Aluminum plastic laminated tube and method for producing the same

A technology of aluminum-plastic composite pipe and manufacturing method, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of easy mutual sliding, poor aging resistance, slow deformation, etc., and achieve outstanding long-term pressure resistance. The effect of superior toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

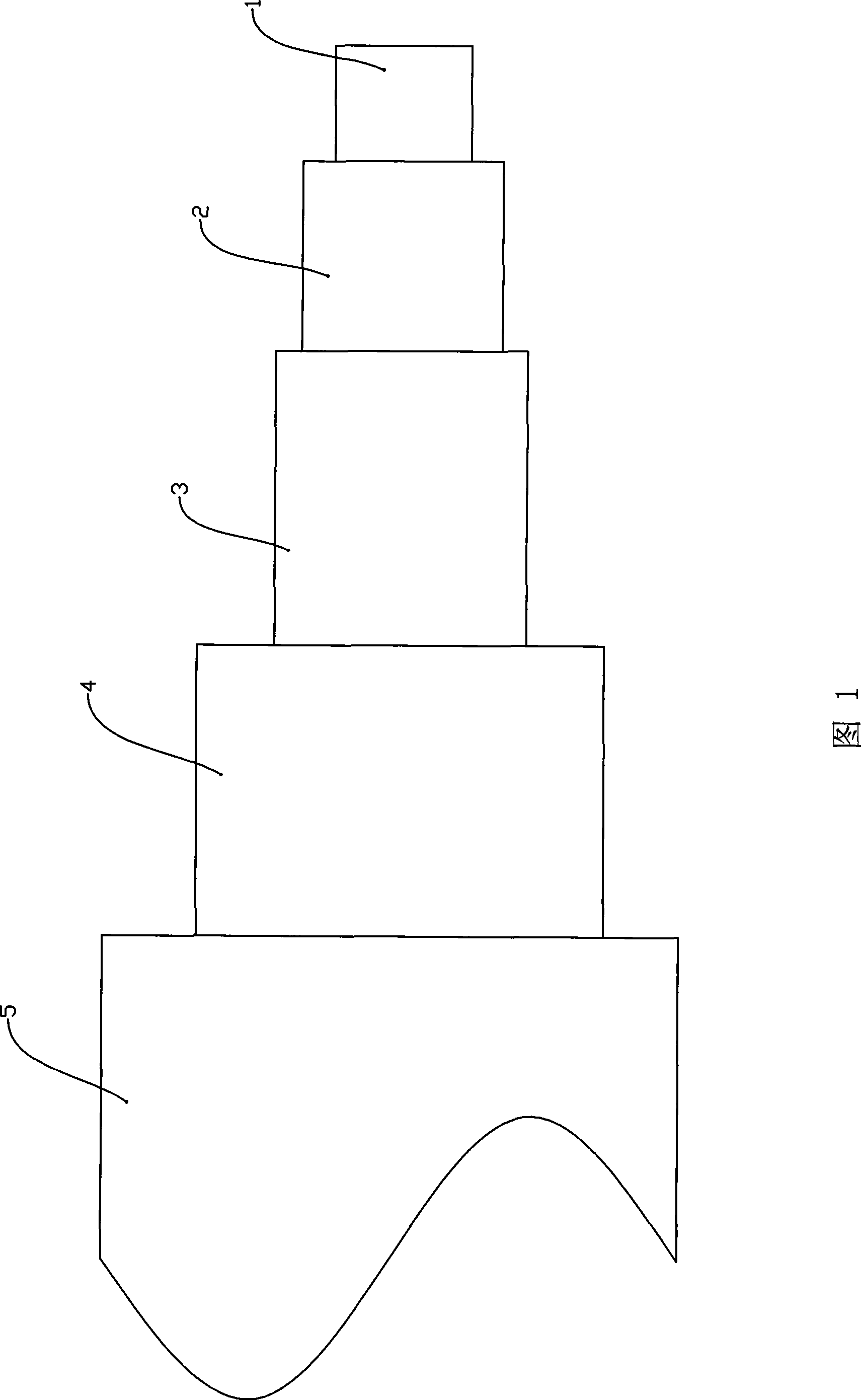

[0026] Referring to Fig. 1, it is a cross-sectional view of the aluminum-plastic composite pipe of the present invention. A new type of aluminum-plastic composite pipe, which comprises an inner layer of medium-density polyethylene 1, a hot-melt adhesive 2, an aluminum pipe 3, a hot-melt adhesive 4 and an outer layer of medium-density polyethylene 5 from the inside to the outside. Medium-density polyethylene is a new type of heating material with stable mechanical properties. It is made of ethylene and octene monomers through metallocene-catalyzed copolymerization. The weight ratio of each layer of the above-mentioned aluminum-plastic composite pipe varies according to the type of aluminum-plastic composite pipe. Take the butt-type aluminum-plastic composite pipe 1216 as an example: polyethylene, hot melt adhesive, aluminum tube, hot melt adhesive, polyethylene The weight ratio is: 45:5:60:2.5:25.

[0027] The aluminum-plastic composite pipe of the present invention changes th...

Embodiment 2

[0029] In addition to using medium-density polyethylene for both the inner and outer layers of polyethylene as described in the above-mentioned implementation one, the inner layer of polyethylene can still use traditional high-density polyethylene, while the outer layer of polyethylene can use medium-density polyethylene, because The physical properties of the outer layer of polyethylene have a greater impact on the performance of the entire aluminum-plastic composite pipe.

[0030] The manufacturing method of the aluminum-plastic composite pipe described in the first embodiment is described below.

[0031] The production process is basically the same as the traditional aluminum-plastic composite pipe, including the following steps;

[0032] (1) Extrusion of polyethylene inner tube;

[0033] (2) Vacuum sizing;

[0034] (3) Spray cooling;

[0035] (4) hot air drying;

[0036] (5) Inner rubber extrusion;

[0037] (6) Aluminum strip welding and forming;

[0038] (7) full ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com