CuO-carbon nano-tube composite micro-nano-sphere, preparation and uses thereof

A carbon nanotube composite, carbon nanotube technology, applied in chemical instruments and methods, electrode manufacturing, electrical components and other directions, can solve problems affecting application, affecting cyclability, etc., to achieve convenient operation, improve cycle performance, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1. Preparation of CuO-carbon nanotube composite micro-nanospheres

[0027] Weigh 20 mg of purified carbon nanotubes, add 5 ml of N,N-dimethylformamide, and ultrasonically disperse for 5 hours. 1.208 g of copper nitrate and 1 g of polyoxyethylene-polyoxypropylene-polyoxyethylene P123 were dissolved in 40 ml of water with constant stirring to form a blue solution. Then, the dispersed carbon nanotubes were added into the solution, and then ultrasonicated for 2 hours to ensure that the carbon nanotubes were uniformly dispersed. Add 5 ml of 25wt% ammonia water, stir for 1 hour, reflux at 110°C for 2 hours under strong stirring, centrifuge the resulting mixture solution, wash with water, and the obtained precipitate is the CuO-carbon nanotube composite micro-nano ball.

Embodiment 2

[0028] Example 2, preparation of CuO-carbon nanotube composite micro-nanospheres

[0029] Weigh 50 mg of purified carbon nanotubes, add 5 ml of N,N-dimethylformamide, and ultrasonically disperse for 5 hours. 1.95 g of copper nitrate and 1 g of polyoxyethylene-polyoxypropylene-polyoxyethylene P123 were dissolved in 40 ml of water with constant stirring to form a blue solution. Then, the dispersed carbon nanotubes were added into the solution, and then ultrasonicated for 2 hours to ensure that the carbon nanotubes were uniformly dispersed. Add 15 ml of 25wt% ammonia water, stir for 1 hour, reflux at 130°C for 2 hours under strong stirring, centrifuge the resulting mixture solution, wash with water, and the precipitate obtained is the CuO-carbon nanotube composite micro-nano ball.

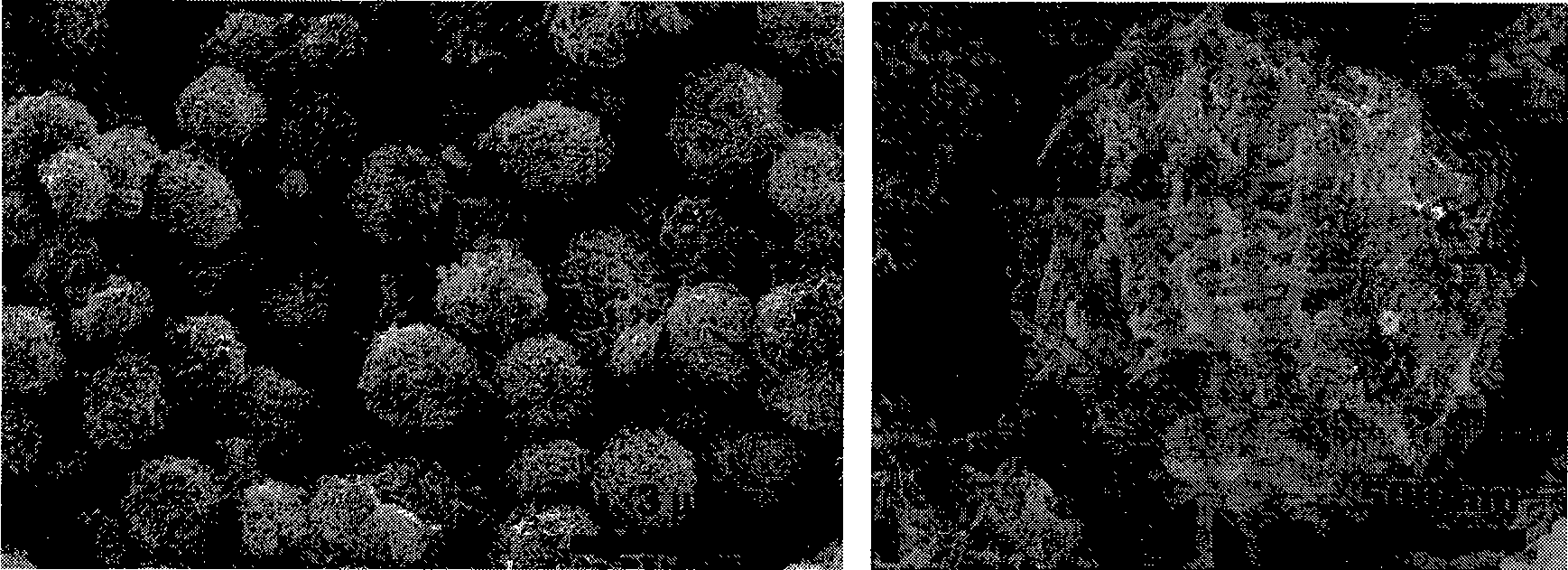

[0030] figure 1 It is an electron micrograph of the obtained CuO-carbon nanotube composite micro-nanosphere. It can be seen from the figure that CuO and carbon nanotube form a uniform composite mic...

