Platinum-tantalum-platinum three-layer composite screen and method for producing the same

A layer-composite and composite-layer technology is applied in the field of electrochemical anode materials and their preparation, which can solve the problems of weak bonding force between the coating and the base material, uneven coating, and porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Taking the platinum layer thickness of the finished net as 3 μm as an example, the size of the finished net requires the thickness of the platinum layer to be 3 μm, the thickness of the tantalum layer to be 0.2 mm, and the width of the net to be 30 mm.

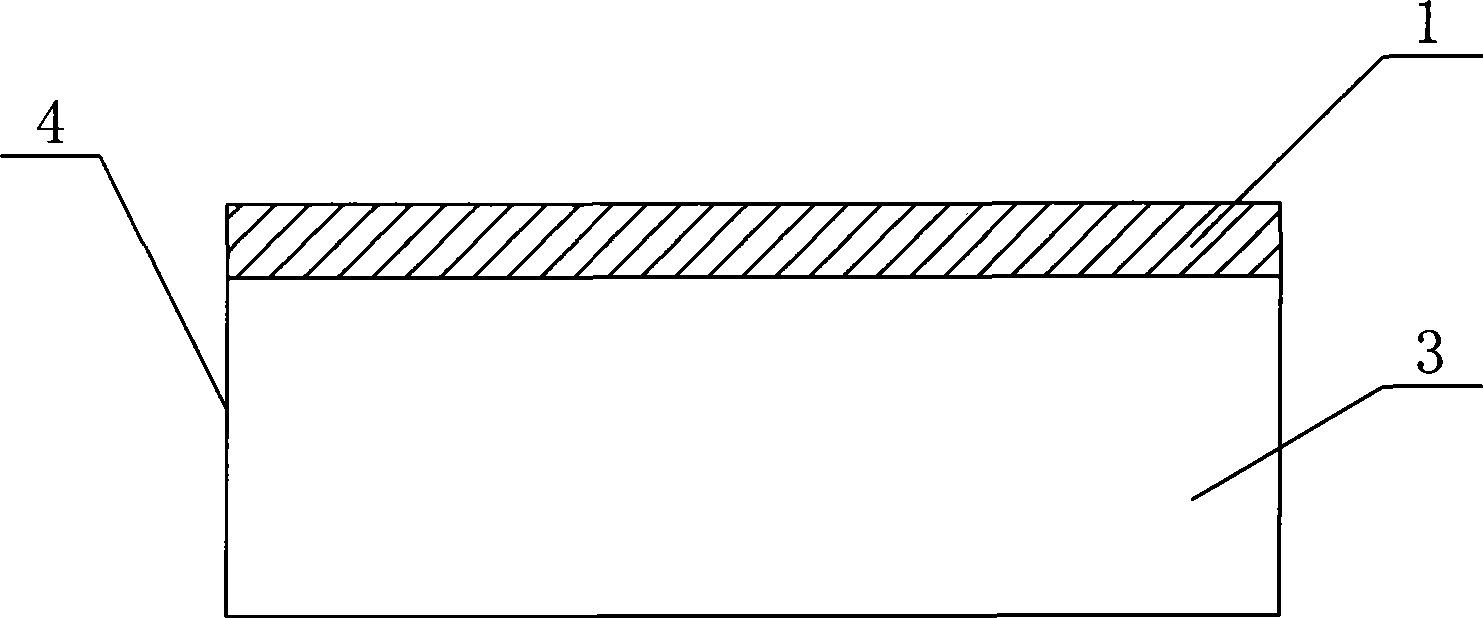

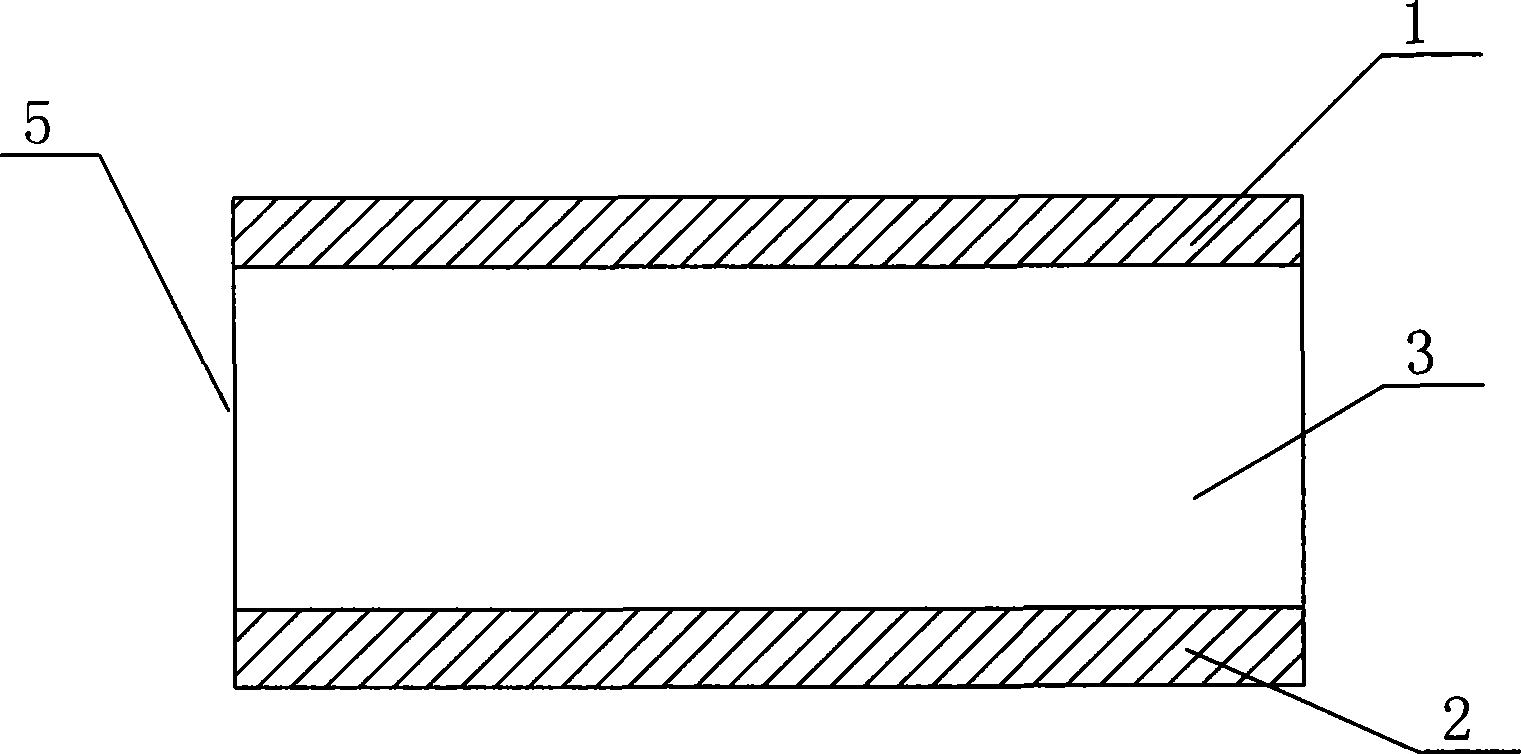

[0017] Such as figure 1 and figure 2 As shown, the processing process is:

[0018] (1) Prepare the platinum plates 1 and 2, roll the platinum plates 1 and 2 into sheets with a thickness of 0.3 mm, and cut them into two sheets of 0.3×150×200 mm.

[0019] (2) A tantalum plate 3 with a size of 20×150×200mm.

[0020] (3) Explosive compounding, using the method of parallel end detonation to first compound a platinum plate 1 and a tantalum plate 3, after the surface is polished and smoothed, another platinum plate 2 and the primary compound plate 4 are compounded twice to form a secondary compound plate 5.

[0021] (4) The secondary clad plate 5 is rolled with a D550 type rolling mill, the processing rate of each pass is...

Embodiment 2

[0025] Taking the finished net platinum layer thickness of 10 μm as an example, the finished net size requires a platinum layer thickness of 10 μm, a tantalum layer thickness of 0.3 mm, and a net width of 50 mm.

[0026] Such as figure 1 and figure 2 As shown, the processing process is:

[0027] (1) Prepare the platinum plates 1 and 2, roll the platinum plates 1 and 2 into sheets with a thickness of 1.0 mm, and cut them into two sheets of 0.3×150×200 mm.

[0028] (2) A tantalum plate 3 with a size of 30×200×400mm.

[0029] (3) Explosive compounding, using the method of parallel end detonation to first compound a platinum plate 1 and a tantalum plate 3, after the surface is polished and smoothed, another platinum plate 2 and the primary compound plate 4 are compounded twice to form a secondary compound plate 5.

[0030] (4) The secondary clad plate 5 is rolled with a D550 type rolling mill, the processing rate of each pass is 10%-20%, the processing rate between two anneal...

Embodiment 3

[0034] Such as figure 1 and figure 2 As shown, taking the finished net platinum layer thickness of 0.1 mm as an example, the finished net size requires a platinum layer thickness of 0.1 mm, a tantalum layer thickness of 1 mm, and a net width of 50 mm.

[0035] The processing process is:

[0036] (1) Prepare the platinum plates 1 and 2, roll the platinum plates 1 and 2 into sheets with a thickness of 1.0 mm, and cut them into two sheets of 1.0×200×400 mm.

[0037] (2) A tantalum plate 3 with a size of 10×200×400 mm.

[0038] (3) Explosive compounding, using the method of parallel end detonation to first compound a platinum plate 1 and a tantalum plate 3, after the surface is polished and smoothed, another platinum plate 2 and the primary compound plate 4 are compounded twice to form a secondary compound plate 5.

[0039] (4) The secondary clad plate 5 is rolled with a D550 type rolling mill, the processing rate of each pass is 10%-20%, the processing rate between two annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com