Bi2S3-BaTiO3/PVDF composite material and preparation method thereof

A bi2s3-batio3, 1.bi2s3-batio3 technology is used in the preparation of capacitors, ultra-high dielectric three-phase composite materials and their preparation fields, which can solve the problems of low dielectric constant and achieve low inorganic content and mechanical processing performance. Good, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

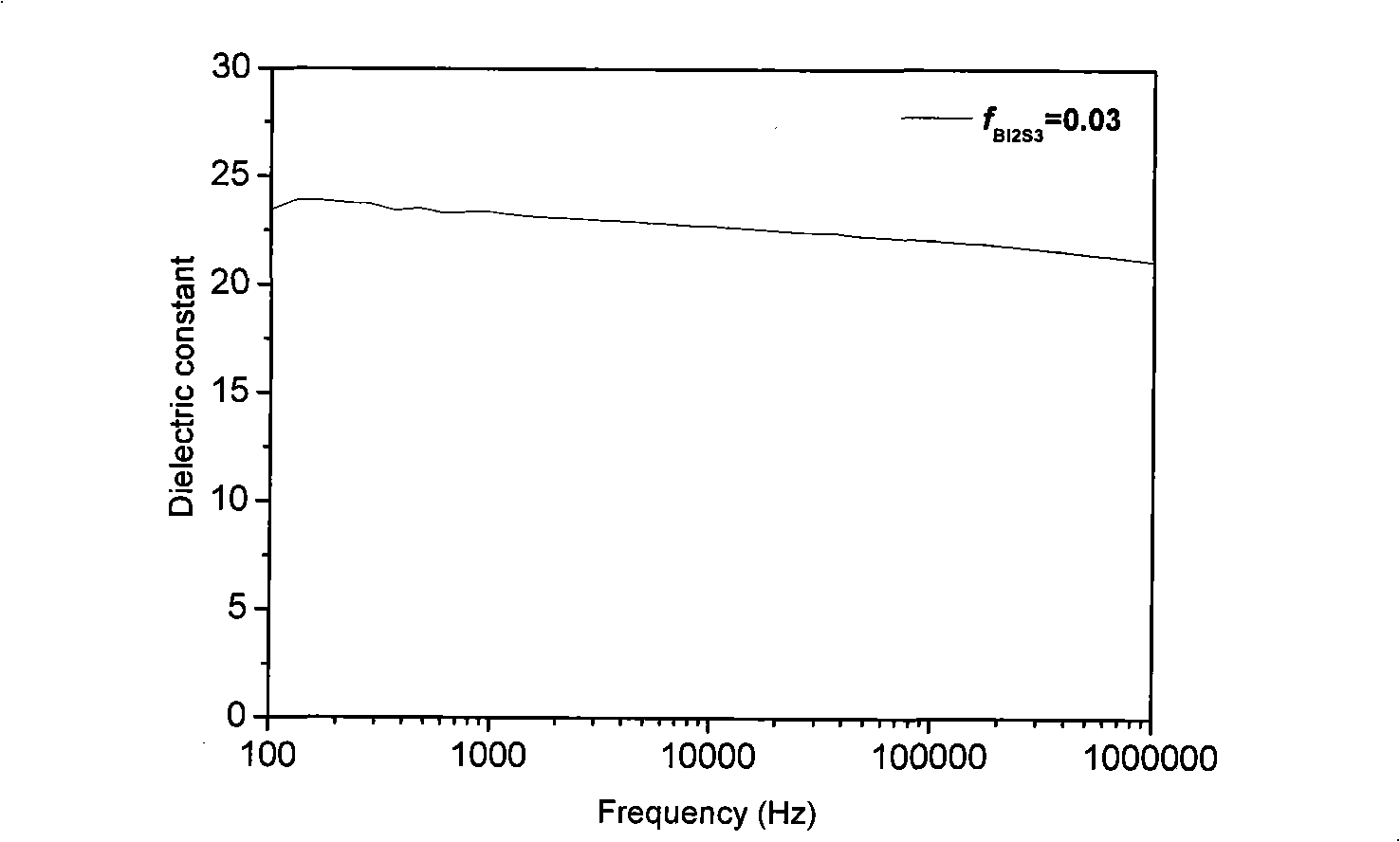

[0036] Embodiment 1 prepares volume percentage f Bi2S3 = 0.03 Composite. Specific steps are as follows:

[0037] (1) According to volume percentage f Bi2S3 =0.03,f BaTiO3 =0.20,f PVDF =0.77, weigh the raw materials. Change the volume fraction into mass number, each raw material is: 0.0790g, 0.3900g, 0.4620g, and weigh the experimental raw materials.

[0038] (2) Add the weighed PVDF into 40ml of N,N-dimethylformamide (DMF), fully dissolve to form a transparent solution.

[0039] (3) The weighed BaTiO 3 and Bi 2 S 3 The nanorods were added to the above transparent solution, and ultrasonically oscillated for 20 minutes to make the Bi 2 S 3, BaTiO 3 Disperses evenly in solution to form a stable suspension.

[0040] (4) Pour the above suspension into a watch glass and then place it in an oven at 100° C. to dry to obtain a dielectric film.