Embodiment 3

[0031] Example 3, Electrical performance test of CuO-carbon nanotube composite micro-nanosphere

[0032] Taking CuO micro-nanospheres as a comparison, the preparation process of CuO micro-nanospheres is as follows:

[0033] 1.208 g of copper nitrate and 1 g of polyoxyethylene-polyoxypropylene-polyoxyethylene P123 were dissolved in 40 ml of water with constant stirring to form a blue solution. Subsequently, 10 milliliters of 25 wt % ammonia water was added, and the solution turned dark blue. Then, the solution was refluxed at 110° C. for 2 hours under strong stirring, and the solution turned black. The obtained mixture solution was centrifuged, washed with water, and the obtained precipitate was the CuO micro-nanosphere of the present invention.

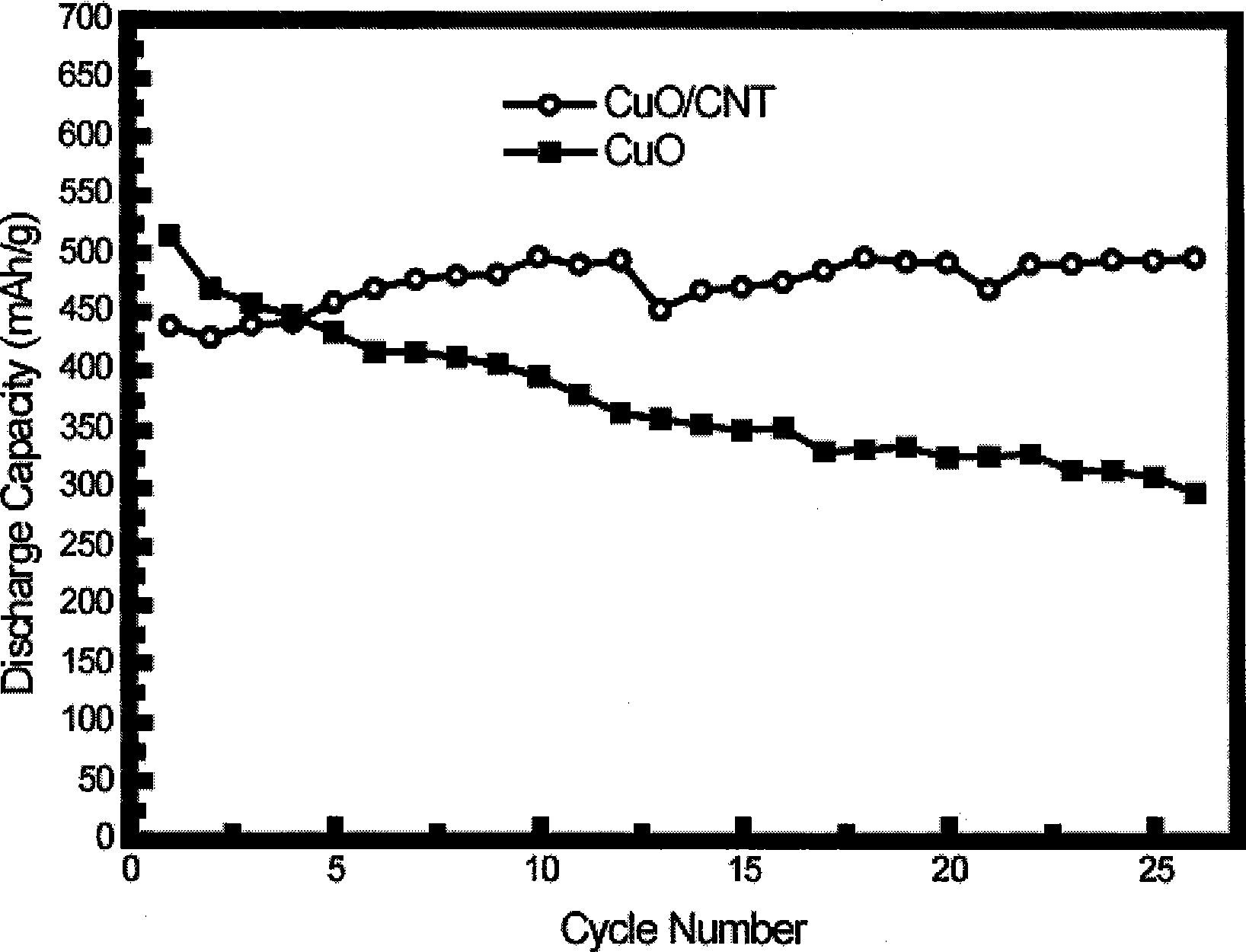

[0034] Electrochemical characterization of CuO micro-nanospheres and CuO-carbon nanotube composite micro-nanospheres: the electrochemical characterization was performed using a coin cell Li|1M LiPF6 (EC:DMC=1:1)|CuO / CuO-carbon nanotu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com