Enclosed dissociation desulfurization reactor and system

A reactor and closed technology, which is applied in the field of dissociation reactor and its system, can solve the problems of small market utilization space, resource waste, and low production efficiency, and achieve desulfurization of lead paste without waste discharge, uniform heating, and avoid sticking knot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

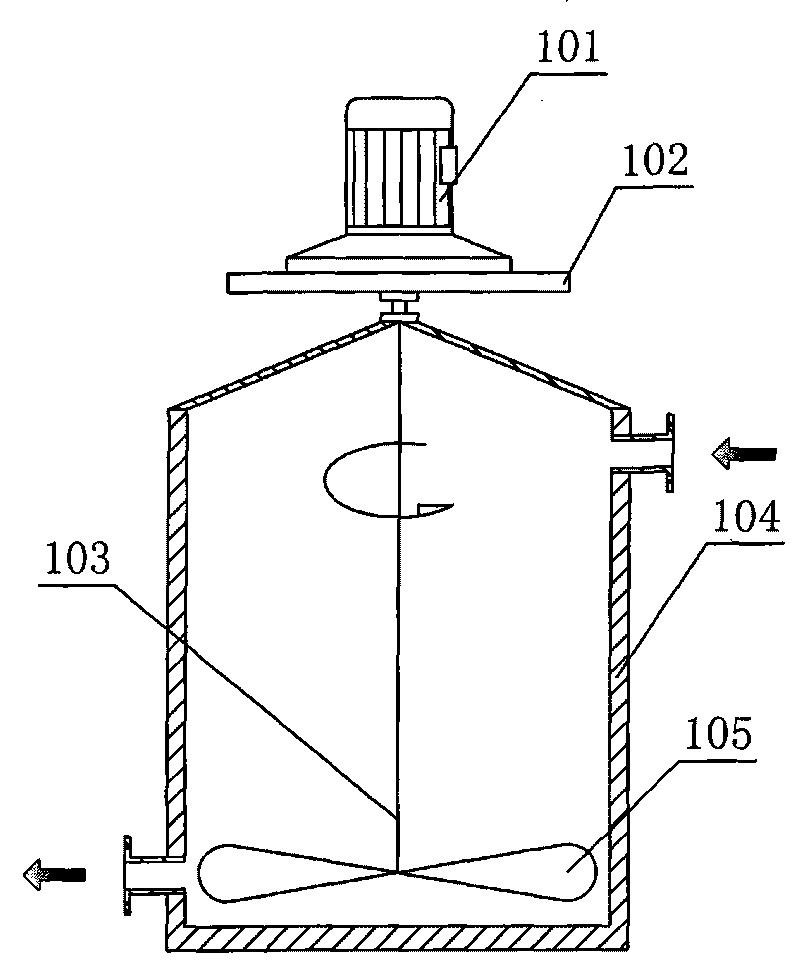

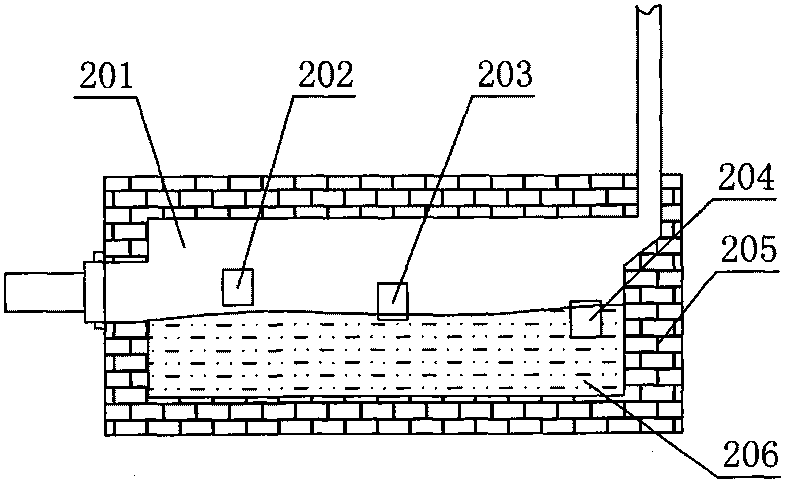

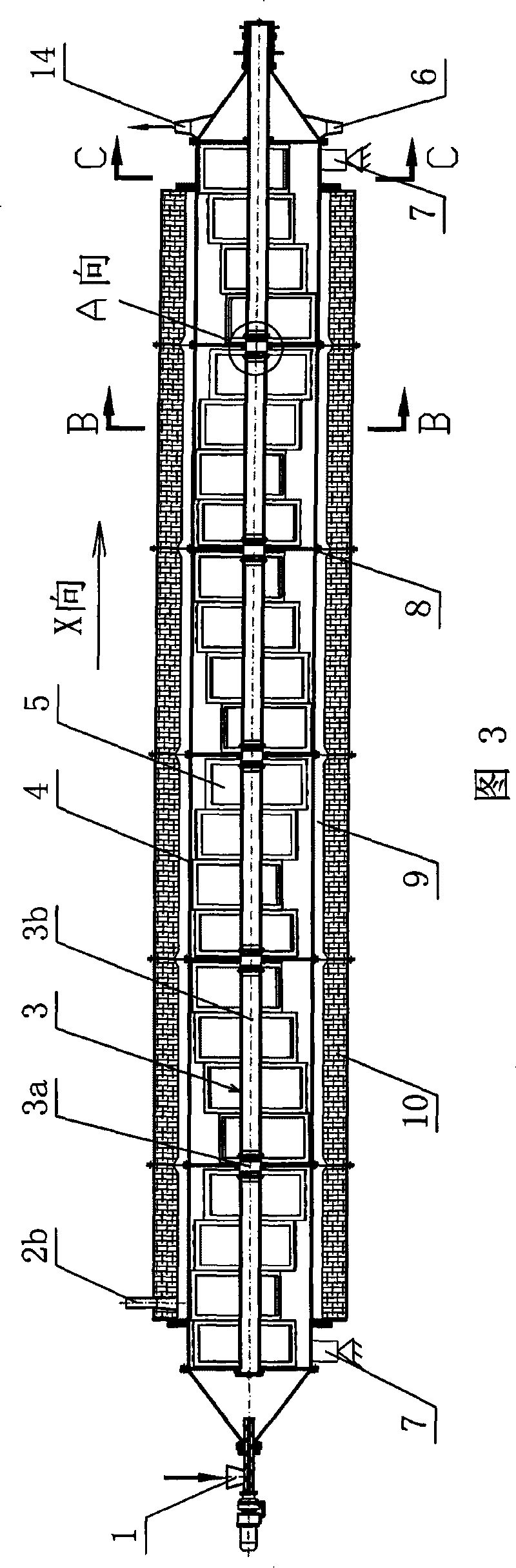

[0054] Such as Figure 3 to Figure 9 The shown closed dissociation reactor includes a desulfurization reaction tank body, a stirring mechanism, and feed inlets 1 and discharge ports respectively located at both axial ends of the tank body, wherein the stirring mechanism includes a stirrer and a stirring transmission Mechanism, the discharge port includes the main material outlet 6 and the auxiliary material outlet 14, the dissociation reactor also includes a heating device, the heating device includes a heater 9 and a temperature control system, the desulfurization reaction tank is a rotatable horizontal drum device, It is mainly composed of a horizontal drum 4, a drum support mechanism and a drum transmission mechanism, wherein the drum 4 is installed on the drum support mechanism with its rotation axis as the horizontal direction, and the agitator is along the direction of the rotation axis of the drum 4. Installed in the drum, the drum 4 and the agitator are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com