Hollow nanostructured hydroxyapatite and method for producing the same

A technology of hydroxyapatite and hollow nanometers, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as limited applications, and achieve low raw material costs, simple experimental equipment, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of elliptical hydroxyapatite hollow nanostructures with a length of 600-1000nm:

[0051] Add 0.005mol calcium nitrate, 0.003mol diammonium hydrogen phosphate, 0.005mol citric acid, 0.0013mol edetate disodium, 0.001mol sodium fluoride, 80mL deionized water to a 250mL three-necked flask, and place the three-necked flask at In a 40°C water bath, mechanically stir for 10 minutes. The resulting solution was a clear transparent liquid. The pH of the solution was then adjusted to 5.2 with 2M NaOH solution. After stirring for 5 min, the above solution was transferred into a 100 mL tetrafluoroethylene-lined hydrothermal kettle, and reacted at 150 °C for 4 h. After the product is centrifuged (4000hr / min, 10min), it is washed three times with deionized water and twice with absolute ethanol, and finally the product is placed in a vacuum drying oven and dried at 60°C for 8 hours. The resulting product was subjected to characterization tests.

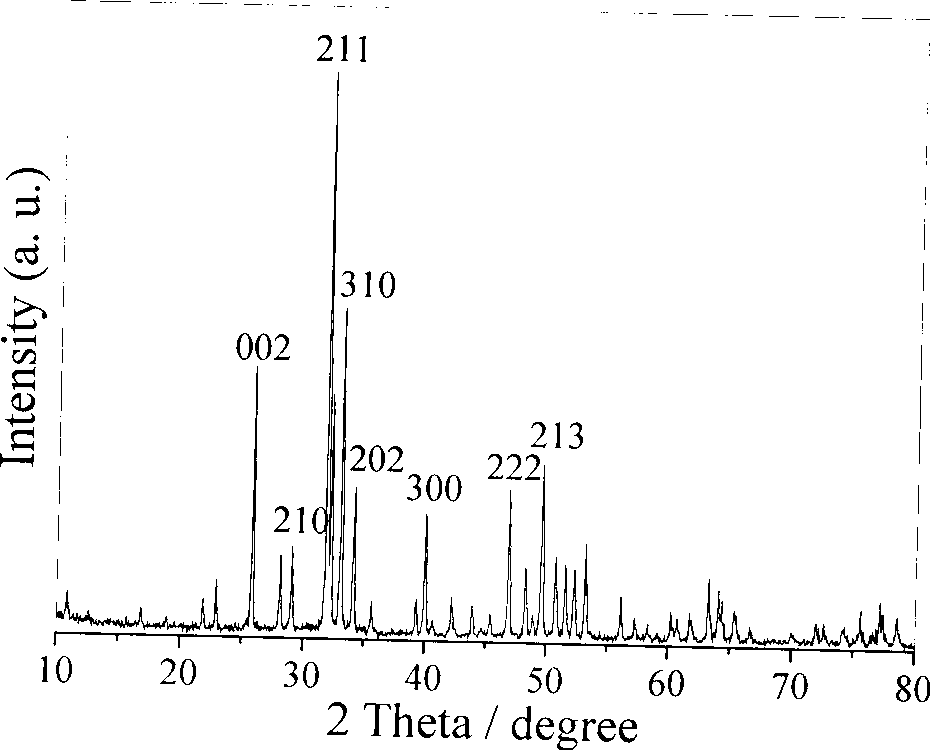

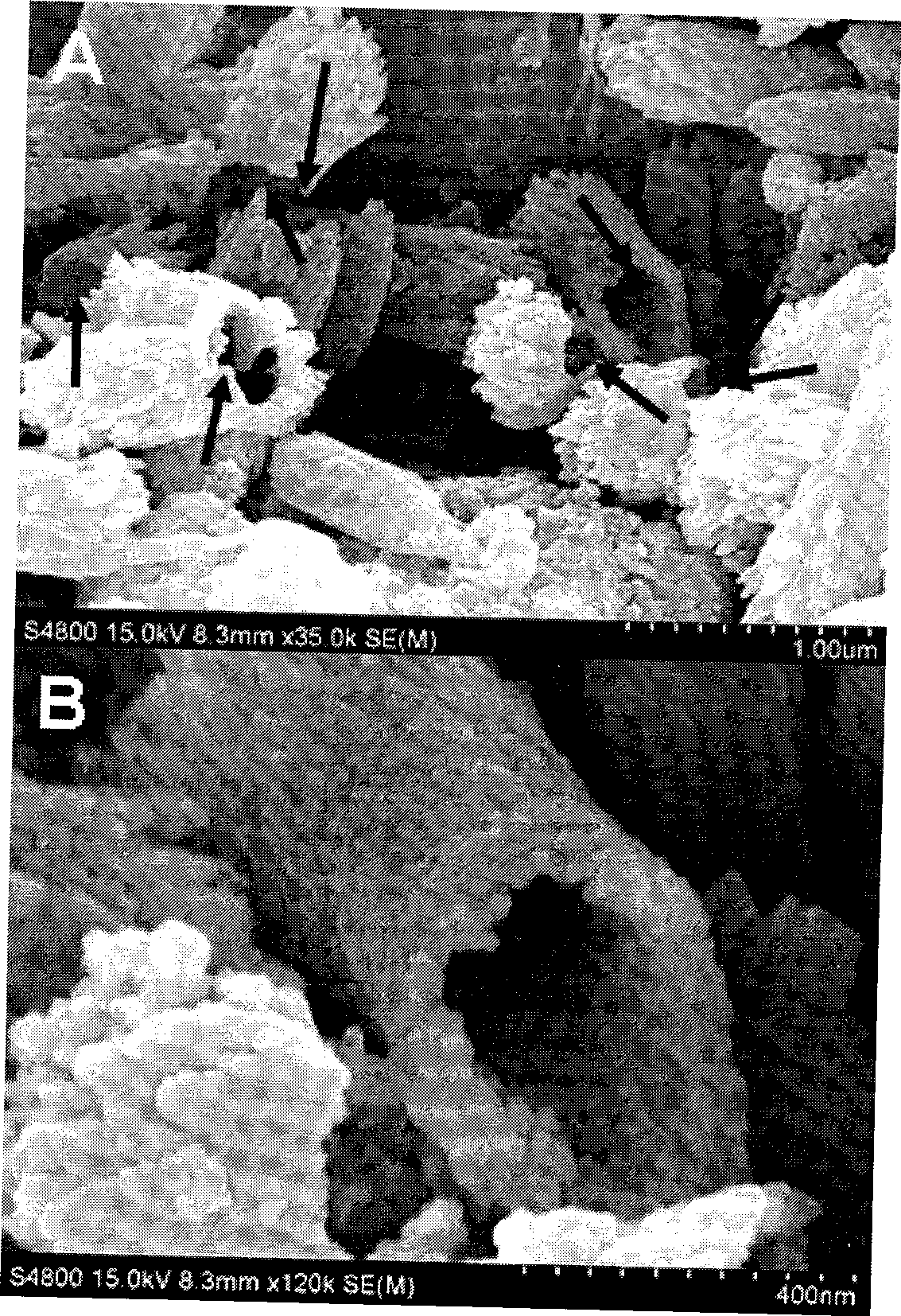

[0052] figure 1 For th...

Embodiment 2

[0055] Preparation of elliptical hydroxyapatite hollow nanostructures with a length of 600-800nm:

[0056] Add 0.005mol calcium nitrate, 0.003mol ammonium dihydrogen phosphate, 0.005mol citric acid, 0.0025mol edetate disodium, 0.001mol sodium fluoride, 80mL deionized water to a 250mL three-necked flask, and place the three-necked flask at In a 40°C water bath, mechanically stir for 10 minutes. The resulting solution was a clear transparent liquid. The pH of the solution was then adjusted to 4.5 with 2M NaOH solution. After stirring for 5 min, the above solution was transferred into a 100 mL tetrafluoroethylene-lined hydrothermal kettle, and reacted at 130 °C for 2 h. After the product is centrifuged (4000hr / min, 10min), it is washed three times with deionized water and twice with absolute ethanol, and finally the product is placed in a vacuum drying oven and dried at 60°C for 8 hours. The resulting product was subjected to characterization tests.

