Method for preparing crosslinking butadiene-acrylonitrile copolymer rubber

A technology of butadiene and acrylonitrile, which is applied in the field of preparation of cross-linked butadiene-acrylonitrile copolymer rubber, can solve the problems of difficulty in controlling the degree of cross-linking and limitation of application fields, and achieves low product shrinkage and processing performance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

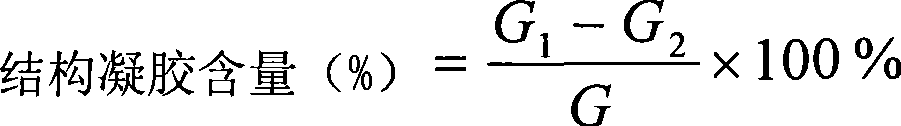

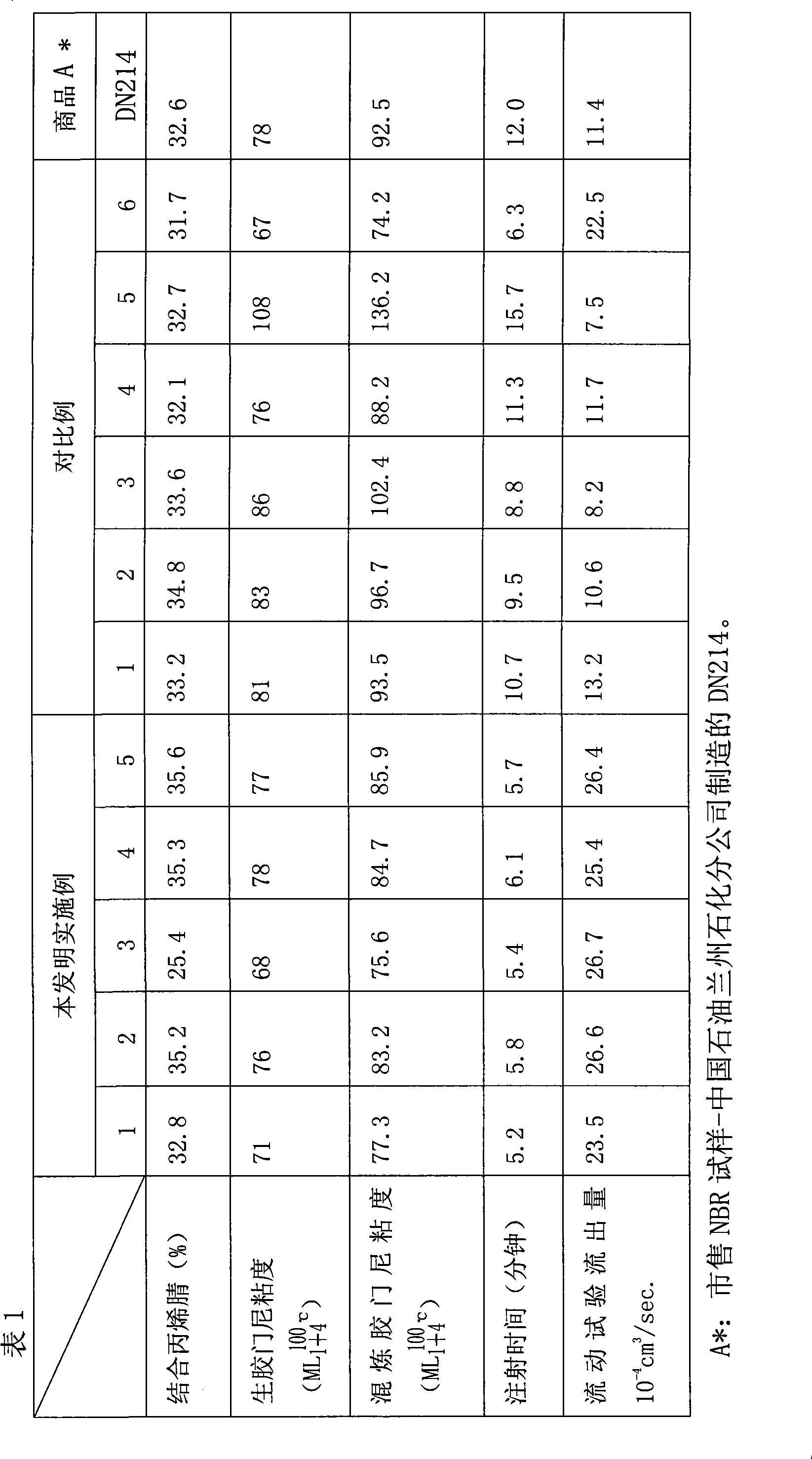

Embodiment 1

[0037] In a reactor with a mixer and a capacity of 30L, add 65 parts of butadiene, 35 parts of acrylonitrile, 0.1 part of 1-tris(3-methacrylate) propane, 0.5 parts of dodecyl The complex soap of the sodium benzenesulfonate and the potassium oleate of 2.5 parts, the tert-dodecyl mercaptan of 0.5 part, 0.3 part of potassium persulfate, 0.02 part of triethanolamine, 100 parts of water, carry out emulsion polymerization at 25 ℃, When the conversion rate reaches 40-45%, add 0.1 part of 1-tris(3-methacrylate) propane, when the conversion rate reaches 70-75%, heat up to 40°C to maintain the polymerization reaction, the conversion rate is 90- 97% add a terminator to terminate the polymerization reaction. Obtained polymer bound acrylonitrile 32.8%, Mooney viscosity 71, structure gel 53.2%, shrinkage: 27.8%

Embodiment 2

[0039] In a reactor with a mixer and a capacity of 30L, add 62 parts of butadiene, 38 parts of acrylonitrile, 0.1 part of dimethyl (acrylate) glycol ester, and 1.0 part of dodecylbenzenesulfonate The complex soap of sodium stearate and 2.0 parts of potassium stearate, 0.5 parts of tert-dodecyl mercaptan, 0.3 parts of potassium persulfate, 0.02 parts of triethanolamine, 100 parts of water, carry out emulsion polymerization at 15 ° C, when conversion When the conversion rate reaches 35-40%, add 0.1 part of dimethyl (acrylate) glycol ester. When the conversion rate reaches 70-75%, raise the temperature to 50°C to maintain the polymerization reaction, and the conversion rate is 90-97%. agent to terminate the polymerization reaction. Obtained polymer bound acrylonitrile 35.2%, Mooney viscosity 76, structure gel 63.7%, shrinkage: 23.6%

Embodiment 3

[0041] In a reactor with a mixer and a capacity of 30L, add 74 parts of butadiene, 26 parts of acrylonitrile, 0.2 parts of dimethyl (acrylate) glycol ester, and 1.5 parts of sodium lauryl sulfate And 2.0 parts of potassium oleate complex soap, 0.5 parts of tert-dodecyl mercaptan, 0.3 parts of potassium persulfate, 0.02 parts of dimethylamine, 100 parts of water, carry out emulsion polymerization at 15 ° C, when the conversion When it reaches 30-35%, add 0.1 part of dimethyl (acrylate) glycol ester, when the conversion rate reaches 50-55%, add 0.1 part of dimethyl (acrylate) glycol ester, when When the conversion rate reaches 70-75%, the temperature is raised to 45°C to maintain the polymerization reaction, and when the conversion rate is 90-97%, a terminator is added to terminate the polymerization reaction. Obtained polymer bound acrylonitrile 25.4%, Mooney viscosity 68, structure gel 88.5%, shrinkage: 21.7%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com