[0041] (5) Hot pressing the above dielectric film and testing the dielectric properties. Hot pressing conditions: 210°C, 10MPa, ...

Embodiment 2

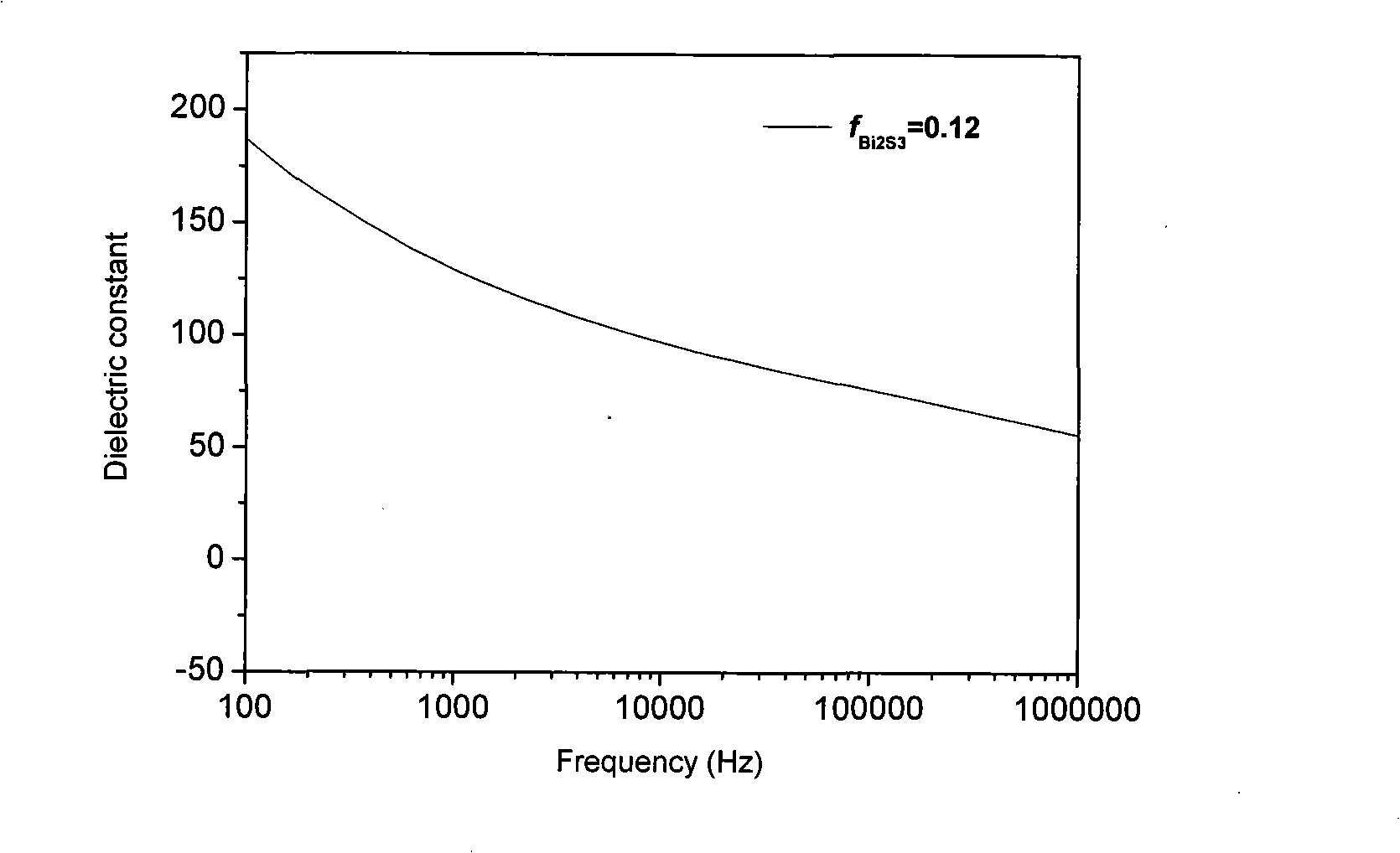

[0043] Embodiment 2: preparation volume percent f Bi2S3 = 0.12 Composite. Specific steps are as follows:

[0044] (1) According to volume percentage f Bi2S3 =0.12,f BaTiO3 =0.20,f PVDF =0.69 Weigh the raw material. Change the volume fraction into mass number, each raw material is: 0.3160g, 0.3900g, 0.4140g, and weigh the experimental raw materials.

[0045] (2) Add the weighed PVDF into 30ml of N,N-dimethylformamide (DMF), fully dissolve to form a transparent solution.

[0046] (3) The weighed BaTiO 3 and Bi 2 S 3 Add to the above transparent solution, ultrasonic vibration for 20min, make Bi 2 S 3 , BaTiO 3 Disperses evenly in solution to form a stable suspension.

[0047] (4) Pour the above suspension into a watch glass and dry in an oven at 100° C. to obtain a dielectric film.

[0048] (5) Hot pressing the above dielectric film and testing the dielectric properties. Hot pressing conditions: 210°C, 10MPa, 25min.

