Pulse electric field activated dry-type calcium-spraying flue gas desulfurization method and apparatus

A pulsed electric field and desulfurization device technology, applied in the field of environmental engineering, can solve the problems of insufficient utilization of desulfurizers, lower Ca/S ratio, and high operating costs, achieve simple and easy installation and actual operation, reduce residence time, and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Describe the specific embodiment of the present invention in detail below in conjunction with technical scheme and accompanying drawing description

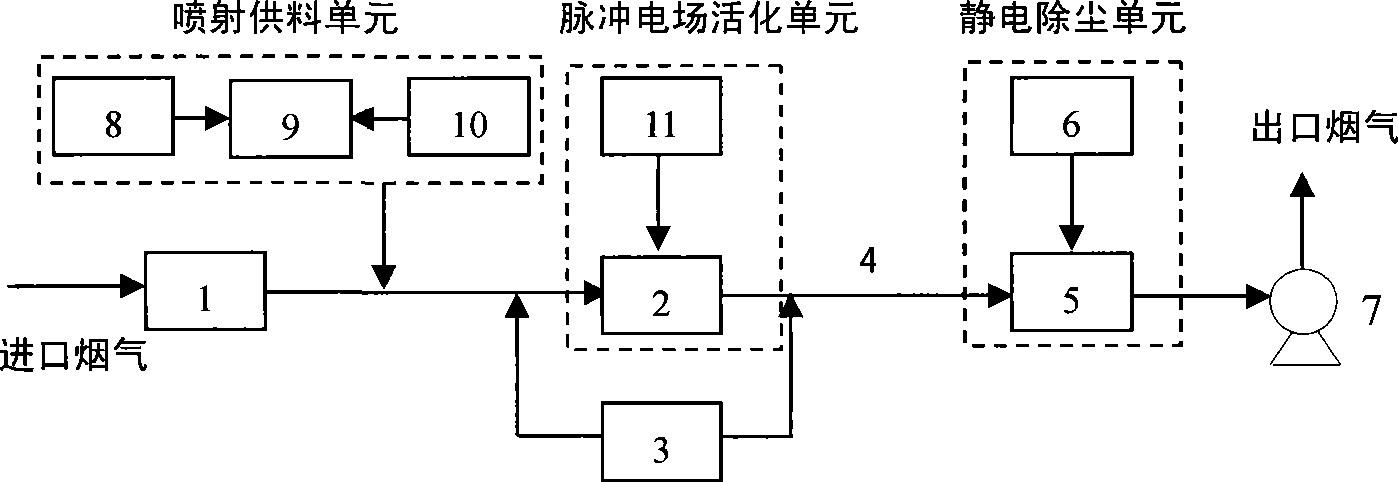

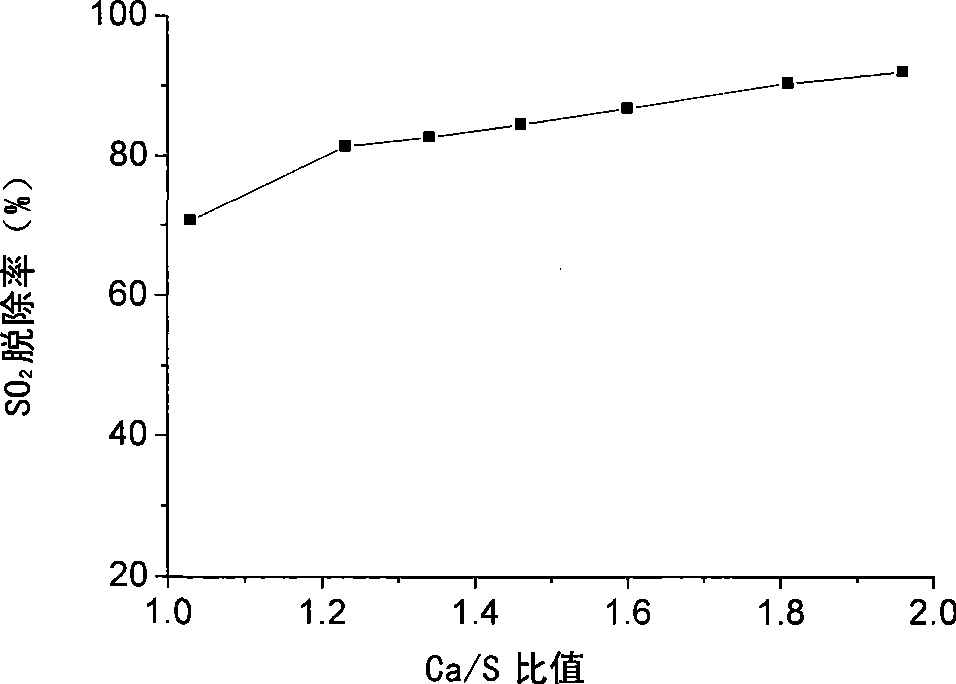

