Equipment for preparing multifunctional amorphous composite material

An amorphous composite material, multi-functional technology, applied in the field of melt infiltration and solidification, to achieve the effect of high fracture toughness, high hardness and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Amorphous composite material preparation:

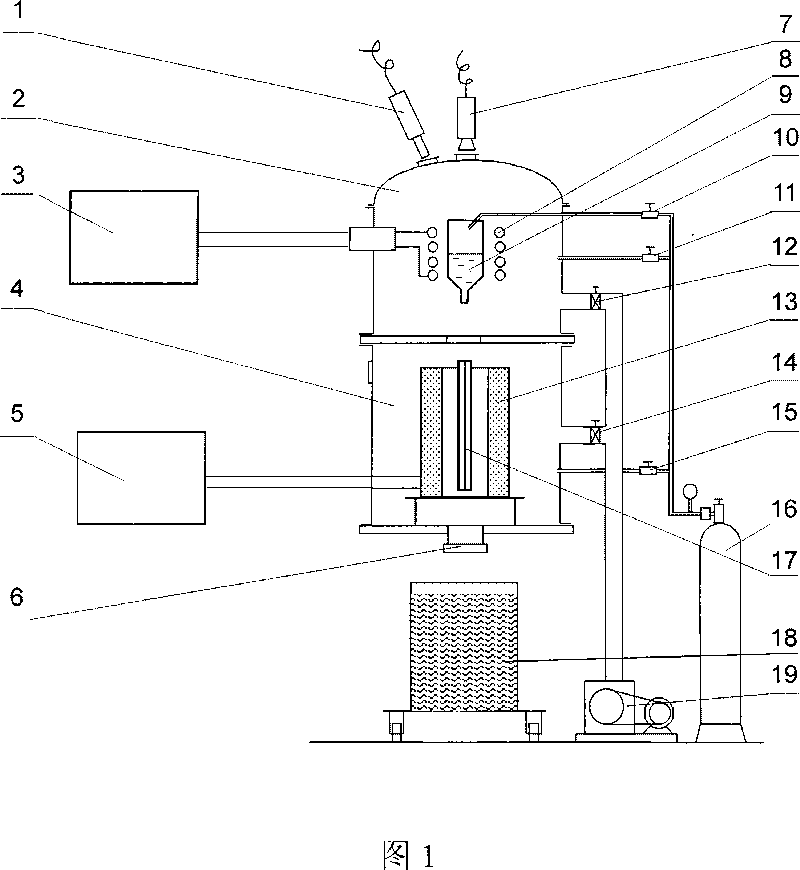

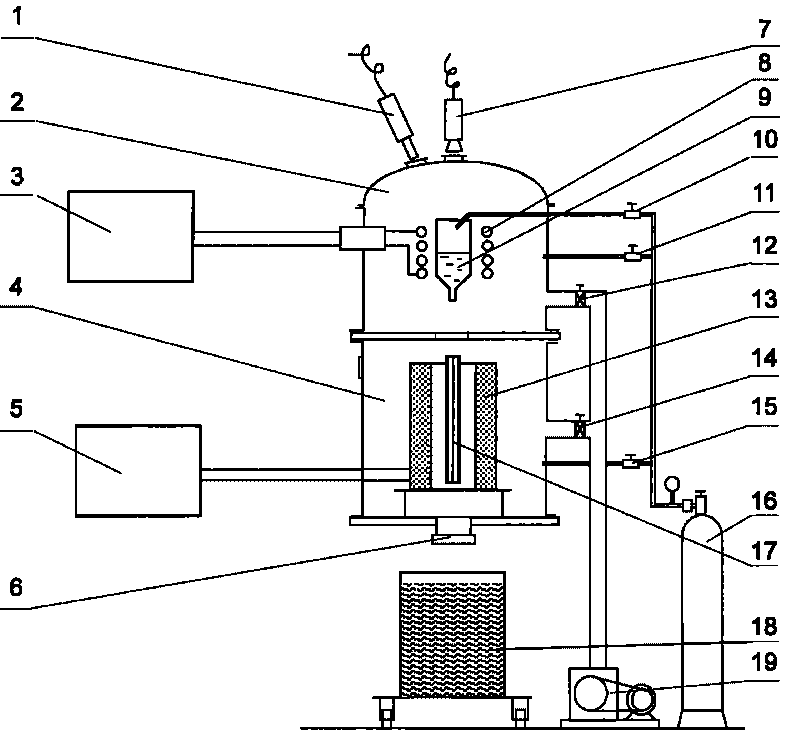

[0029] as attached figure 1 , connect the upper vacuum chamber 2 and the lower vacuum chamber 4, put the master alloy as the matrix into the quartz crucible 9, put the reinforcing phase preform into the mold 17 and place it in the heating furnace 13, start the vacuum unit 19, open the The high vacuum valve I 12 and the high vacuum valve II 14 are evacuated to a high vacuum state; the heating furnace 13 is started to preheat the mold 17 and the reinforcing phase preform; after the heating furnace 13 is heated to 50°C above the melting point of the master alloy and kept for 10 minutes, Start the intermediate frequency induction heating power source 3 to start melting the master alloy, measure and control the temperature of the alloy melt through the infrared thermometer 1, and observe the alloy melting situation through the camera 7. After the alloy is melted, open the inflatable valve I 10 and fill the inert gas into the quar...

Embodiment 2

[0031] Alloy Melting:

[0032]The upper vacuum chamber 2 and the lower vacuum chamber 4 are separated by a blind plate, and the crucible 9 is a water-cooled copper crucible. The pre-configured raw materials are inserted into the crucible 9, the vacuum unit 19 is started, the high vacuum valve 112 is opened, the upper vacuum chamber 2 is pumped to a high vacuum, the intermediate frequency induction heating power supply 3 is started to start smelting, and the infrared thermometer 1 is measured. And the temperature of the alloy melt is controlled, and the situation of the alloy melt can be observed through the camera 7 . After all the raw materials are completely melted, the temperature is kept for 5-10 minutes to make the alloy composition uniform, and then the intermediate frequency induction heating power supply 3 is turned off, and the alloy melting is completed. If the alloy contains volatile components such as Mg, Zn, etc., after the upper vacuum chamber 2 is pumped to a h...

Embodiment 3

[0034] To prepare pure amorphous samples:

[0035] The upper vacuum chamber 2 and the lower vacuum chamber 4 are separated by a blind plate, the crucible 9 is a water-cooled copper crucible, and a copper mold is placed on the blind plate below the crucible. The master alloy Zr 55 Al 10 Ni 5 Cu 30 Put in the crucible 9, start the vacuum unit 19, open the high vacuum valve 112, pump the upper vacuum chamber 2 to high vacuum, start the intermediate frequency induction heating power source 3 to start smelting, measure and control the alloy melt by the infrared thermometer 1. temperature, the melting of the alloy can be observed through the camera 7. After holding the temperature for 2 minutes at a temperature of 150°C above the melting point of the alloy, the inversion device was started, and the alloy was poured into a copper mold to form an amorphous rod. Tumble casting under vacuum avoids the formation of pores in amorphous samples and improves their performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com