[0049] figure 2 It is the relationship diagra...

Embodiment 3

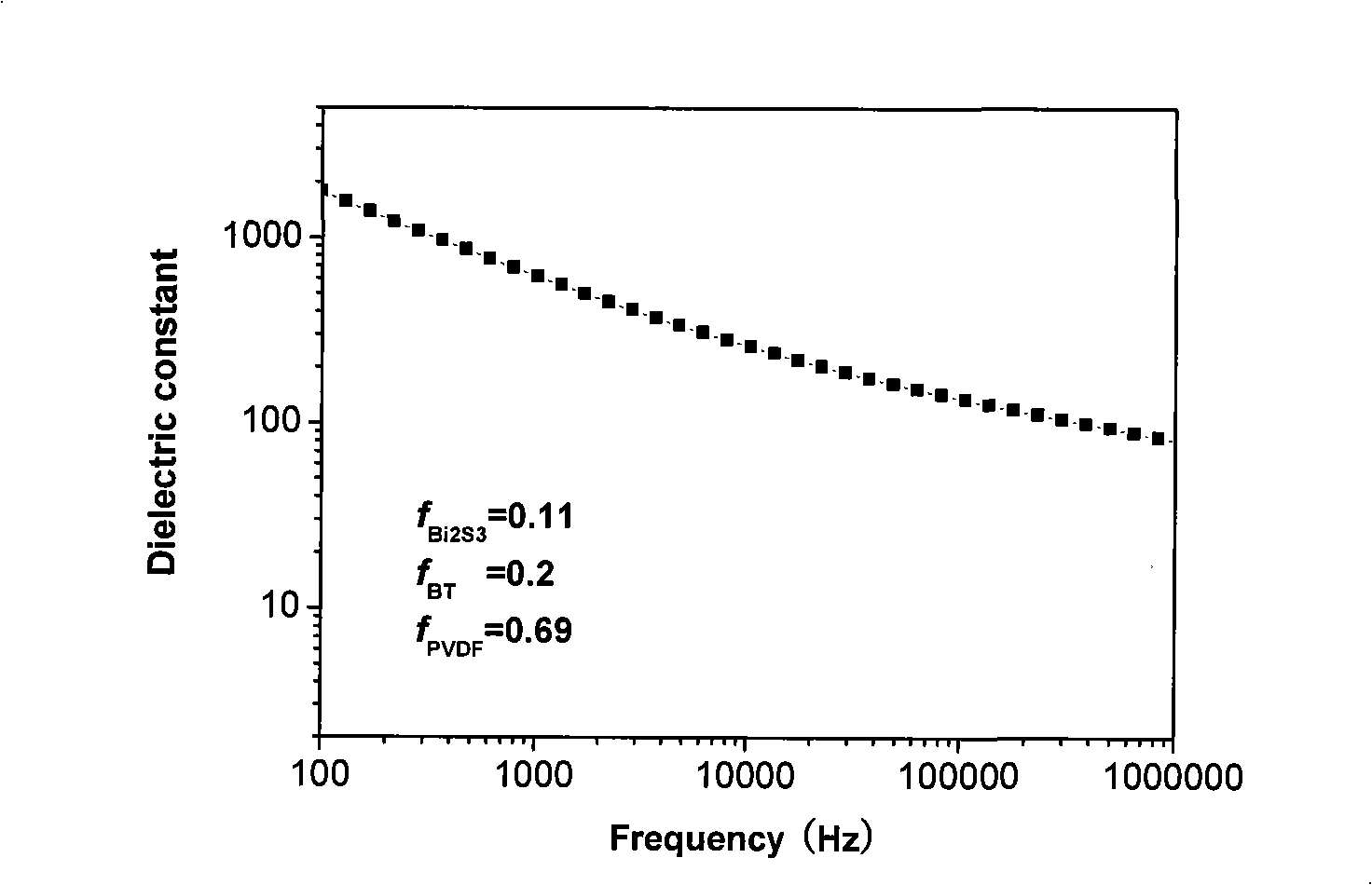

[0050] Embodiment 3: preparation volume percent f Bi2S3 = 0.11 Composite material. Specific steps are as follows:

[0051] (1) According to volume percentage f Bi2S3 =0.11, f BaTiO3 =0.20, f PVDF =0.69 Weigh the raw materials, change the volume fraction into the mass number, each raw material is respectively: 0.2900g, 0.3900g, 0.4140g, and weigh the experimental raw materials.

[0052] (2) Add the weighed PVDF into 35ml of N,N-dimethylformamide (DMF), fully dissolve to form a transparent solution.

[0053] (3) The weighed BaTiO 3 and Bi 2 S 3 Add to the above transparent solution, ultrasonic vibration for 20min, make Bi 2 S 3 , BaTiO 3 Disperses evenly in solution to form a stable suspension.

[0054] (4) Pour the above suspension into a watch glass and dry in an oven at 100° C. to obtain a dielectric film.

[0055] (5) Dielectric properties tested by hot pressing. The dielectric film was hot-pressed and tested for its dielectric properties, hot-pressing condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com