0025] Among the above raw materials, the molecular formula of Span-80 is: C60H108O8, and its chemical name: sorbitan trioleate. As a non-ionic surfactant, it can be used as an emulsifier, solubilizer, suspending agent, lubricant, etc.

[0026] The antioxidant BHT was invented by a German company and is widely used in industrial applications to prevent the acid value or viscosity of lubricating oil and fuel oil from increasing.

[0027] The molecular formula of benzotricarbazole is: C6H5N3, which is mainly used as water trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com