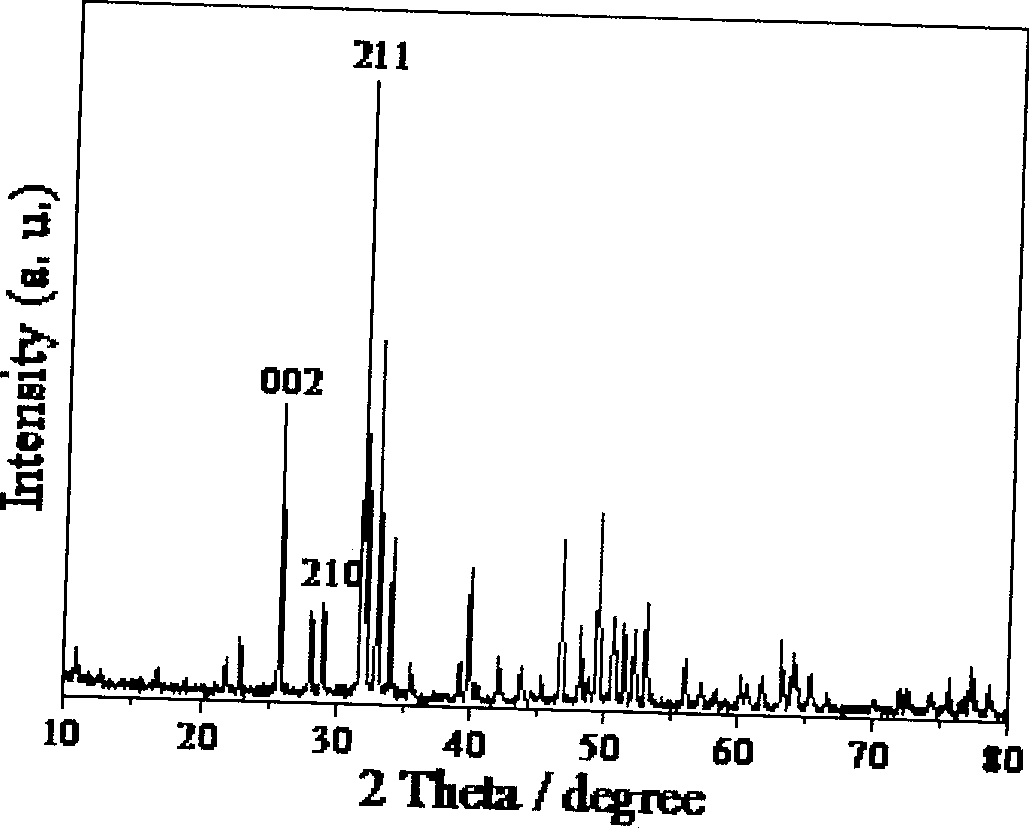

[0057] image 3 For the...

Embodiment 3

[0060] Preparation of spindle-shaped hollow nanostructures of hydroxyapatite with a length of 1000-1200nm:

[0061] Add 0.005mol calcium nitrate, 0.003mol diammonium hydrogen phosphate, 0.005mol citric acid, 0.004mol edetate disodium, 0.001mol sodium fluoride, 80mL deionized water to a 250mL three-necked flask, and place the three-necked flask at In a 40°C water bath, mechanically stir for 10 minutes. The resulting solution was a clear transparent liquid. The pH of the solution was then adjusted to 3.6 with 2M NaOH solution. After stirring for 5 min, the above solution was transferred into a 100 mL tetrafluoroethylene-lined hydrothermal kettle, and reacted at 120 °C for 4 h. After the product is centrifuged (4000hr / min, 10min), it is washed three times with deionized water and twice with absolute ethanol, and finally the product is placed in a vacuum drying oven and dried at 60°C for 8 hours. The resulting product was subjected to characterization tests.

[0062] Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com