[0041] The pulse electric field activation dry calcium spray flue gas desulfurization process in the pipeline is as follows: figure 1 Shown, the desulfurizer Ca(OH) 2 In the injection feeding unit, spray it into the flue gas conveying pipeline 4 after the primary dust collector 1 (before the secondary dust collector 5) at high speed and contain SO 2 The flue gas is mixed, and then the Ca(OH) 2 with SO in flue gas 2 The reaction produces CaSO 3 and a small amount of CaSO 4 The particulate matter is then removed by the secondary dust removal equipment at the rear, so as to achieve the removal of SO in the flue gas 2 the goal of.

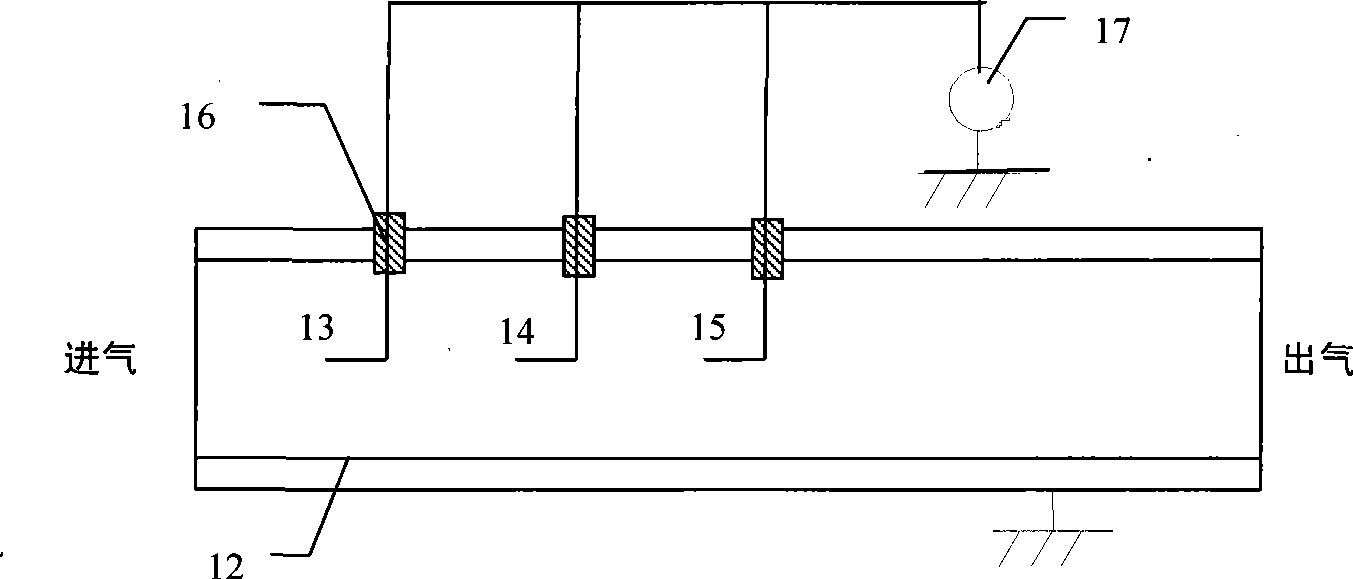

[0042] step 1: figure 1 , figure 2 The high-voltage pulse plasma power source 11 applies a high-voltage pulse voltage to the needle-shaped discharge electrodes 13, 14, and 15 in the pipeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com